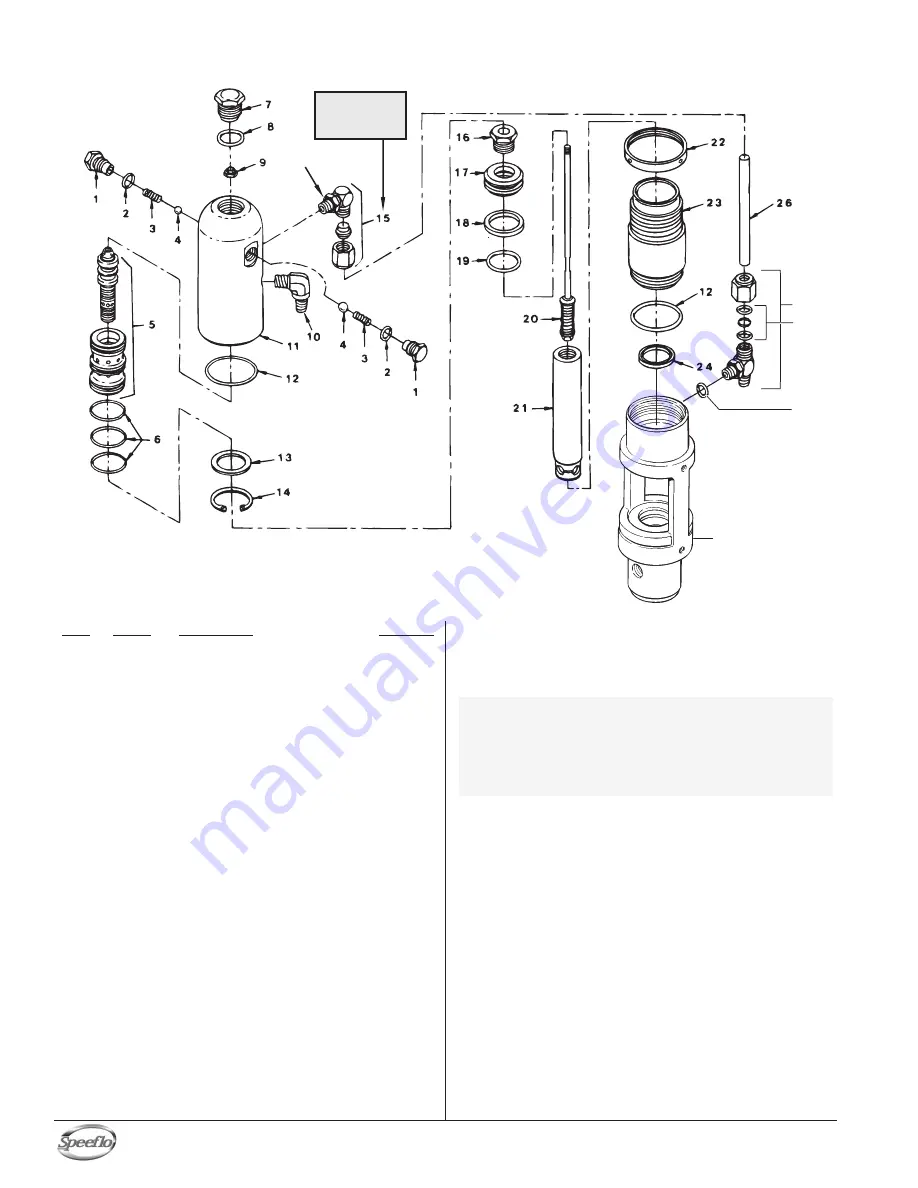

22

© Titan Tool Inc. All rights reserved.

29

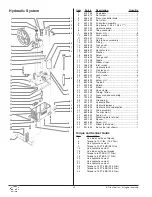

See page 30

for installation

instructions.

28

29

27

25

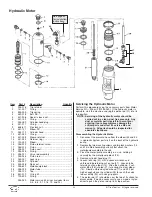

Item

Part #

Description

Quantity

1

235-018

Trip retainer ..............................................2

2

141-007

O-ring .......................................................2

3

325-005

Trip spring, ..............................................2

4

569-016

Ball, SS.....................................................2

5

441-908

Spool / sleeve set.....................................1

6

441-152

O-ring .......................................................3

7

235-030

Cylinder head plug ...................................1

8

441-217

O-ring .......................................................1

9

858-811

Flex lock nut .............................................1

10

451-121

Elbow, 90º ................................................1

11

235-112

Cylinder head ...........................................1

12

431-032

O-ring .......................................................2

13

431-053

Sleeve retainer .........................................1

14

431-054

Retainer ring.............................................1

15

192-000

Elbow........................................................1

16

235-022

Piston retainer screw................................1

17

235-014

Piston .......................................................1

18

235-027

Piston seal................................................1

19

235-026

O-ring .......................................................1

20

236-021

Valve rod assembly ..................................1

21

236-948

Piston rod .................................................1

22

235-001

Lock ring...................................................1

23

236-007

Cylinder ....................................................1

24

235-028

Rod seal ...................................................1

25

236-829

Motor/pump block.....................................1

26

236-029

Motor tube ................................................1

27

235-125

Tee............................................................1

28

431-019

O-ring kit...................................................1

29

700-499

O-ring .......................................................2

235-050

Motor service kit, minor (includes items

2–4, 6, 8, 9, 12, 18, 19, and 24)

Servicing the Hydraulic Motor

Perform this procedure using the necessary parts from Motor

Service Kit — Minor (P/N 235-050). If the hydraulic motor is

operable, start the machine and jog the piston rod (21) into its

top position.

Disassembling the Hydraulic Motor

1. Disconnect the pressure hose from the elbow (34 and 35

in Hydraulic System parts list) on the back of the hydraulic

pump.

2. Remove the two mounting screws and two lock washers (13

and 14 in Main Assembly parts list) that attach the

motor/pump assembly to the cart.

3. Place the motor/pump assembly in a vise, holding it

securely by the motor/pump block (25).

4. Remove cylinder head plug (7).

5. Loosen lock ring (22) with a spanner wrench and

unthread tube retaining nut on tee (27). Loosen tube

retaining nut on elbow (15). Slide the nut down. Push

motor tube (26) into tee (27) far enough to clear elbow

(15). Slowly unthread cylinder head (11) and Iift it just

high enough above the cylinder (23) to reach the valve

rod assembly (20) with vise grip pliers.

6. The piston rod (21) should be near the top of its stroke for

disassembly. It may be necessary to use a wood or nylon

driver to push the piston rod up to its top position.

NOTE: Servicing of the hydraulic motor should be

carried out in a clean, dust free area only. Any

dust or metallic particles left in the motor or

entering it on reassembly may damage the

critical parts and affect its service life and

warranty. All parts should be inspected for

absolute cleanliness.

Hydraulic Motor