QUALITY DIRECTIVES

Page QUALITY DIRECTIVES-10

Z001007/0_4_September 2007

INSTALLATION INSTRUCTION

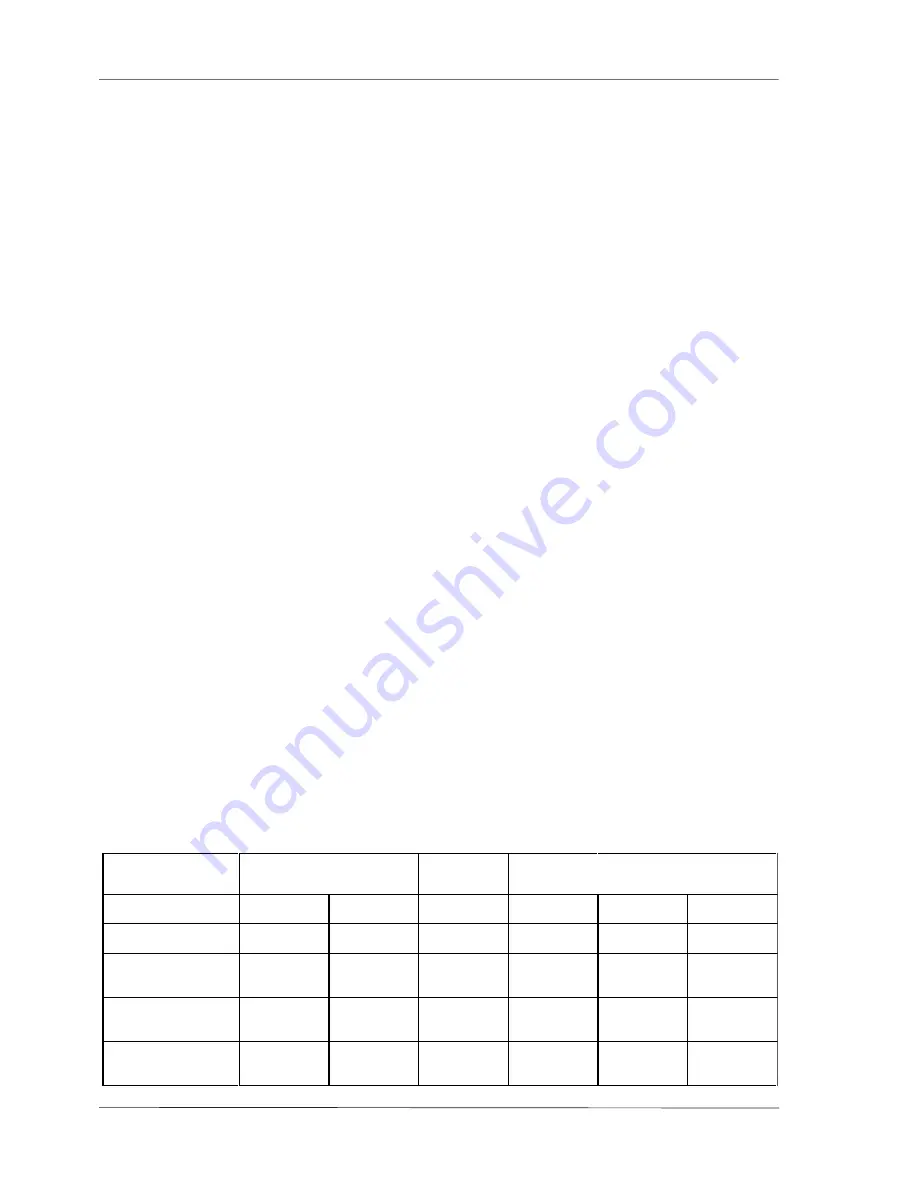

Use

Securing

Fixing

(B)

Sealing

Class

SM

SF

BF

DR

DF

DF

Product

Loctite 243

Loctite 262

Loctite 648

Loctite 572

Loctite 510

Loctite 620

Handtightness

reached after

15 - 30 min

15 - 30 min

5 - 10 min

15 - 30 min

immediately

immediately

Functional tightness

reached after

1 h

1 h

1 h

0.5 h

immediately

immediately

Final tightness

reached after

3 h

3 h

4 h

12 - 24 h

24 h

12 - 24 h

3.8.1. General Directions for Use of Aanaerobic Sealing Materials

Cleanliness of components

Non-metallic surface protection must be removed. In case of repair works, soiled and oily components are to be

cleaned and residues of adhesive synthetic are to be removed. Tapholes are recut with an appropriate tap and

blown off with compressed air.

If solvents or degreasing agents are used for cleaning, make sure that they have volatilized before application

of the synthetic.

Storage

At temperatures below 28° C, 1 year minimum.

Directions for securing (S)

Indication: SM ....... Medium-tight Securing (the connection can be loosened without problems)

Indication: SF ........ Tight Securing (the connection is difficult to loosen)

Application:

Screw joints

Fixing procedure

In general, it is sufficient to apply the synthetic on the screw thread.

If screws are screwed into socket threads, only wet the taphole in order to let the air escape during screwing.

Screws or nuts to be tightened with a specified torque are slightly oiled on their contact surface or housing

section.

Directions for fixing (B)

Indication: BM ....... Medium-tight Fixing

Indication: BF ........ Tight Fixing

Application:

Joint connections, sleeves, gear wheels, pulleys, bearings etc.

Jointing procedure

For jointing connections, both jointing parts are to be wetted. Wetting should completely cover the jointing

surfaces. In case of sliding fits, the parts are encased by turning.

No strength may be exerted to the connection until sturdiness is reached (for duration see table 1).

Directions for sealing (D)

Indication: DR ....... Sealing of pipe joint connections

Indication: DF ........ Sealing of plane surfaces

Application:

Sealing of threads, screwings, joint connections and plane surfaces.

Hardening time

Содержание 4 Cylinders

Страница 60: ...FUEL SYSTEM Page FUEL SYSTEM 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 7 FUEL SYSTEM NOTES ...

Страница 82: ...SAFETY COVERS Page SAFETY COVERS 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 11 SAFETY COVERS NOTES ...

Страница 86: ...BILGE PUMPS Page BILGE PUMPS 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 12 BILGE PUMPS NOTES ...

Страница 90: ...CABIN HEATING Page CABIN HEATING 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 13 CABIN HEATING NOTES ...

Страница 100: ...CONTROL STATION Page CONTROL STATION 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 15 CONTROL STATION NOTES ...

Страница 168: ...APPENDIX Page APPENDIX 2 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION 18 APPENDIX NOTES ...

Страница 170: ...APPENDIX Page APPENDIX 4 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION THIS PAGE IS INTENTIONALLY BLANK ...

Страница 172: ...APPENDIX Page APPENDIX 6 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION THIS PAGE IS INTENTIONALLY BLANK ...

Страница 173: ...Z001007 0_4_September 2007 Page APPENDIX 7 APPENDIX INSTALLATION INSTRUCTION ...

Страница 174: ...APPENDIX Page APPENDIX 8 Z001007 0_4_September 2007 INSTALLATION INSTRUCTION THIS PAGE IS INTENTIONALLY BLANK ...