06-2011

Page 19

Salford Farm Machinery Ltd.

2011 699-40' Disc Cultivator Assembly and Parts Manual

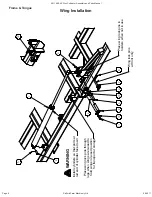

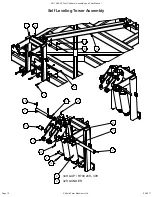

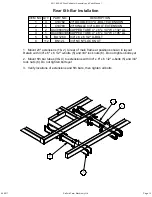

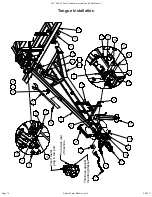

1. Line up axle tower (3) and upright of tandem axle assembly (1, 2) with lugs on main frame. Insert 1 1/2" x 13

7/8" flatbar pin (6) through tower and axle. Retain pin with 5/8" x 1 1/2" hex bolt (15) and 5/8" lockwasher (16).

Note orientation of lugs on axle towers.

2. Set mainframe turnbuckle (5) to 61" (155cm) long pin to pin. Place turnbuckle lock (25) over turnbuckle and

attach turnbuckle to frame with 1 1/4" x 5 1/2" pin (8), 1 1/4" machine bushings (18), and 5/16" x 2" cotter pins

(19). Attach turnbuckle to axle tower with 1 1/4" x 5 1/2" pin (8), 1 1/4" machine bushings (18), and 5/16" x 2"

cotter pins (10). Note: bushings go between plates and cotter pins.

3. Attach 4" bore x 8" stroke hydraulic cylinder (4) to axle tower and axle beam with 1" x 3 1/4" head pins (12)

and 1/4" x 1 1/2" cotter pins (21).

Connect hoses and charge lift axle cylinders with fluid following the

procedure in the axle lift hydraulics section of this manual before connecting rod ends of the cylinders

and the transport locks.

4. Attach transport lock (7) to axle tower with1" x 5" pin (11) and 5/16" x 1 1/2" cotter pins (20). Attach transport

lock to axle beam with 1" x 2 5/8" head pin (14) and 1/4" x 1 1/2" cotter pin (21). Insert 1" x 4 1/4" ring pin (9) into

tube on transport lock and retain with #9 hairpin (10).

5. Install 8000 lb hub and spindle assemblies (22) into axles and retain with 5/8" x 4 1/2" hex bolts (23) and 5/8"

locknuts (24).

6. Apply grease to all fittings.

Notice: Salford uses replaceable bushings (item 27 - 30). These are slightly oversized and need to be tapped

into place with a hammer. When removing worn bushings, take care not to gouge the seat surface.

Note: quantities shown are for complete main frame axle installation - both LH and RH.

ITEM QTY

PART NO.

DESCRIPTION

1

1

C00112L

14,000 LB TANDEM AXLE ASSEMBLY LH

2

1

C00112R

14,000 LB TANDEM AXLE ASSEMBLY RH

3

2

C10013

MAIN FRAME TOWER

4

2

HSR4008

4" BORE x 8" STROKE HYD. CYLINDER

5

2

A60031

2 1/2" TURNBUCKLE 50" TUBE

6

2

GPH2401312F 1 1/2" x 13 7/8" LG. AXLE PIN - HARDENED

7

2

C50010

TRANSPORT LOCK ASSEMBLY

8

4

GP2000512A05 1 1/4" x 5 1/2" PIN - 2 HOLES

9

2 GP1600414C04 1" x 4 1/4" RING & WASHER PIN

10 2

GHP9

#9 HAIR PIN

11 2

GP16005A05 PIN 1" DIA. x 5" LG. - 2 HOLES

12 2 GPHF1600314H04 1" x 3 1/4" SHOULDER PIN HARDENED W/FLATS

13 2

GP1600314H04 PIN 1" DIA. x 3 1/4" LG. WITH HEAD

14 2

GP1600258H04 PIN 1" DIA. x 2 5/8" LG. WITH HEAD

15 2

B1015

5/8 X 1 1/2" PLATED BOLT

16 2

BL10

5/8" LOCKWASHER

17 4

GM26

1" MACHINE BUSHING

18 8

GM30

1 1/4" MACHINE BUSHING

19 8

BSC0520

5/16" x 2" COTTER PIN

20 4

BSC0515

5/16" x 1 1/2" COTTER PIN

21 6

BSC0415

1/4" x 1 1/2" COTTER PIN

22 4

GW8000A

8000 lb GREASABLE HUB AND 14" SPINDLE ASSY

23 4

B1045

5/8 x 4-1/2" BOLT

24 4

BN10L

5/8" NYLOCK NUT NC

25 2

C10716

2 1/2" TURNBUCKLE LOCK

26 4

GBB125100075 1 1/4" x 1" x 3/4" LG. HARD BUSHING

27 4

GBB175150200 1 3/4" x 1 1/2" x 2" LG. HARD BUSHING

28 4

GBB175150062 1 3/4" x 1 1/2" x 5/8" LG. HARD BUSHING

29 4

GBB175150100 1 3/4" x 1 1/2" x 1" LG. HARD BUSHING

61"

(155cm) INITIAL SETTING

6

16

15

5

3

4

7

18

8

19

14

21

13

21

LH SHOWN, RH SIMILAR

Put pin (9) in tube for storage (working) position

Put pin (9) in hole for transport position

22

RH

1

Use this hole on rear

Use this hole on front

LH

27

28

29

26

Note: on 30ft 699 install LH axle on RH side of machine and RH axle on LH side of machine.

24

23

2

9

8

17

12

21

19

20

18

10

9

26

11

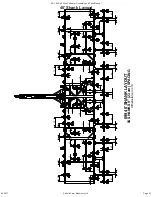

699 Main Frame Axle Installation