6

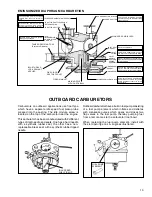

GENERAL CARBURETOR INFORMATION

When servicing carburetors, you may use either the

engine model specification number or the manufacturing

number on the carburetor to properly identify. Information

regarding replacement parts or kits are available in

the master parts manual, microfiche catalog or electronic

parts look-up systems.

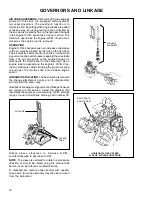

Tecumseh uses two basic types of carburetors for

their 2 cycle engines, float-type and diaphragm.

FLOAT-TYPE CARBURETORS

. Float-type carburetors

use a hollow metal float to maintain the operating

level of fuel in the carburetor. As the fuel is used, the

fuel level in the carburetor bowl drops and the float

moves downward. This actuates the inlet needle valve,

to allow fuel to flow into the fuel bowl. As the fuel

level in the bowl again rises, so will the float. This

float action adjusts the fuel flow and keeps the fuel

at the proper mixture level. Some carburetors are of

the fixed main type. On these models, the main adjusting

screw and nut are replaced by a fixed main jet bowl

nut.

DIAPHRAGM (PRESSURE DIFFERENTIAL)

CARBURETORS

This type of carburetor uses a rubber-like diaphragm

which is exposed to intake manifold pressure on one

side and to atmospheric pressure on the other. Tecumseh

diaphragm carburetors use the diaphragm as a metering

device. As the intake manifold pressure decreases

due to downward piston travel, the atmospheric pressure

on the vented side of the diaphragm moves the

diaphragm against the inlet needle. The diaphragm

movement overcomes the spring tension on the inlet

needle and moves the inlet needle off the seat. This

permits the fuel to flow through the inlet valve to maintain

the correct fuel volume in the fuel chamber. The inlet

needle return spring closes the inlet valve when the

pressure on the diaphragm equalizes or a pressure

higher than atmospheric exists on the intake side

(upward piston travel). The diaphragm meters a correct

fuel volume in the fuel chamber to be delivered to

the mixing passages and discharge ports.

A main or idle adjustment needle may be replaced

by an internally fixed jet on some models.

The main nozzle contains a ball check valve. The

main purpose of this ball check is to eliminate air being

drawn down the main nozzle during idle speeds and

leaning the idle mixture.

An advantage of the diaphragm carburetor over the

float system is that the diaphragm carburetor increases

the angle that the engine may be operated at.

ALTERNATE LOCATION

FOR MANUFACTURING NUMBER

CARBURETOR

MANUFACTURING NUMBER

CARBURETOR

CODE DATE

89 4 F 5

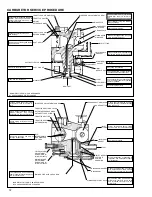

CHOKE

SHUTTER

FUEL

INLET

CHECK

BALL

DIAPHRAGM

MAIN

ADJUST

IDLE

ADJUST

AIR

BLEED

IDLE AND

INTERMEDIATE

PORTS

THROTTLE

SHUTTER

INLET

NEEDLE

AND

SEAT

INLET

SEAT

*MAIN ADJUST

FLOAT

INLET

NEEDLE

AIR

BLEED

CHOKE

SHUTTER

IDLE AIR

BLEED

IDLE FUEL

CHAMBER

THROTTLE

SHUTTER

SECONDARY IDLE

DISCHARGE

PRIMARY

IDLE DISCHARGE

*IDLE

ADJUSTMENT

SCREW

IDLE FUEL

TRANSFER PASSAGE

IDLE FUEL

TRANSFER

PASSAGE

REDUCTION ROD

CARBURETOR IDENTIFICATION.

Tecumseh carburetors

are identified by a manufacturing number and code

date stamped on the carburetor as illustrated.

*Both jets may be fixed - non adjustable

89 4 F5

Содержание AH520 -

Страница 67: ...64...