Doc. no.IZ

*

-OMV0005

5

1) This product is intended for use in general factory automation equipment.

Consult SMC before using this product for other intentions. (See Warning No. 4 on page 3)

2) Use within the specified voltage, temperature and humidity range.

Operation with a voltage, temperature or humidity other than those specified can cause malfunction,

damage to the product, electric shock or fire.

3) Use clean compressed air as fluid. (Air quality Class 2.6.3 specified in ISO 8573-1: 2001 is

recommended.)

Never use flammable or explosive gas as fluid. This may lead to fire or explosion. Please contact us when

fluids other than compressed air are used.

4) The product is not designed to be explosion proof.

Never use in an atmosphere of potential dust explosion, flammable gas or explosive gas. It may cause fire.

1) Clean room specification is not available.

This product has not been cleaned. When using in a clean room environment, confirm the required

cleanliness before use. Fine particles are generated due to wear of emitters and motor sliding during

operation.

1) Provide adequate space for maintenance, piping and wiring.

Install the product with consideration for the connector mounting, emitter cartridge assembly for cleaning of

the emitter, and one-touch fitting for supplying compressed air, so that there is enough space for mounting

and removal of the power cable, cartridge assembly and air tubing and for emitter maintenance, inspection

and wiring.

To avoid applying unreasonable stress to the connector and one-touch fitting, ensure any bends in the

cable or air tubing are greater than the minimum bending radius. If the cable or air tubing is bent at an acute

angle or repeated load is applied to the cable, it may cause malfunction, wire damage or fire.

2) Mount the product to a flat surface.

Mounting on an uneven surface will apply excess force to the frame or case, which leads to damage or

failure. Do not drop or apply excessive shock. Otherwise, damage or an accident may occur.

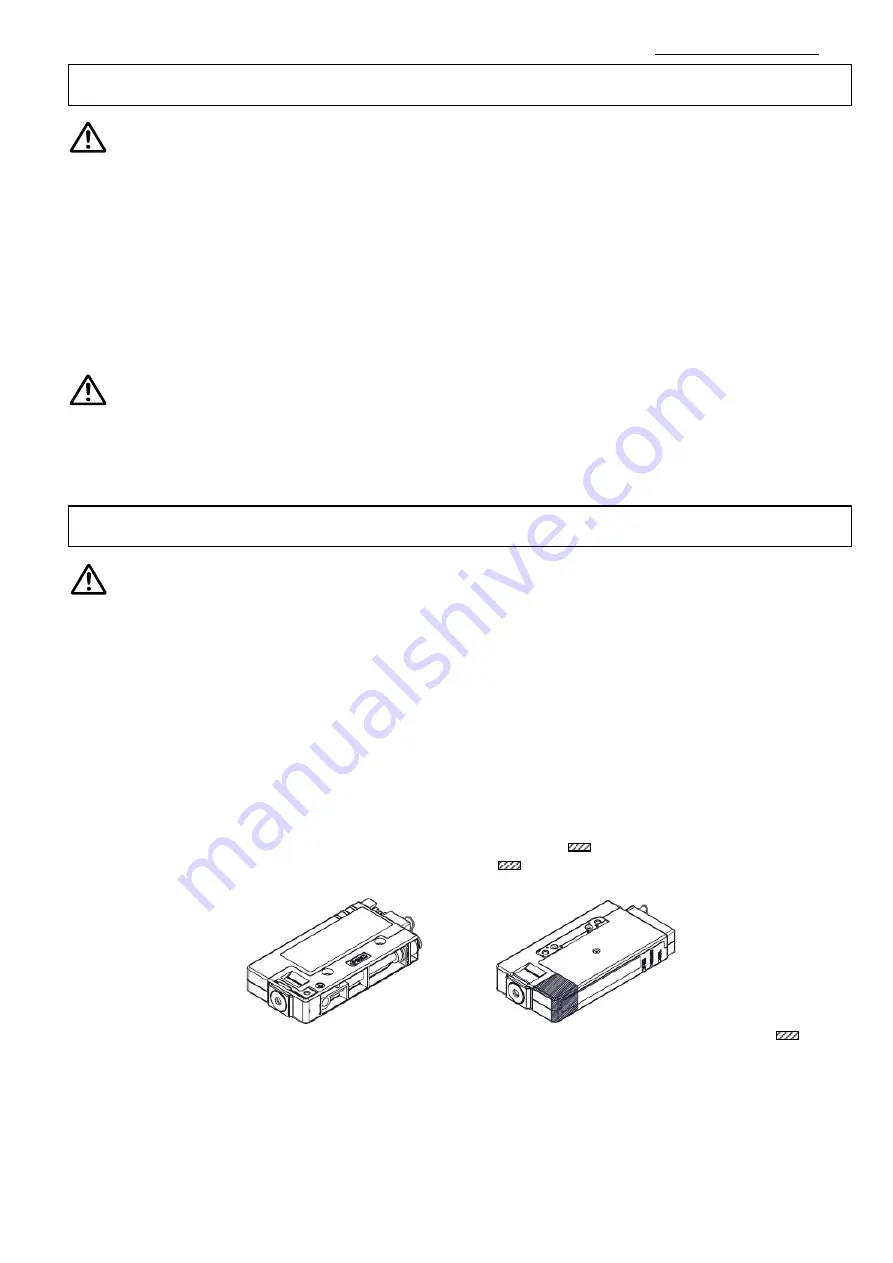

3) Keep the area specified clear when the product is mounted directly on to a base or workpiece which

are connected to ground.

Mount the product with the base or work piece avoiding the area (

shaded) in the drawing below. If the

grounded base or workpiece is too close to the area (

shaded), ozone concentration may increase

depending on the operating conditions, causing failure of the product.

4) Avoid using in a place where noise (electromagnetic wave and surge) is generated.

If the product is used in an environment where noise is generated, it may lead to deterioration or damage of

the internal elements. Take measures to prevent noise at its source and avoid power and signal lines from

coming into close contact.

5) Use a correct tightening torque.

If the screws are tightened in excess of the specified torque range, it may damage the mounting screws,

mounting brackets, etc. If the tightening torque is insufficient, the mounting screws and brackets may become

loose.

Mounting

Selection

Refer to page 28 Dimensions for dimensions of the area ( shaded).

Warning

Caution

Warning