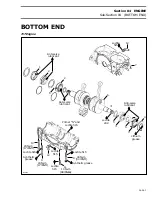

Section 04

ENGINE

Sub-Section 04

(BOTTOM END)

04-04-10

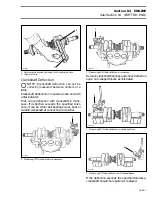

CAUTION : On 717 engine, temporarily

install armature plate to align crankcase

halves with each other.

8,9, Screw

Apply Loctite 515 on screw threads and synthetic

grease below head screws.

717 Engine

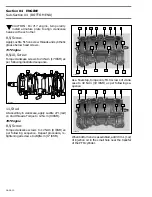

8,9,10, Screw

Torque crankcase screws to 24 N•m (17 lbf•ft) as

per following illustrated sequence.

11, Stud

At assembly in crankcase, apply Loctite 271 (red)

on stud threads. Torque to 12 N•m (9 lbf•ft).

787 Engine

8,9, Screw

Torque crankcase screws to 12 N•m (9 lbf•ft) as

per following sequence. Repeat procedure, re-

tightening all screws to 24þN•m (17 lbf•ft).

As a final step, torque only M10 screws of crank-

case to 40 N•m (30 lbf•ft) as per following se-

quence.

When bottom end is assembled, add 30 mL (1 oz)

of injection oil in the small hole near the transfer

of the PTO cylinder.

-

F01D20A

12

7

1

11

3

9

5 13

14

6

10

2

4

8

F01D81A

7

21

1

3

5

22

9

10

6

2

4

8

13

12

14

18

20

11

19

17

15

16

11

7

1

3

5

9

10

6

2

4

8

12

F01D81B

Содержание Challenger 5896

Страница 1: ......

Страница 2: ......

Страница 3: ...219 100 044 0 0 0 1996 Shop Manual 0 R ...

Страница 143: ...Section 08 ELECTRICAL Sub Section 01 OVERVIEW 08 01 3 1 Battery 2 Fuse block 3 Accessories F04H0YA 3 1 2 ...

Страница 152: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 2 ELECTRICAL BOX Sportster F04H11S ...

Страница 154: ...Section 08 ELECTRICAL Sub Section 03 IGNITION SYSTEM 08 03 4 ELECTRICAL BOX Speedster F04H26S ...

Страница 251: ...Section 11 HULL DECK Sub Section 01 COMPONENTS 11 01 5 F04L3IS Loctite 242 ...

Страница 274: ......