Service and maintenance

7.2 Tests during inspections and after tripping

Air circuit breaker 3WL10

170

Manual, 11/2017, L1V30499596002-01

7.2

Tests during inspections and after tripping

The following tests must be conducted during inspection, after tripping, and after lengthy

storage under certain environmental conditions before re-commissioning. These can be

performed with a TD310 test device to power the ETU. They are not absolutely necessary

after delivery from the factory because the devices are 100 % tested before shipment. A

trip test confirms correct mechanical functioning of the tripping plunger on the trip coil,

actuated by the ETU. Electronic monitoring of the entire connection between the current

transformers, ETU, and trip coil is performed continuously by the electronics itself

(watchdog).

Items to be tested

Checks

Enable alarms

Connect the ETU to a test device and check that no alarms are

present.

Status of the circuit

breaker

On the ETUs of the 3-series, the status of the circuit breaker must not

be incorrect (see tables of the LED display in Chapter Alarms

(Page 161)). Perform a close/open operation on the circuit breaker

and check that no alarms have occurred.

On the ETUs of the 6-series, the status of the circuit breaker must be

correctly shown on the display. Perform a close/open operation on the

circuit breaker and check that the change in circuit breaker status is

correctly displayed.

Trip test

Make a trip attempt with the circuit breaker closed during an idle

period (without circulating currents of the mains connection) and

check that the circuit breaker opens.

7.3

Maintenance intervals

Environment with standard conditions

Following initial commissioning, the equipment/system must be serviced at least once per

year or after 2000 switching operations.

Note

These maintenance intervals also apply to circuit breakers that are used irregularly or that

remain in the same switch position for long periods.

Dusty environment

If the circuit breaker is operated in a dusty environment (dust component > 1 mg/m

3

), it

should be maintained at least twice a year or after 1000 switching operations.

Содержание SENTRON 3WL10

Страница 1: ......

Страница 2: ......

Страница 8: ...Table of contents Air circuit breaker 3WL10 6 Manual 11 2017 L1V30499596002 01 ...

Страница 14: ...Introduction 1 3 Safety instructions Air circuit breaker 3WL10 12 Manual 11 2017 L1V30499596002 01 ...

Страница 21: ...Description 2 2 Possible uses and portfolio Air circuit breaker 3WL10 Manual 11 2017 L1V30499596002 01 19 ...

Страница 108: ...Accessories 3 5 Breaker Data Adapters and test devices Air circuit breaker 3WL10 106 Manual 11 2017 L1V30499596002 01 ...

Страница 128: ...Application planning 4 3 Communication planning Air circuit breaker 3WL10 126 Manual 11 2017 L1V30499596002 01 ...

Страница 152: ...Connection and commissioning 5 4 Commissioning Air circuit breaker 3WL10 150 Manual 11 2017 L1V30499596002 01 ...

Страница 170: ...Operation 6 3 Troubleshooting Air circuit breaker 3WL10 168 Manual 11 2017 L1V30499596002 01 ...

Страница 180: ...Technical specifications Air circuit breaker 3WL10 178 Manual 11 2017 L1V30499596002 01 ...

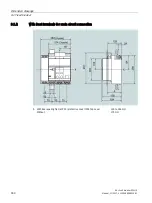

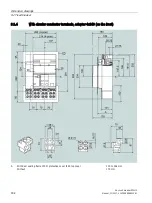

Страница 198: ...Dimension drawings 9 2 Withdrawable breaker Air circuit breaker 3WL10 196 Manual 11 2017 L1V30499596002 01 ...

Страница 199: ...Air circuit breaker 3WL10 Manual 11 2017 L1V30499596002 01 197 Circuit diagrams 10 ...

Страница 212: ...Circuit diagrams Air circuit breaker 3WL10 210 Manual 11 2017 L1V30499596002 01 ...

Страница 230: ...List of abbreviations C 1 Table of abbreviations Air circuit breaker 3WL10 228 Manual 11 2017 L1V30499596002 01 ...

Страница 233: ......

Страница 234: ......