Startup and operation

Page 20

UPT-606

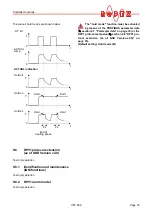

9. One of the following states then appears:

Up to software revision 015:

As of software revision 100:

10.Activate the AUTOCAL function while the heating

element is still cold by setting the "AC" bit

(

A

UTO

C

AL) in the PROFIBUS protocol

(

section 9.4 "PROFIBUS protocol" on page 23).

The yellow "AUTOCAL" LED lights up for the dura-

tion of the calibration process (approx. 10…15s).

The "AA" bit (

A

UTOCAL

a

ctive) is set in addition

and a voltage of app. 0V appears at the actual value

output (terminals 17+18). If an ATR-3 is connected,

it indicates 0…3°C (corresponds to app. 0 VDC).

When the zero point has been calibrated, the

"AUTOCAL" LED goes out and a voltage of app.

0.66VDC (300°C range) or 0.4VDC (500°C range)

appears at the actual value output instead. If an

ATR-3 is connected, it must be set to "Z".

If the zero point has not been calibrated suc-

cessfully, the "AL" bit (

al

arm active) is set and the

red "ALARM" LED blinks slowly (1Hz). In this case

the controller configuration is incorrect

(

section 8.2 "Controller configuration" on page 16

and ROPEX Application Report). Repeat the cali-

bration after the controller has been configured cor-

rectly.

11.When the zero point has been calibrated suc-

cessfully, specify a defined temperature by means

of the PROFIBUS protocol (set point) and set the

"ST" bit. The "RA" bit (controller active) is then acti-

vated and the "HEAT" LED lights up. The heating

and control process can be observed at the actual

value output:

The controller is functioning correctly if the tempera-

ture (which corresponds to the signal change at the

analog output or the actual value in the PROFIBUS

protocol) has a harmonious motion, in other words it

must not jump abruptly, fluctuate or deviate tempo-

rarily in the wrong direction. This kind of behavior

would indicate that the U

R

measuring wire have

been wired incorrectly.

If an error code is displayed, please proceed as

described in section 9.13 "Error messages" on

page 40.

12.The heatup process and the temperature control

must be optimized by means of setting the correc-

tion factor Co in the PROFIBUS parameter data

(GSD-file) or in the DPV1 protocol extension

(

section 9.7.10 "Correction factor Co" on

page 32) now. With this setting the manufacturing

process related tolerances of the heating element

are compensated..

"ALARM"

LED

"OUTPUT"

LED

ACTION

OFF

Short pulses

every 1.2s

Go to 10

BLINKS fast

(4Hz)

OFF

Go to 10

Lit conti-

nuously

OFF

Fault diagnosis

(

section 9.13)

"ALARM"

LED

"OUTPUT"

LED

ACTION

OFF

Short pulses

every 1.2s

Go to 10

BLINKS fast

(4Hz)

OFF

Go to 10

Lit conti-

nuously

OFF

Fault no. 901:

(Fault group: 7):

Supply voltage/

Sync-Signal mis-

sing

(

section. 9.2)

Otherwise:

Fault diagnosis

(

section. 9.13)

The controller is now ready