30.30.01.01839/03

www.schmalz.com

9 | EN

1

2

3

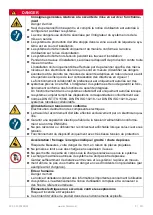

Pneumatic Connection

1. Electrical connection

2. Pneumatic connection

3. Blow-off opening

The compressed air is connected using the plug-in screw union for compressed air hoses, which is

located on the sealing plate and is included in delivery. Requirements for the compressed air pro-

vided by the customer:

Dry, filtered air according to ISO 8573-1:2010 [7:4:4]

Constant operating pressure: 5.5 bar.

If you select a supply hose that is too small, the compressed air supplied to the pneumatic ele-

ments will not be enough for optimal operation.

Compressed air supply

The gripper type FXCB requires 161.5 l/min of compressed air. The compressed air

supply integrated into robots is generally not sufficient.

Ventilation

The openings along the housing of the gripper serve as outlets for the exhaust air

from the ejectors (only FXCB). In order to maintain the gripper’s functionality, these

openings may not be closed or covered.

Vacuum Connection (only FMCB)

1. Hose connection

2. Hose clamp

A hose that is suitable for vacuum applications must be connected at the installed hose connection

and secured with the included hose clamps. The supply hose must have the same nominal diame-

ter as the installed connection. The maximum recommended hose length is around 10 meters.

For instructions on opening the housing, see chapter 8.7

of the complete operating instructions.

Vacuum

Once vacuum is applied in a gripper, it immediately begins suction.

2

1