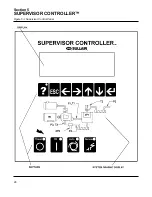

Section 5

SUPERVISOR CONTROLLER™

28

value. If during a change the ESC key is pushed,

editing is terminated and the original value is reset.

The left and right arrow keys can be used to move

to other digits or letters in a value. For example to

change a value from 100 to 500, the left arrow key

can be used to position the cursor to the 1 digit in

the 100, and the up arrow key used to increment

the digit to 5.

Text fields can also be edited in the same manner.

Push the enter key to start the edit, use the left and

right arrow keys to move to the letter to be changed,

then use the up and down arrow to change the let-

ter. Push the enter key to complete the edit.

The following are detailed descriptions of the vari-

ous displays.

5.4 STATUS - CURRENT PRESSURES, TEMPERA -

TURES, INPUTS AND OUTPUTS

All inputs and outputs are displayed showing both

the designator and the description (eg. T1-

Discharge) along with the selected temperature (C

or F) or pressure (psi, bar, kpa) units. Digital inputs

and outputs are shown either as a ‘0’ (zero) or ‘1’

(one). Zero is off and one is on. This is a view only

display.

The order of display is :

Temperatures -

T1 through T5 depending on

model

Pressures -

P1 through P4 depending on model

Delta pressures -

dp1 through dp3 depending on

model

Load Hours -

Hours machine has run loaded

Run Hours -

Hours machine has run loaded or

unloaded

Load Cycles -

Number of load/unload cycles

Starts -

Number of time machine has started

E-Stop String

- E-Stop push button.

Aux E-Stop -

Auxiliary E-Stop, wired by customer.

Digital Inputs -

D1 through D10, depending on

model

Relay Outputs -

K1 through K8, depending on

model

5.5 CONTROL PARAMETERS - PRESSURE, TEM-

PERATURE AND TIMER SETTINGS

Parameters that control the operation of the

machine are viewed and set using this display.

These parameters may vary by machine model.

The Control Parameters are :

Unload pressure -

The pressure where the

machine is unloaded. For example if this parameter

is set to 110 psi (7.6 bar) the machine will unload

when the line pressure is above 110 psi (7.6 bar).

Load delta -

The pressure differential below the

unload pressure where the machine is loaded. For

example if the unload pressure is set to 110 psi

(7.6bar) and the load differential is set to 10 psid

(0.7 bar), the machine will load when the line pres-

sure goes below 100 psi (6.9 bar).

Unload Time -

If the machine is running in AUTO

mode, this parameter specifies the amount of time

that the machine will run unloaded before shutting

off. If the time is set less than 15 minutes (for exam-

ple 5), there may be times when the machine will

run unloaded for more than 5 minutes. This is

because there is another timer that keeps the

machine from being started more than four times an

hour.

Drain Interval -

If the machine has an optional elec-

tric solenoid drain, this parameter and the following

parameter (Drain Time) are used to turn on the

drain. The interval is the time between activations of

the drain and the Drain Time is the length of the

time energized. This does not apply to the Sullair

SCD zero loss drain, which is not controlled or mon-

itored by the Supervisor.

Drain Time -

Length of time that drain is energized.

Restart time -

Enabling this function also enables automatic

restart after power recovery. Be sure to depress

the Emergency Stop button to defeat this func-

tion when automatic start is to be prevented.

Time to wait after power up before starting machine.

This parameter is used to keep several machines

from starting at the same time after power up, or to

delay start until other equipment is started. If dis-

abled parameter is zero, the machine will not auto-

matically start after power up. If this parameter is a

number larger than zero, the machine restarts after

a delay defined by this time. For example, if the

Restart Time is set to 10 seconds, then the machine

will be enabled to start after 10 seconds.

Wye to delta transition timer -

Also used to con-

trol the closed inlet start valve. Disable by setting to

zero (0)-full voltage start (standard for full voltage

start). Requires approximately 4-6 seconds for wye-

delta or solid state starting.

Modulate -

If set to “No” the spiral valve and inlet

valve modulation control are disabled, and the

Содержание LS-32

Страница 6: ...NOTES...

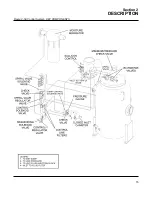

Страница 14: ...Section 2 DESCRIPTION 8 Figure 2 2 Compressor Piping and Instrument Diagram 02250140 998R02...

Страница 16: ...Section 2 DESCRIPTION 10 Figure 2 2 Compressor Piping and Instrument Diagram 02250140 998R02...

Страница 21: ...Section 2 DESCRIPTION 15 Figure 2 5A Control System KEY COMPONENTS...

Страница 22: ...Section 2 DESCRIPTION 16 Figure 2 5B Control System START...

Страница 23: ...Section 2 DESCRIPTION 17 Figure 2 5C Control System MODULATION...

Страница 24: ...Section 2 DESCRIPTION 18 Figure 2 5D Control System UNLOAD...

Страница 25: ...Section 2 DESCRIPTION 19 Figure 2 5E Control System FULL LOAD...

Страница 28: ...Section 3 SPECIFICATIONS 22 Figure 3 2 Identification LS 32 Air cooled 02250140 997R01...

Страница 32: ...Section 5 SUPERVISOR CONTROLLER 26 Figure 5 1 Supervisor Control Panel...

Страница 44: ...38 NOTES...

Страница 56: ...50 NOTES...

Страница 59: ...53 NOTES...

Страница 60: ...Section 8 ILLUSTRATIONS AND PARTS LIST 54 8 3 MOTOR COMPRESSOR FRAME AND PARTS 02250140 989R01...

Страница 62: ...Section 8 ILLUSTRATIONS AND PARTS LIST 56 8 3 MOTOR COMPRESSOR FRAME AND PARTS 02250140 989R01...

Страница 64: ...Section 8 ILLUSTRATIONS AND PARTS LIST 58 8 4 AIR INLET SYSTEM 02250140 990R02...

Страница 66: ...Section 8 ILLUSTRATIONS AND PARTS LIST 60 8 4 AIR INLET SYSTEM 02250140 990R02...

Страница 68: ...Section 8 ILLUSTRATIONS AND PARTS LIST 62 8 5 FLUID COOLING SYSTEM AIR COOLED 02250140 994R00...

Страница 70: ...Section 8 ILLUSTRATIONS AND PARTS LIST 64 8 5 FLUID COOLING SYSTEM AIR COOLED 02250140 994R00...

Страница 72: ...Section 8 ILLUSTRATIONS AND PARTS LIST 66 8 6 AIR PIPING SYSTEM AIR COOLED 02250140 992R01...

Страница 74: ...Section 8 ILLUSTRATIONS AND PARTS LIST 68 8 6 AIR PIPING SYSTEM AIR COOLED 02250140 992R01...

Страница 76: ...Section 8 ILLUSTRATIONS AND PARTS LIST 70 02250140 993R01 8 7 FLUID PIPING SYSTEM AIR COOLER...

Страница 78: ...Section 8 ILLUSTRATIONS AND PARTS LIST 72 02250140 993R01 8 7 FLUID PIPING SYSTEM AIR COOLER...

Страница 80: ...Section 8 ILLUSTRATIONS AND PARTS LIST 74 02250140 991R00 8 8 SUMP AND PARTS...

Страница 82: ...Section 8 ILLUSTRATIONS AND PARTS LIST 76 02250140 991R00 8 8 SUMP AND PARTS...

Страница 84: ...Section 8 ILLUSTRATIONS AND PARTS LIST 78 8 9 SULLICON CONTROL 02250134 158R00...

Страница 86: ...Section 8 ILLUSTRATIONS AND PARTS LIST 80 8 10 COMPRESSOR ACTUATOR...

Страница 88: ...Section 8 ILLUSTRATIONS AND PARTS LIST 82 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Страница 90: ...Section 8 ILLUSTRATIONS AND PARTS LIST 84 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Страница 92: ...Section 8 ILLUSTRATIONS AND PARTS LIST 86 8 11 PNEUMATIC CONTROLS 02250140 996R00...

Страница 94: ...Section 8 ILLUSTRATIONS AND PARTS LIST 88 8 12 CONTROL BOX SOLID STATE 02250122 005R04...

Страница 96: ...Section 8 ILLUSTRATIONS AND PARTS LIST 90 8 13 CONTROL BOX FULL VOLTAGE 02250122 511R04...

Страница 98: ...Section 8 ILLUSTRATIONS AND PARTS LIST 92 8 14 CONTROL BOX WYE DELTA 02250122 516R08...

Страница 100: ...Section 8 ILLUSTRATIONS AND PARTS LIST 94 8 15 ENCLOSURE AIR COOLED 02250140 995R00...

Страница 102: ...Section 8 ILLUSTRATIONS AND PARTS LIST 96 8 15 ENCLOSURE AIR COOLED 02250140 995R00...

Страница 104: ...Section 8 ILLUSTRATIONS AND PARTS LIST 98 8 16 DECAL GROUP...

Страница 106: ...Section 8 ILLUSTRATIONS AND PARTS LIST 100 8 16 DECAL GROUP...

Страница 108: ...Section 8 ILLUSTRATIONS AND PARTS LIST 102 8 16 DECAL GROUP...

Страница 110: ...Section 8 ILLUSTRATIONS AND PARTS LIST 104 8 17 DECAL LOCATIONS...

Страница 112: ...Section 8 ILLUSTRATIONS AND PARTS LIST 106 8 18 DECAL LOCATIONS ENCLOSURE...

Страница 114: ...Section 8 ILLUSTRATIONS AND PARTS LIST 108 8 19 DECAL LOCATIONS CONTROL BOX...

Страница 116: ...Section 8 ILLUSTRATIONS AND PARTS LIST 110 02250140 999R00 8 20 WIRING DIAGRAM AIR COOLED CUSTOMER SUPPLIED STARTER...

Страница 117: ...111 NOTES...