Controller functions

UPT-606

Page 27

5. AUTOCAL cannot be activated if error codes 1…3,

5…7 (As of software revision 100 also: 101…103,

201…203, 801, 9xx) occur at start-up. AUTOCAL

cannot be activated with error codes 5…7 (As of

software revision 100 also: 201…203, 801, 9xx) if

the controller has operated correctly, at least one

time, after start-up (

section 9.13 "Error mes-

sages" on page 40).

If the AUTOCAL function is disabled ("AG"

bit = 1) and if you attempt to activate it ("AC"

bit = 1) then the "AUTOCAL" LED blinks fast (4Hz).

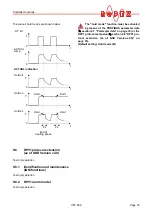

9.5.2

Start (ST)

When the "START" bit is activated ("ST" bit = 1), the

controller-internal set/actual comparison is enabled

and the heatsealing element is heated up to the SET

temperature. It remains at this temperature either until

the "ST" bit is reset or until the actual heating time

exceeds the preset heating time limit (

section 9.7.5

"Heating time limit" on page 31).

The "HEAT" LED on the front panel of the UPT-606

lights up continuously for the duration of the heating

phase.

A start request is not processed if the AUTOCAL func-

tion is active, the controller has reported an alarm, the

set point is less than 20°C higher than the calibration

temperature or the "RS" bit is set. In all these cases the

"HEAT" LED blinks.

The heating process is terminated if the "ST" bit is reset

or if a PROFIBUS fault occurs.

The "ST" bit is only accepted if the AUTOCAL

function is deactivated and there are no

alarms.

The alarm relay is switched if the "ST" bit is activated

while a warning message is indicating error codes

8...12 (as of February 2006 also: 104…106, 111…114,

211, 302 oder 303) (

section 9.13 "Error messages"

on page 40). The heatsealing element is no longer

heated up.

9.5.3

Reset (RS)

This bit resets the controller if the controller reports an

alarm.

No AUTOCAL or START requests are accepted as

long as the "RS" bit is set. From then on, only fault nos.

5 and 7 (As of software revision 100:

201…203, 901, 913) are evaluated and output by the

fault diagnosis function. The power section is not acti-

vated in this state and no measuring impulses are

generated. Consequently, the actual value is no longer

updated. The reset request is not processed until the

"RS" bit is reset. The PROFIBUS communication is not

interrupted by a controller reset. The controller simply

requests the parameter data from the PROFIBUS

master again.

As of software revision 100, the controller actual value

output changes to 0…3°C (i.e. approximately 0VDC)

while the "RS" bit is being activated. This may be inter-

preted by the higher-level controller (e.g. a PLC) as

feedback.

The "AUTOCAL" function is not aborted if the "RS" bit

is activated while it is still executing.

The controller performs an internal initializa-

tion run lasting approximately 500ms after

the "RESET" signal is deactivated. The next

heatsealing process cannot be started until it has

finished.

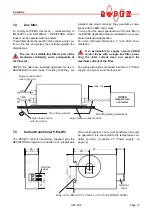

If a contactor Kb is used to deactivate the

control loop

(

section 7.3 "Power supply"

on page 12

),

it must be energized again 50ms at the

latest after the "RESET" signal is deactivated. If it is

energized too late, an error message will be output

by the controller.

9.5.4

Measurement pause (MP)

No more measuring impulses are generated by the

controller as soon as the "MP" bit is set. From then on,

only fault nos. 5 and 7 (As of software revision 100:

201…203, 901, 913) are evaluated and output by the

fault diagnosis function. In addition, the actual value is

no longer updated. The last valid value before the bit

was set is output. As soon as the bit is reset, new

measuring impulses are generated, all error messages

are evaluated and the actual value is updated again.

This bit is only active in measuring mode. "ST", "RS"

and "AC" take priority. The bit is suitable for all applica-

tions in which the electrical connections of the heatse-

aling element need to be disconnected during normal

operation without triggering an alarm (e.g. sliding rail

contacts).

!

!

!

!