54

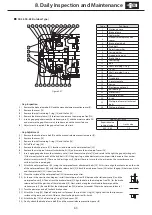

8. Daily Inspection and Maintenance

■

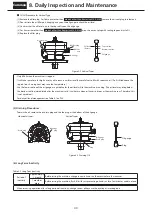

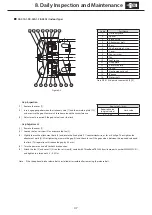

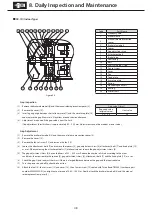

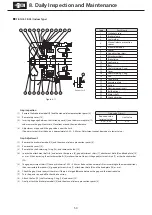

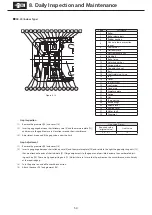

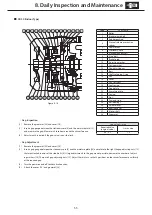

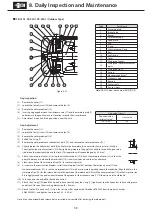

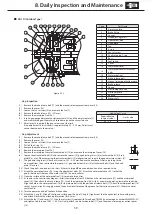

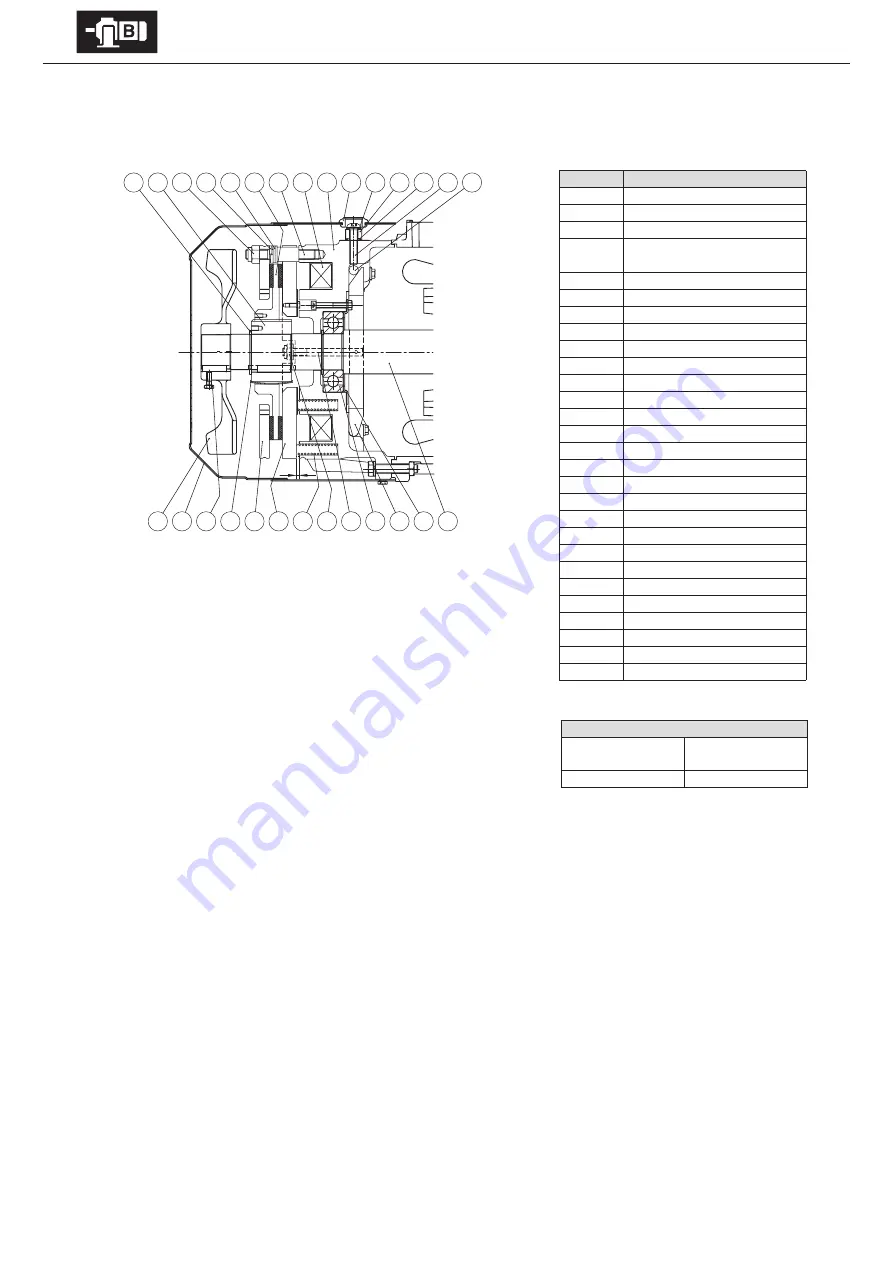

FB-20 (Indoor Type)

Code

Part Name

1

Roller

2

Brake release bolt

3

Rubber packing

4

Manual release prevention

spacer

5

Seal washer

6

Stationary core

7

Electromagnetic coil

8

Stud bolt

9

Brake lining

10

Adjusting washer

11

Spring washer

12

Gap adjusting nut

13

Boss

14

Shaft-retaining C-ring

15

Fan

16

Cover

17

Fan set screw

18

Leaf spring

19

Fixed plate

20

Armature plate

21

Spring

22

Nut

23

Tap-end stud

24

Ball bearings

25

Release lever

26

Bearing cover

27

Motor shaft

28

Grommet

1

2

3

4

5

28

6

7

8

9

10

11

12

13

14

17

15

18 19 20 21 22 23 24 25 26 27

16

G

-

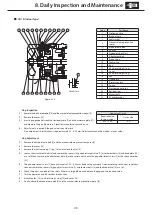

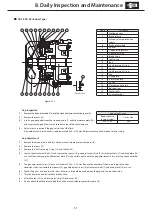

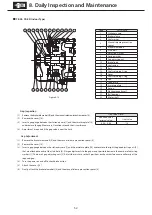

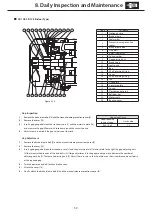

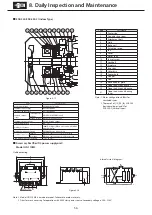

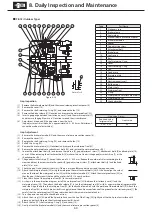

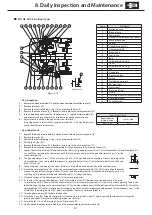

Gap Inspection

(1)

Remove the grommet [28] and cover [16].

(2)

Insert a gap gauge between the stationary core [6] and the armature plate [12],

and measure the gap. Measure in 3 locations around the circumference.

(3)

Adjustment is required if the gap value is near the limit.

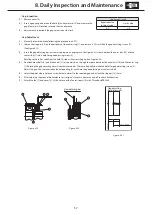

-

Gap Adjustment

(1)

Remove the grommet [28] and cover [16].

(2)

Insert a gap gauge between the stationary core [6] and the armature plate [20] and rotate to the right the gap adjusting nuts [12]

that are attached to ends of the stud bolts [8]. If large adjustments to the gap are not possible, decrease the number of adjust-

ing washers [10]. There are 3 gap adjusting nuts [12]. Adjust these in turn so that 3 positions on the circumference are uniformly

at the required gap.

(3)

Turn the power on and off to check brake action.

(4)

Attach the cover [16] and grommet [28].

Gap value G (mm)

Required value

(original value)

Limit value

0.6 – 0.7

1.5

Figure 8-15