Controller functions

Page 40

UPT-606

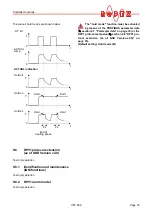

Invalid error messages may appear when the

controller is switched off owing to the unde-

fined operating state. This must be taken into

account when they are evaluated by the higher-

level controller (e.g. a PLC) in order to avoid false

alarms.

9.13

Error messages

In addition to the fault diagnosis which is coded in the

protocol, you can also access the PROFIBUS diagno-

stics function (extended controller diagnosis). The error

codes appear in the configuring tool in plain text,

because they are stored in the device master file.

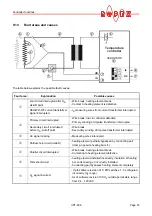

The table below shows how the analog voltage values

correspond with the faults that have occurred. It also

describes the fault and the required corrective action.

The error messages are listed in two separate tables for

controllers "up to software revision 015" and "as of soft-

ware revision 100". The block diagram in section 9.14

"Fault areas and causes" on page 45 permits each fault

to be cleared quickly and efficiently.

13 voltage levels for fault diagnostics appear at the

actual value output of all controllers as of software

revision 100. The error messages are differentiated

even more finely in the controller. The 3-digit error

codes described in brakets below can be displayed with

the ROPEX visualization software (

section 9.11

"Diagnostic interface/visualization software (as of soft-

ware revision 100)" on page 39) to facilitate trouble-

shooting.

If the actual value output is evaluated in order

to identify an error message - in the higher-

level controller, for instance - the tolerance window

must be adjusted to prevent it from being incor-

rectly interpreted. Please note the tolerances of the

actual value output (

section 5 "Technical data"

on page 8).

!

!