8

ENGLISH

re the insulation resistance of the motor and cable several times

(2 Mohms minimum).

5.2 Hydraulic connections (See FIG. 4)

Installation diagram

1 -

D400 Immerson pump.

2 -

Earth electrode.

3 -

Dry-running electrode.

4 -

Upper electrode.

5 -

Motor supply cable.

6 -

Dynamic level (pump ON).

7 -

Static level (pump OFF).

8 -

Protection box (with dry running).

9 -

Mains supply.

10 -

Pressure switch.

11 -

Bladder tank.

12 -

Insulation valve.

13 -

Non return valve.

14 -

Electric cable connected with the motor.

15 -

Connexion between cables (

items 5 and 14

).

16 -

Clamp fixation of the pipe.

• On threaded steel rigid pipes 1"

1/4

or 2" according to models. In case of

flexible pipe the pump has to be supported with a cable secured to

both lifting eyes located on the delivery pump housing.

• The installation of a non-return valve (

item 13

) at the outlet of the

borehole (between pump and installation) is recommended.

• Plan a pressure gauge or contactor and insulation valve at the

borehole or well outlet.

5.3 Electrical connections

Electric connection and inspections muts be carried out by a

qualified electrician and comply with applicable local stan-

dards.

- Check the voltage available on the mains.

- Use a cable conforming to the standards in force.

The maximum cable length depends on the motor current

and the allowed voltage drop over this length.

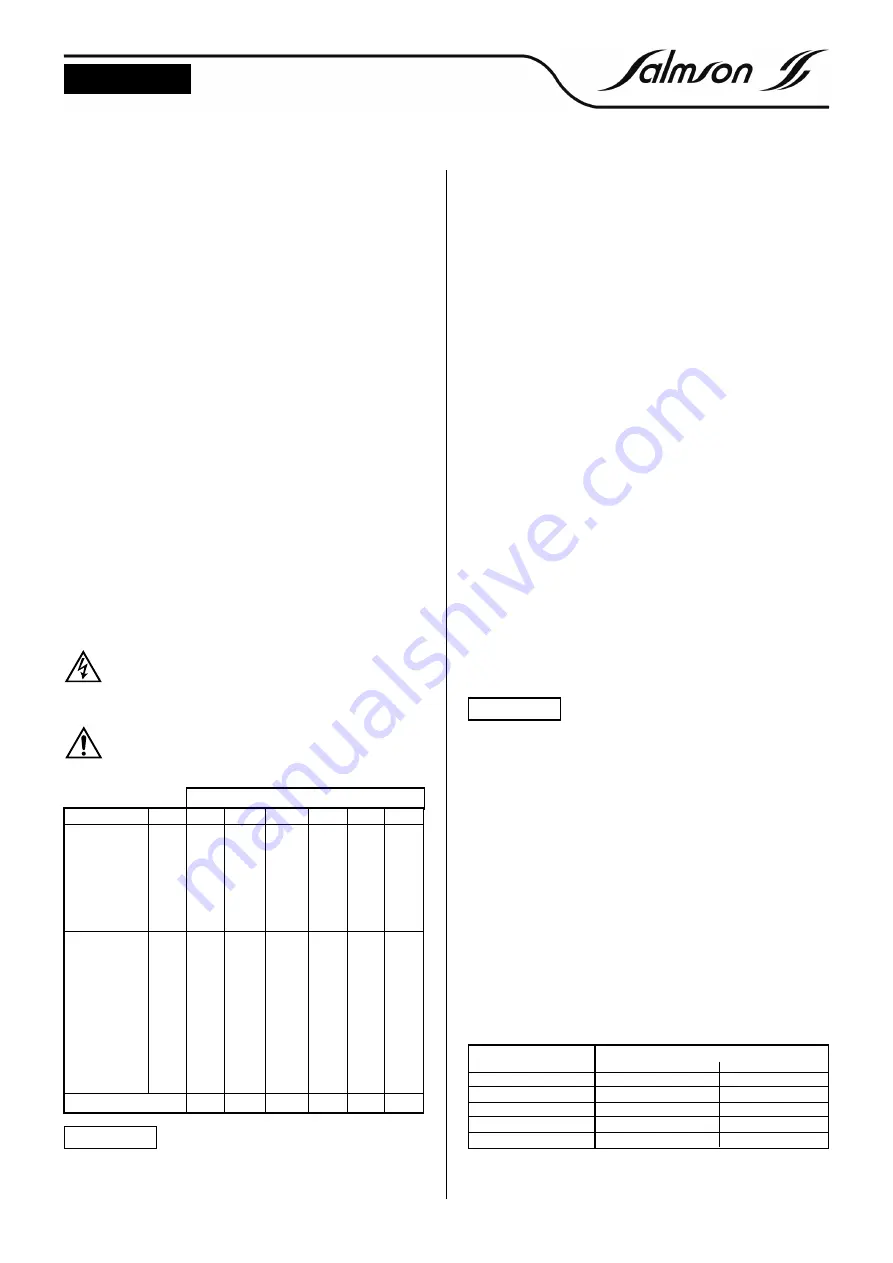

Maximum cable length (for direct start)

CABLE (mm

2

)

Motor

kW

1.5

2.5

4

6

10

16

0.25

100

•

•

•

•

•

0.37

85

144

•

•

•

•

230 V

0.55

64

107

140

•

•

•

1 - phase

0,75

49

83

110

165

•

•

50 Hz

1.1

32

54

80

120

195

•

1.5

25

35

60

95

153

245

2.2

17

25

45

65

102

163

0.37

570

•

•

•

•

•

0.55

380

610

•

•

•

•

0.75

282

470

740

•

•

•

1.1

204

340

540

•

•

•

400 V

1.5

156

260

420

530

•

•

3 - phase

2.2

102

170

290

400

600

•

50 Hz

3

79

132

230

320

490

•

3.7

70

125

200

290

420

680

4

58

97

180

250

380

560

5.5

45

75

140

200

300

500

7.5

30

50

100

145

210

350

Mass per meter (kg)

0.2

0.25

0.3

0.4

0.65

0.85

A failure of electric connection would damage

the motor.

- Do not forget the earth connection.

- A motor protection is required using a thermal or a magnetic cir-

cuit breaker (only for T4 or MD motor).

Motor connection :

a : black

b : blue

c : brown

d : green/yellow (

See FIG. 1-2-3

).

Single-phase motor type MP (

See FIG. 1

).

Single-phase motor type MD (

See FIG. 2

).

Three-phase motor type T4 (

See FIG. 3

).

6. STARTING UP

6.1. Sens de rotation

SINGLE-PHASE

:

No risk of inversion.

THREE-PHASE

:

To determine the right sense of rotation of the unit, check only the

delivery pressure, and bear in mind that the right sense of rotation

corresponds to the highest pressure.

Or by measuring the pressure, delivery valve closed and compare it

to the one required.

In case of reverse sense of rotation, interchange the two phase

wires inside the switch box or circuit breaker.

Nota

: The pressure measured at the borehole outlet with closed

valve corresponds to the head of the pump at zero output minus

the height between ground level and water level.

6.2. Running with closed valve

The pump must run only 2 minutes maximum with closed valve

because the water inside the pump overheats very quickly and

transmits this heat to the motor and can damage it.

6.3. Operation

Never run the pump dry even for a short time

period.

- Once again check all the electric connections, electric protec-

tion, rating of the fuse(s).

- Measure the current on each phase and compare with the nomi-

nal values mentioned on the nameplate.

- Do not exceed the nominal current of the motor.

- Measure the power supply voltage with motor running.

Allowed tolerance

: + 6 %, - 10 % in 50 Hz, ± 6 % in 60 Hz.

- Remove air from the delivery tube to avoid any hammerblow

effects when starting.

- if the motor-driven pump operates with an electronic starter or a

frequency converter, the starting and stop ramp time of the motor

must be set up at 3 seconds maximum.

Ambient temperatures :

Submersible motors are designed to run at nominal power at a

maximum water temperature of 30°C. The circulation speed along

the motor must be at least 8 cm/s for 4" motor to ensure an ade-

quate cooling.

When use at high water temperature, the load must be reduced in

proportion to the nominal current of the motor according to the

table hereafter.

Do not use motors in ambient temperatures exceeding 55°C.

The freezing point of the motor filling is -8°C.

CAUTION !

Water temperature

Maximum nominal current of the motor in %

From 0.37 to 5.5 Kw

Above 5.5 kW

35°C (95°F)

95 %

95

40°C (104°F)

95 %

88

45°C (113°F)

90 %

76

50°C (122°F)

80 %

62

55°C (130°F)

70 %

48

CAUTION !