94

Application

Product

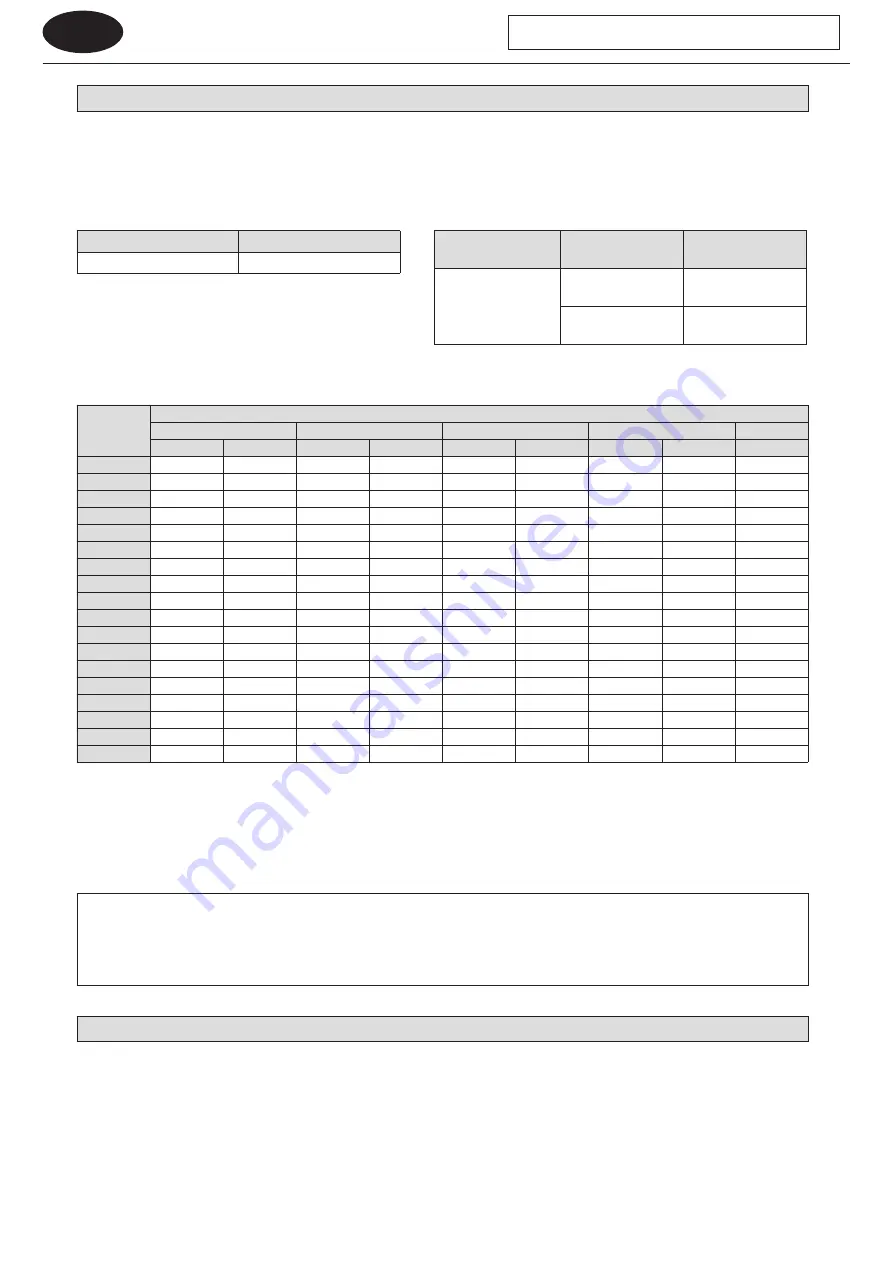

17. Daily Inspection and Maintenance

17-1 Base Unit Grease Replenishment

- All base unit bearings are grease lubricated. Units are shipped greased using the greases in Table 17-2, so they can be used as is.

- Make certain to perform maintenance. Neglecting maintenance is a source of problems.

(1) Grease Replenishment Intervals

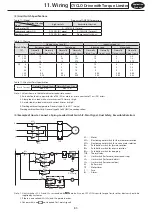

Table 17-1 Grease Replenishment Intervals

Part

Replenishment Interval

Base unit

1 time/2 – 3 years

(3) Grease Replenishment Quantity

Table 17-3 Grease Replenishment Quantity Guidelines (g)

Frame Size

Model

C14VM, C15VM

C17VM, C18VM

C24VM, C25VM

C27VM, C28VM

C3VM

Bearing A

Bearing B

Bearing A

Bearing B

Bearing A

Bearing B

Bearing A

Bearing B

Bearing

608

□

−

−

−

−

5

5

7

5

−

609

□

5

5

7

5

7

5

10

5

−

610

□

5

5

7

5

7

5

10

5

−

611

□

−

−

−

−

7

5

10

5

−

612

□

7

5

10

5

13

7

15

7

−

613

□

13

7

15

7

17

10

35

10

−

614

□

13

7

15

7

17

10

35

10

−

616

□

17

10

35

10

20

15

50

15

−

617

□

20

15

50

15

30

20

70

20

−

618

□

30

20

70

20

35

30

100

30

25

619

□

35

30

100

30

−

−

−

−

40

6205

−

−

40

35

−

−

−

−

−

6215

−

−

65

50

−

−

−

−

65

6225

−

−

65

50

−

−

−

−

65

6235

−

−

70

65

−

−

−

−

95

6245

−

−

125

85

−

−

−

−

−

6255

−

−

125

110

−

−

−

−

−

6265

−

−

210

150

−

−

−

−

−

Note : 1. The symbol

□

in frame size can be “0” or “5”. For double reduction and triple reduction types, DA, TA, etc. will be appended to the

frame size.

2.

Replenishment quantities are the same for double and triple reduction types.

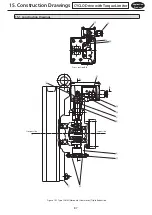

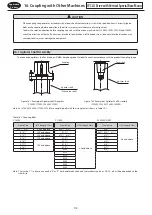

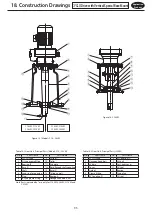

(4) Replenishment Procedure

Using a grease gun, replenish through grease fittings [2] and [8] (see P95, for C3VM, use [6]). See Table 17-3 for guidelines on quantity.

-If the product has not been operated for one year or longer, make certain to replenish grease before resuming operation.

-Grease while the machine is running to improve grease distribution.

-Replenish grease slowly.

-Contact the nearest authorized service station concerning a complete grease change.

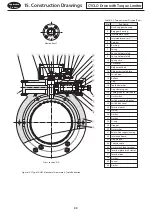

17-2 Main Unit Maintenance

Oil seals have lifetimes. During long use, natural degradation and frictional wear will reduce effectiveness. Reducer operating

conditions and ambient environment will cause lifetime to widely vary. Given normal operation, (uniform load, running 10 hours per

day, normal temperature) as a guideline it is recommended to change them every 1 to 3 years. If the sliding surfaces of oil seals or

V-rings show signs of wear or corrosion, replace them with new ones. Because sliding surfaces for oil seals are made of carbon steel,

take on-going rust prevention measures regularly not to spread rust on them by applying rustproof oil and so on, if there are exposed

surfaces of steel.

(2) Recommended Grease

Table 17-2 Recommended Grease (Grease Used when Shipped)

Ambient

Temperature °C

Manufacturer

Description

-10 to 50

COSMO

COSMO GREASE

DYNAMAX SH No.2

Mobil

UNIREX N2

CYCLO Drive with Vertical Special Base Mount