32

IMPORTANT POINTS!

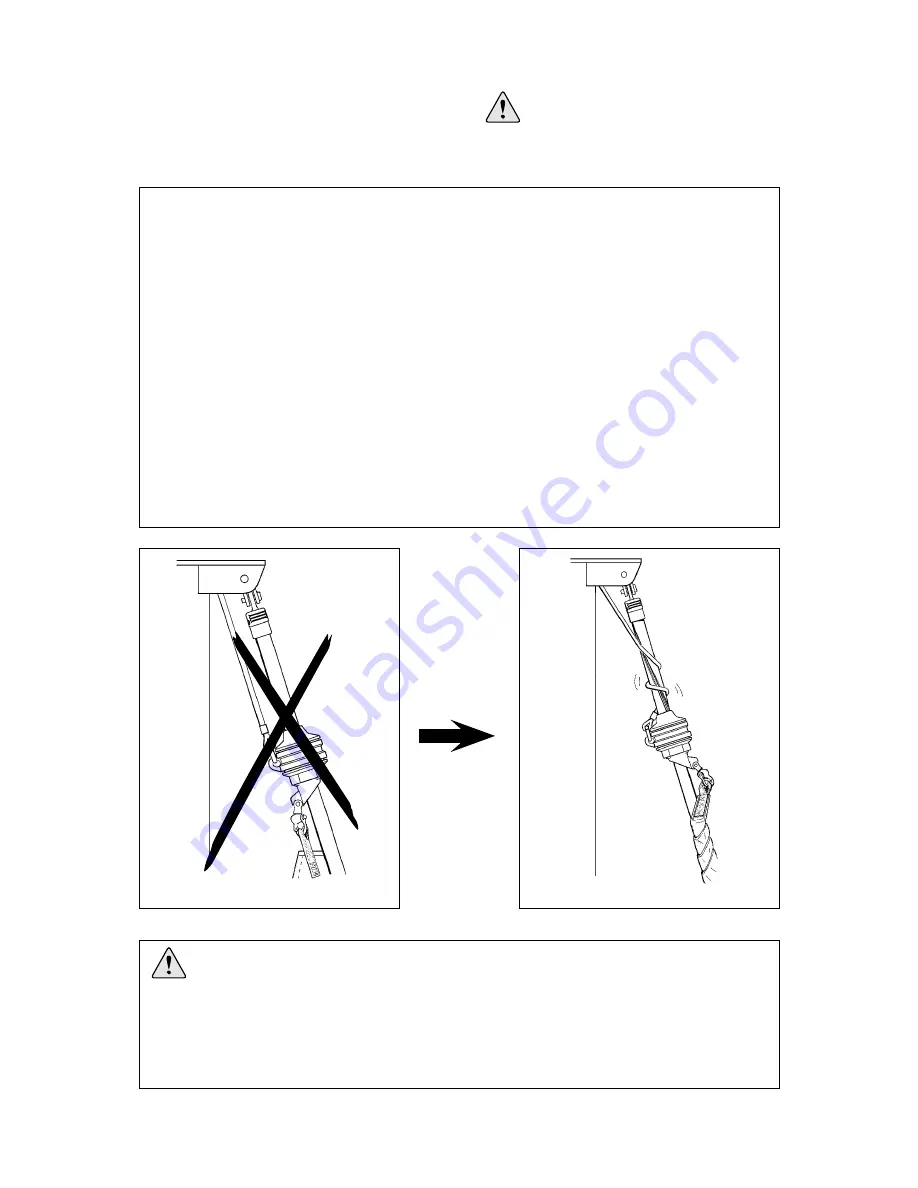

Routing the halyard is one of the most important aspects of system assembly for safe, trouble-

free

sailing using the jib furling and reefing system.

The angle between the halyard and the forestay must be 5 - 10°. See fig. 5.4.b. If the angle is less,

the halyard may wrap around the luff section when the sail is being furled, possibly damaging the

halyard and the luff extrusion. Failure to observe what is happening in this situation may even

result in damage to the forestay wire.

”Halyard wrap” may cause severe damage to the forestay and put the entire rig at risk. If the sail

is furled with the aid of a winch, take great care. It can be difficult to control the tension in the

furling line.

If the 5 - 10° requirement is not satisfied, halyard leads or a sheave box must be fitted to avoid

halyard wrap.

2 halyard leads are enclosed in the Furlex kit. Check if these are fitted.

See also under

”Halyard routing”

, chap. 5.

Fig. 10.1.b

Fig. 10.1.a

When sailing, movement occurs between the wire halyard and the halyard lead.

To prevent halyard wear, the halyard lead is made of bronze. This is a softer material

than a wire halyard, so the halyard lead will wear before the wire.

Halyard leads should be inspected once a year and any sharp edges smoothed with a

file. The halyard lead should be replaced when wear reaches 50%.

The halyard leads are not covered by the 5 year Furlex warranty.

May lead to

10 Halyard Routing

10.1 Summary