10

OPERATION

LUBRICATION:

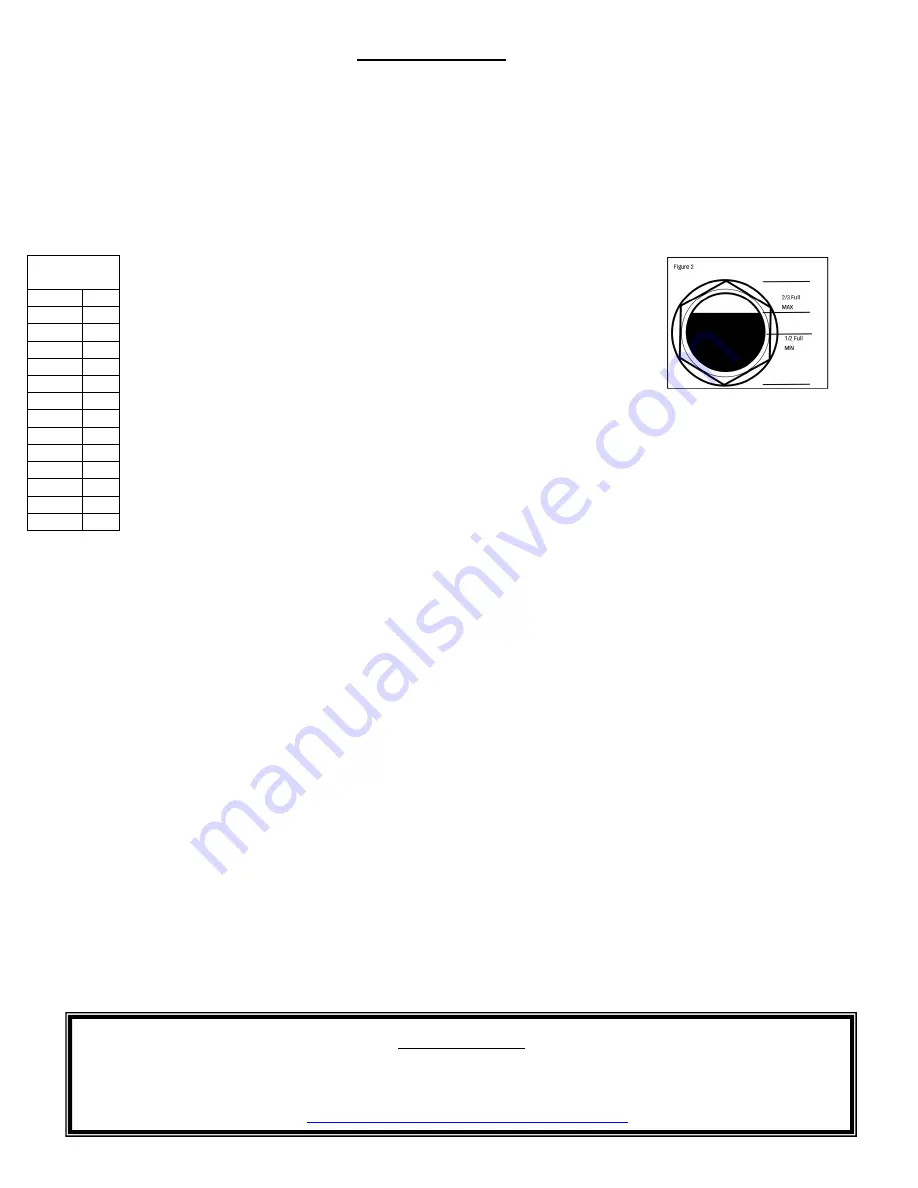

Prior to daily operation, make a habit of checking the oil level in your compressor pump. A sight gauge on the outside of the

pump’s crankcase is provided to make the job easier. Always maintain the oil level to read 2/3 full on the sight gauge. Oil levels over

this amount will result in oil blowing past the rings or out of the crankcase breather. Lower amounts of oil will result in insufficient

lubrication of moving parts.

Reciprocating compressors will consume a certain amount of oil under normal operation. If you are concerned about your

oil consumption, monitor and record oil consumption daily and consult your local dealer. When filling your crankcase with oil, be

sure to use a single viscosity, non-detergent oil.

DO NOT USE A DETERGENT OIL!!

Check the oil before starting.

Prior to shipping, complete units are filled with oil and tested. The oil should be

drained and replaced after an initial break-in period of 50 hours.

NOTE:

Bare pumps are shipped without oil. See reference charts for oil type and

capacity.

Whether you have purchased a complete unit or bare pump, check the oil level and correct if needed before

starting each day.

Important:

Do not over-fill your pump. It will cause harm.

After break-in period, use a single-grade, non-detergent motor oil with foam, rust and oxidation inhibitors. For

maximum performance and service life, we recommend using ROLAIR Premium Quality compressor oil. (See your

oil distributor or representative for compressor oil.)

DO NOT USE DETERGENT OIL!

See chart for oil recommendation in varying temperature conditions.

WET CONDITIONS:

Do not operate your compressor in damp or wet conditions, or after it has been exposed to rain/sleet/ice/snow or moisture of

any kind. Failure to follow this warning could lead to electric shock and/or rust and ice forming on critical components, making the compressor

dangerous to operate. Always operate and/or store compressor in a clean, dry location with good ventilation.

FREEZING TEMPERATURES:

Proper fluid maintenance and warm up procedures are mandatory before attempting to start or operate an air compressor in freezing

temperatures. Water, a natural byproduct of compressed air, could turn into ice and potentially block air flow into, though, and/or out of the

pump, air tank(s), and air line(s). Drain air tanks/ lines after every use and leave drain valves open when not in use.

If all, or part, of the compressor may be frozen, you must completely thaw the compressor before attempting to start. Gradually increase the

temperature above freezing and then drain moisture from the air tanks, intercoolers, and water traps.

Cold Weather Best Practices:

•

Do not attempt to start a frozen compressor. Thaw completely first.

•

Store your air compressor in a clean, dry area that stays consistently above freezing temperatures.

•

Change the oil in the pump and engine to winter grade (check owner’s manual).

•

Prior to starting, open the tank drain(s) and allow the compressor to run for 45-60 seconds with the tank drain(s) open before closing

to build tank pressure.

•

Using a lubricator with de-icing fluid may also be needed to keep your air lines from freezing up/blocked by ice.

•

Contact your ROLAIR dealer or our factory customer service department if you have additional questions.

Oil Capacity

(oz.)

BK119 45

K17

34

K18

34

K24

61

K28

61

K30

47

K35

47

K50

59

K60

98

K100

127

MK103 17

MK113 30

PT03

24

PV02

24

Proper Oil Level:

IMPORTANT

Periodic inspection of in-service pressure-retaining items is mandated in your jurisdiction. In addition to performing

these inspections, your jurisdiction may require or permit insurance companies to provide the mandated inspection

service for their insured. Information for your jurisdiction can be found on the National Board of Boiler and Pressure

Vessel Inspectors website by typing