83-517-000 Rev.

A

50

5.15

PARALLEL OPERATION

Up to four units of the same

VOLTAGE

and

CURRENT

rating can be connected in parallel to provide up to four

times the output current capability. One of the units operates as a Master and the remaining units operate as

Slaves. The Slave units are analog programmed by the Master unit. In remote digital operation (RS-232/RS-485,

etc.), only the Master unit can be programmed by the controller while the Slave units may be connected to the

controller for voltage, current and status readback only.

There are two parallel operating methods,

Basic

and

Advanced

, to configure multiple power supplies for

parallel operation. With both parallel operating methods, power supplies should be connected in a Daisy-Chain

configuration. Refer to Sections 5.15.1, to Section 5.15.2, and to Section 5.16 for additional details.

Basic Parallel Operation

5.15.1

In this method, setting the units as

Master

and

Slaves

is made by the rear panel J1 connections and the setup

DIP-switch SW1. Each unit displays its own Output current and Output voltage. To program the load current, the

Master

unit should be programmed to the total load current divided by the number of units in the system. Refer

to the following procedure to configure multiple supplies for

Basic

parallel operation.

5.15.1.1 Setting up the Master Unit

Set the

Master

unit Output voltage to the desired voltage. Program the Output current limit to the desired load

current limit divided by the number of parallel units. During operation, the

Master

unit operates in CV mode,

regulating the load voltage to the programmed Output voltage. Connect the sensing circuit to local or remote

sensing as shown in Figure 5-4 or Figure 5-5.

5.15.1.2 Setting up the Slave Units

1. The Output voltage of all the

Slave

units should be programmed 2% - 5% higher than the Output voltage of

the

Master

unit to prevent interference with the

Master

unit’s control. The Output current limit of each unit

should be programmed to the desired load current limit divided by the number of paralleled units.

2. Set the rear panel setup DIP-switch SW1-2 to the

UP

position.

3. Set the rear panel setup DIP-switch SW1-3 to the same position as

SW1-4 of the

Master

unit.

4. Connect a wire jumper between J1-8 and J1-12 (refer to Table 4-4).

5. Connect J1-10 (IPGM) of the

Slave

unit to J1-25 (P) of the

Master

unit.

6. Connect J1-23 (IPGM_RTN) of the

Slave

unit to J1-12 (COM) of the

Master

unit.

During operation, the

Slave

units operate as a controlled current source that follows the

Master

unit Output

current. It is recommended that the power system be designed so that each unit supplies up to 95% of its Output

current rating because of the imbalance which may be caused by cabling and connection voltage drop.

5.15.1.3 Setting Over-Voltage Protection

The

Master

unit

OVP

setting should be programmed to the desired

OVP

level. The

OVP

setting of the

Slave

units should be programmed to a higher value than that of the

Master

unit OVP setting. When the

Master

unit

shuts down, it programs the

Slave

unit to zero Output voltage. If a

Slave

unit shuts down (when its

OVP

is set

lower than the

Master

unit Output voltage), only that

Slave

unit would shut down, and the remaining

Master/Slave

units would supply all the load current.

5.15.1.4 Setting Foldback Protection

FOLD

back protection, if desired, may only be used with the

Master

unit. When the

Master

unit shuts down, it

programs the

Slave

units to zero output voltage.

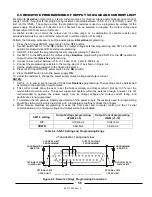

5.15.1.5 Connection to the Load

In parallel operation, power supplies can be connected with local or remote sensing. Refer to Figure 5-4 and 5-5

for typical connections of parallel power supplies. The figures show the connection of two (2) units, however the

same connection method applies for up to four (4) units.

Advanced Parallel Operation

5.15.2

In this method, multiple power supplies can be configured to parallel operation as a single power supply. The

total calculated load current and Output voltage are displayed by the

Master

unit and can be read back from the

Master

unit. The

Slave

units display only their operating status (ON, OFF or Fault condition). Refer to the

following procedure to configure multiple power supplies for

Advanced

parallel operation.

5.15.2.1 Basic Configuration

Repeat Steps 1 to 5 in Section 5.15.1 (

Basic

parallel operation).

Содержание GENESYS GEN 2400W Series

Страница 2: ...83 517 000 Rev A THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 3: ......

Страница 4: ......

Страница 6: ...83 517 000 Rev A THIS PAGE INTENTIONALLY LEFT BLANK ...

Страница 31: ...83 517 000 Rev A 21 2 15 GENESYSTM 2400W POWER SUPPLY OUTLINE DRAWING ...