For Machines Mfg. Since 8/11

Model SB1001 8K

™

Lathe

-39-

O P E R A T I O N

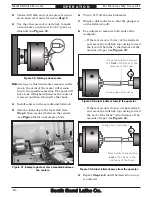

Selecting Spindle Speed Range

There are two ranges of available spindle speeds

that are selected by repositioning the drive

belt between the idler and spindle pulleys (see

Figures 47–48).

When the drive belt is in the outside position,

as shown in Figure 47, the low range of spindle

speeds (50–200 RPM) are available.

When the drive belt is in the inside position, as

shown in Figure 48, the high range (200–2400

RPM) of spindle speeds is available.

Tools Needed

Qty

Wrench 16mm .......................................................1

Wrench 17mm .......................................................1

Figure 47 . Drive belt between idler and spindle

pulleys in the low range position.

Belt

in Low

Range

Position

Idler

Pulley

Spindle

Pulley

To Change the Drive Belt Position:

1.

DISCONNECT LATHE FROM POWER!

2.

Open the end cover.

3.

Loosen the pivot block hex nut (see

Figure 49). This will allow the tensioning

bolt to change the position of the idler pulley

in the next step.

4.

Turn the tensioning bolt counterclockwise

to raise the idler pulley and release the belt

tension.

5.

Roll the belt from the current position on the

idler and spindle pulleys to other position

(outside for the low range and inside for the

high range).

Important:

Make sure the belt is positioned

across the full width of the pulleys and the

ribs of the belt are fully seated in the pulley

grooves.

6.

Apply moderate pressure on the idler

pulley toward the front of the lathe (see

Figure 49) while tightening the tensioning

bolt clockwise.

Figure 49. Drive belt tensioning controls.

Pivot

Block

Apply

Pressure

Here

Idler

Pulley

Tensioning Bolt

Figure 48. Drive belt between idler and spindle

pulleys in the high range position.

Belt in

High Range

Position