© Titan Tool Inc. All rights reserved.

13

Solution

1. Inspect connections for air leaks.

2. Disassemble and clean.

3. Inspect and adjust.

4. Inspect and replace.

1. Replace.

2. Adjust.

3. Clean.

1. Check fluid supply.

2. Clean.

3. Replace.

Solution

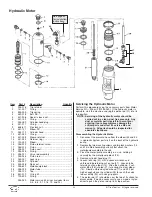

1. Remove foot valve assembly. Clean and

inspect. Test foot valve by filling with water;

if ball fails to seal the seat, replace ball.

2. Thin material — contact manufacturer for

proper thinning procedures.

3. Tighten all connections between pump and

paint container. If damaged, replace. Switch

to larger diameter siphon set.

1. Check upper seat and ball with water. If ball

fails to seal, replace seat.

2. Replace packing set if worn.

1. Refill with new material. If too thick, remove

siphon hose, immerse fluid section in

material, and start pump to prime. Add

thinner to material. Change to bigger

siphon set. Open bleed valve to remove

air and restart pump.

2. Remove foot valve. Clean ball and seat.

3. Straighten.

1. Check all connections between pump and

gun. Tighten as necessary. If material is

flowing from bleed hose, close bleed valve

or replace, if necessary. Should none of the

above be evident, replace lower packing.

2. Reseat balls by cleaning.

1. Replace.

2. Clean or replace filter.

3. Check electrical service. Correct as

required.

4. Increase hose size to minimize pressure

drop through hose and/or reduce hose

length.

1. Replace packing.

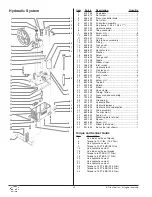

Cause

1. Air in system

2. Dirty gun

3. Needle assembly out of adjustment

4. Broken or chipped seat

1. Worn or broken needle & seat

2. Needle assembly out of adjustment

3. Dirty gun

1. No paint

2. Plugged filter or tip

3. Broken needle in gun

Cause

1. Lower foot valve ball is not seating due

to trash or wear

2. Material too viscous to siphon.

3. Air leaking in on siphon side or

damaged siphon hose. Siphon may be

too small for heavy material.

1. Upper ball is not seating due to trash or

wear

2. Lower packing set is worn

1. Material container is empty or material

is too thick to flow through siphon hose

2. Bottom ball stuck to foot valve seat

3. Siphon hose is kinked or loose

1. Loose connections. Bleed valve is open

partially or bleed valve is worn. Lower

packing seat is worn.

2. Upper and/or lower ball not seating

1. Spray tip is worn

2. Outlet filter or gun filter is clogged

3. Low voltage and/or inadequate

amperage

4. Hose size or length is too small or too

long

1. Solvent has caused upper packing to

swell

Airless Gun

Problem

Spitting gun

Gun will not shut off

Gun does not spray

Fluid Section

Problem

Pump delivers on upstroke

only or goes up slowly and

down fast (commonly called

downstroke dive)

Pump delivers on down stroke

only or goes up fast and down

slowly

Pump moves up and down

fast, delivering material

Pump moves up and down

slowly when spray gun is shut

off

Not enough fluid pressure at

gun

Pump chatters on up or down

stroke

Troubleshooting