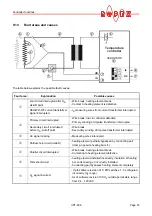

Controller functions

Page 30

UPT-606

9.7

Parameter data

The parameter data contains values for selecting the

heatsealing element alloy, the temperature range, the

upper and lower tolerance band limits for temperature

monitoring, the calibration temperature and the optional

heating time limit. It is transferred from the PROFIBUS

master to the UPT-606 each time the system is started

up. If the parameter data is changed during operation,

the UPT-606 performs a reset. The PROFIBUS com-

munication is not interrupted. The parameter data has

the following structure:

No.

Function

De-

fault

value

1

Possible

values

0…3 Reserved, set to 0

0

0

4

Temperature range /

alloy

10

0, 1, 4, 5, 8,

10

5

Lower temperature

OK threshold

10K

3…99K

6

Upper temperature

OK threshold

10K

3…99K

7

Calibration tempera-

ture

20°C

-1, 0…40°C

8

Heating time limit

(100ms units)

0

0…99

(0…9.9s)

9

Extended controller

dignostis

acti-

vated

deactivated,

activated

10

Measuring impulse

duration

17

17…30

(1.7…3.0ms)

11

Data format

High/

Low

byte

(Intel)

High/Low

byte (Intel),

Low/High

byte (Moto-

rola)

12

Correction factor Co

100%

25…200%

13/

14

Maximum

start temperature

100°

C

20…500°C

15

Error code format

4 bit

4 bit, 10 bit

16/

17

Temperature

cefficient

1700

ppm

400…4000

ppm

18

Temperature range

300°

C

200, 300,

400, 500°C

19/

20

Maximum

temperature

300°

C

200…500°

C

21

Temperature

diagnosis

de-

acti-

vated

deactivated,

activated

22/

23

Temperature dia-

gnosis delay time

(10ms steps)

0s

0…999

(0…9.99s)

24/

25

Heatup timeout

(10ms steps)

0s

0…999

(0…9.99s)

26

„TO“ bit

(Temperatur OK)

active

if

Tact

=

Tset

off,

active if

Tact=Tset,

active if

Tact=Tset

with latch

27

Hold mode

off

off,

on,

2s

1. The default value is stored in the device

master file and transferred from the PRO-

FIBUS master to the UPT-606 when the

system is started up.

No.

Function

De-

fault

value

1

Possible

values