– 13 –

10. Backlight Consumed Current Adjustment

Set the brightness of backlight.

If deviated, the picture will be too dark or too bright.

Item number

3-01-09

Screen display

Color bar

Measurement point

+ probe: Adjusting monitor jig

I

pin

(BL+)

_ probe: Adjusting monitor jig

H

pin

(BL–)

Measuring instrument

Digital voltmeter

Adjustment data

B6

initial value

Adjustment value

A = 66.0

±

1.0 mV

Note:

Use AC adapter whenever performing this adjustment.

After turning on the power, wait for more than 30 seconds,

and then start the adjustment.

Adjusting method

1) Select the item number “3-01-09”.

2) Press the MENU key to display color bar on the LCD screen.

3) Using

e

and

E

keys, change the adjustment data so that po-

tential difference (A) between adjusting monitor jig

I

pin

(BL+) and

H

pin (BL–) satisfies the adjustment value.

4) Press

y

key to write the adjustment data.

5) Press the MENU key to return the LCD screen to the test mode

screen.

11. White Balance Adjustment

Adjust the white balance properly.

If deviated, the color reproducibility of LCD screen will be poor.

Item number

3-01-0A

Screen display

10-step gradation pattern (white/black)

Measurement point

Check on the LCD screen

Measuring instrument

Adjustment data

R data: 95

initial value

B data: 70

Adjustment value

LCD screen must not be colored

Note:

To switch between R data and B data, press

u

key.

After the adjustment finished, move to other item with R

data kept displayed.

Adjusting method

1) Select major item number “2” (EVF), and set the 10-step gra-

dation pattern (white/black).

2) Select the item number “3-01-0A”.

3) Set the adjustment data to initial value (R data:95, B data:70).

Note:

Each time the data is set, press

y

key to write data to

nonvolatile memory.

4) Press the DSPL key to display the 10-step gradation pattern

(white/black) on the LCD screen.

5) Check that the LCD screen is not colored.

If colored, change the adjustment data by using

e

and

E

keys

so that the LCD screen is not colored.

Note:

Each time the data is set, press

y

key to write data to

nonvolatile memory.

6) Press the DSPL key to return the LCD screen to the test mode

screen.

1-4.

Servo System Adjustment

1. Servo Auto Adjustment

The servo auto adjustment is executed automatically so that the

adjustment data of the servo system meets the optical pick-up block

in that set.

The servo auto adjustment checks the type of inserted disc and

executes automatically the adjustment that meets the inserted disc.

If the optical pick-up block or IC5405 on the Main board was

replaced, perform the servo auto adjustment with the following

three types of discs respectively.

• MD1 High reflectance pre-mastered disc (TDYS-1)

Part code: 4-963-646-01

• MD1 MO disc

Commercially available SONY MD1 MO disc (already recorded)

• MD2 MO disc

Commercially available SONY MD2 MO disc

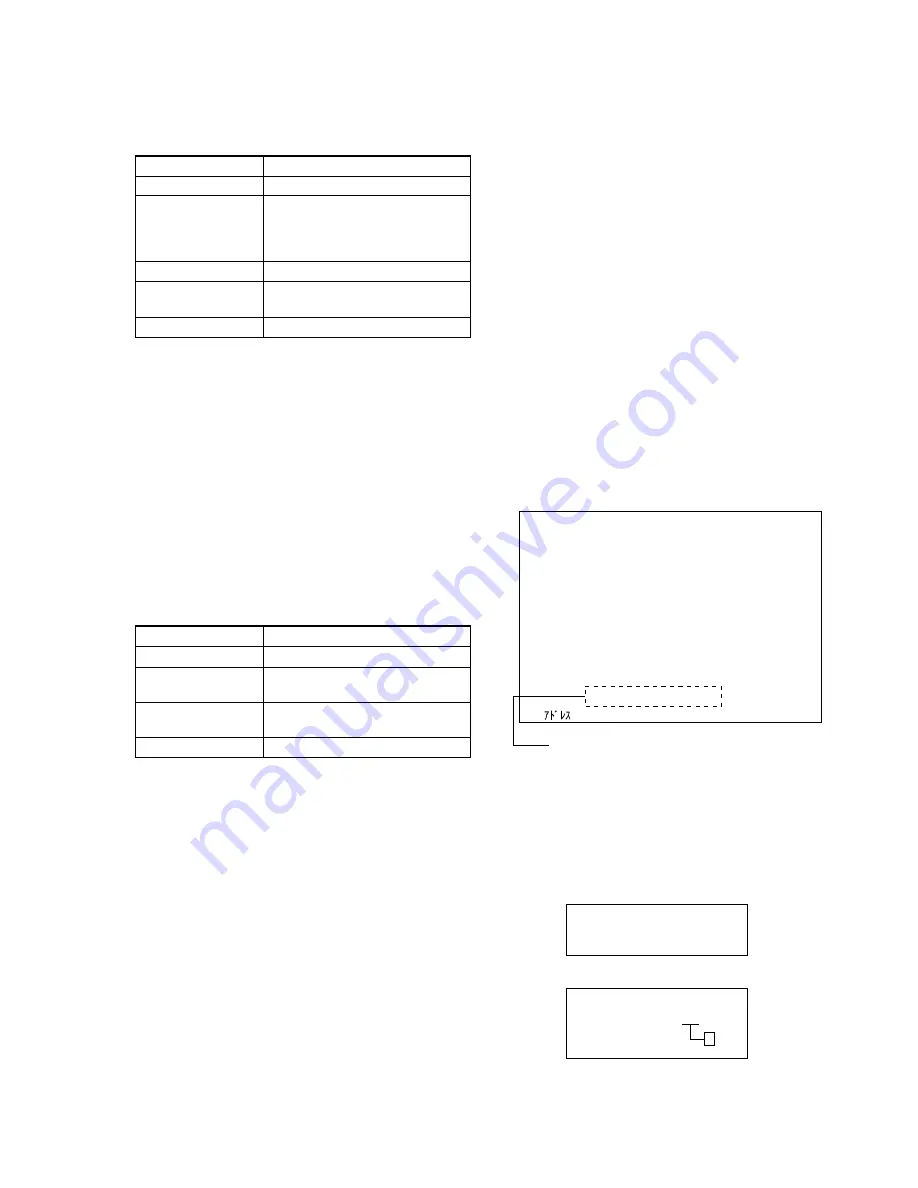

Adjusting method

1) Select the item number “8-01-01”.

2) Insert the desired type of disc to be adjusted.

3) Press

y

key to execute the servo auto adjustment. (Auto ad-

justment will start and “Now Adjusting ...

ss

” will be dis-

played in the adjustment status display field.)

Note:

Place the set horizontally and perform adjustment un-

der stable condition.

Fig.7-1-18

4) At the completion of adjustment, the adjustment result will be

displayed in the adjustment status display field.

Note:

If an error occurs during adjustment, you can check

the item name where the error occurred. (Refer to

“Faulty item checking method”.)

Fig.7-1-19

5) Remove the disc inserted in step 2).

TEST MODE

Servo

made by MD dep.

I TRON

Ver.

s

.

sss

Drive

Ver.

s

.

sss

JAVA APP

Ver.

ssssssss

JAVA OS

Ver.

ssssssss

BOOT

Ver.

s

.

sss

I PL

Ver.

s

.

sss

RATE CTL

Ver.

s

.

sss

Item No.

All Adjust START

Now Adjusting . . .

ss

8–01–01

Servo Common

: 6C0 DATA : 00 00 00 30 00 00 00 00

Adjustment status display field

NG

OK!

NG.

ss

ss

• In case of successful adjustment

• In case of NG adjustment

A

Содержание MDDISCAM DCM-M1

Страница 5: ...1 1 SECTION 1 GENERAL This section is extracted from in struction manual 3 866 152 11 DCM M1 ...

Страница 6: ...1 2 ...

Страница 7: ...1 3 ...

Страница 8: ...1 4 ...

Страница 9: ...1 5 ...

Страница 10: ...1 6 ...

Страница 11: ...1 7 ...

Страница 12: ...1 8 ...

Страница 13: ...1 9 ...

Страница 14: ...1 10 ...

Страница 15: ...1 11 ...

Страница 16: ...1 12 ...

Страница 17: ...1 13 ...

Страница 18: ...1 14 ...

Страница 19: ...1 15 ...

Страница 20: ...1 16 ...

Страница 21: ...1 17 ...

Страница 22: ...1 18 ...

Страница 23: ...1 19 ...

Страница 24: ...1 20 ...

Страница 25: ...1 21 ...

Страница 26: ...1 22 ...

Страница 27: ...1 23 ...

Страница 28: ...1 24 ...

Страница 29: ...1 25 ...

Страница 30: ...1 26 ...

Страница 31: ...1 27 ...

Страница 32: ...1 28 ...

Страница 33: ...1 29 ...

Страница 34: ...1 30 1 30 E ...

Страница 47: ...2 13 MEMO ...

Страница 69: ...DCM M1 4 5 4 6 4 7 4 8 4 1 FRAME SCHEMATIC DIAGRAM FRAME ...

Страница 96: ...DCM M1 4 115 4 113 4 114 ETHER INTERFACE ETHER ...

Страница 98: ...DCM M1 4 119 4 120 AV IN OUT JACK JACK AV IN OUT SCHEMATIC DIAGRAM See page 4 121 for printed wiring board ...

Страница 99: ...DCM M1 4 121 JACK AV IN OUT PRINTED WIRING BOARD Ref No JACK board 20 000 series 4 122 AV IN OUT JACK ...

Страница 173: ...DCM M1 33 34 35 LCD LCD Signal Paths were Missing in Service Manual LCD LCD SCHEMATIC DIAGRAM Page 4 106 to 4 108 ...

Страница 196: ... 22 FOR CAMERA OPTICAL AXIS ADJUSTMENT 0 180 90 67 5 22 5 337 5 292 5 247 5 202 5 157 5 112 5 8 4 5 7 1 6 2 3 270 ...