12

MAINTENANCE

Regular maintenance insures trouble-free operation. Your new compressor represents the finest engineering and construction available. However, even

the finest machinery requires periodic maintenance. A good maintenance program will add years of service to your air compressor. The following is recommended as

a minimum maintenance program. For your protection, disconnect power supply after each day’s operation and drain air from system before performing any

maintenance.

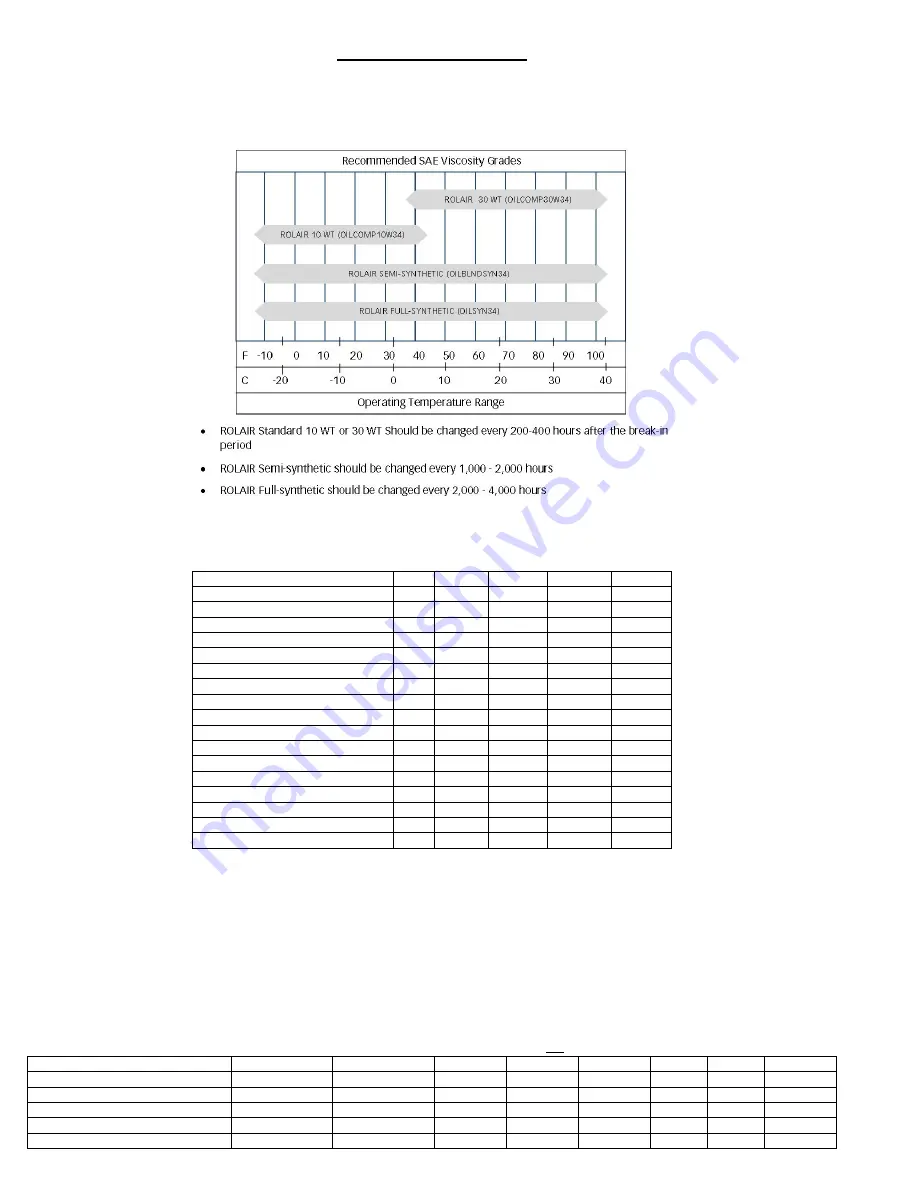

OIL TABLE

For maximum performance and service life, we recommend using ROLAIR Premium Quality compressor oil.

MAINTENANCE SCHEDULE

Recommendation

Daily Weekly Monthly Quarterly Annually

Check Oil Level

X

Drain Moisture from Tank(s)

X

Inspect Air Filter(s)

X

Check for Unusual Noise or Vibration

X

Inspect Belt Guard

X

Check for Air or Oil Leaks

X

Clean Exterior of Air Compressor

X

Check Condition of Vibration Pads

X

Tighten/Retorque Bolts

X

Check Belt Tension

X

Check Operation of Safety Valve

X

Change Compressor Oil

X

Clean/Change Air Filter

X

Perform Pump Up Time Test

X

Check Operation of System Controls

X

Check Air Tanks for Dents/Leaks

X

Tank Inspection by Certified Inspector

X

*Check and re-torque (see chart on pg. 12) only after pump has completely cooled to room temperature.

**Always make sure crankcase vent (breather) is free and unobstructed when changing or checking oil.

MAINTENANCE HINTS:

1) Use a soap/water solution to check for air leaks.

2) Never clean filters with a flammable solvent.

3) Re-torque head bolts only after pump has cooled.

4) Move motor 1/4" and roll belts back on to increase belt tension on electric units.

5) Never weld on air tank(s).

6) Use heat to loosen Loctite seal on drain valves, engine pulleys and flywheels before attempting to remove.

TORQUE CHART (INCH/LB

)

Determine pump type using suffix of model number (Example: V5180K30 uses a K30 pump.)

Pump Type

K17/K18

K24/K25

K28

K30

K35

K50

K60

K100

Head Bolts

243

243

347

347

347

694

347

694

Cylinder Bolts

182

182

330

330

330

521

330

521

Bearing Carrier Bolts

130

130

130

130

130

165

165

165

Connecting Rod Bolts

121.5

121.5

121.5

173.6

173.6

217

217

199.7

Flywheel Nut (left-hand thread)

382

382

477

477

477

607

607

694