8

INSTALLATION & PIPING

LOCATION:

•

Locate the compressor in a cool, dry, clean and well-ventilated area with a temperature range between 35° and 105°F.

WARNING!

Under no

circumstances should the air compressor be installed in an area that may be exposed to a dirty, corrosive atmosphere, toxic vapors or volatile

fumes. Do not store toxic, volatile or corrosive agents near the compressor.

•

The intake filter may be remotely located. Enlarge size of intake piping by 1/4” in size for each 10 feet of length.

•

Install so that the flywheel/belt guard is at least 18” from an adjacent wall. Allow space on all sides for air circulation and ease of

maintenance.

•

Make sure the compressor tank is mounted level on a solid foundation using vibration dampening pads made of felt/rubber. If vibration pads

cannot be located, the skid on which the compressor is shipped may be left on and used as a mounting base. Solid shims may be used to level

unit before bolting or lagging unit to prevent movement.

NOTE:

Contact your local ROLAIR representative for information on level-rite mounting pads or if excessive vibration or movement is noticed

upon initial test run. When hard-mounting a gas-powered air compressor on a trailer or a truck bed, leave one of the four mounting bolts looser

than the others (slightly beyond hand-tight) to help minimize vibration and improve the overall performance and life of the unit.

PIPING FIT-UP:

Always position air compressor to avoid an excessive amount of tension between the external air lines and connection at the air tank. The

piping should be lined up without having to spring or twist it into position. Adequate expansion loops or bends should be installed to prevent

undue stresses at the compressor resulting from the changes between hot and cold conditions. Pipe supports should be mounted independently of

the compressor and anchored as necessary to limit vibration and prevent expansion strains.

*Never join pipes or fittings with lead-tin soldering. Welded or threaded steel pipes and cast-iron fittings, designed for the pressures and

temperatures, are recommended. Never use PVC or plastic pipe.

Pipe sizes for compressed air lines

Air

CFM

Length of Pipe Lines in Feet

25

50

75

100

150

200

250

300

1-5

1/2

1/2

1/2

1/2

1/2

1/2

1/2

1/2

10

1/2

1/2

1/2

3/4

3/4

3/4

3/4

3/4

15

1/2

3/4

3/4

3/4

3/4

3/4

3/4

3/4

25

3/4

3/4

3/4

3/4

3/4

1

1

1

30

3/4

3/4

3/4

3/4

1

1

1

1

35

3/4

3/4

1

1

1

1

1

1

40

3/4

1

1

1

1

1

1

1

60-70

1

1

1

1

1-1/4 1-1/4 1-1/4 1-1/4

80-100 1-1/4 1-1/4 1-1/4 1-1/4 1-1/2 1-1/2 1-1/2 1-1/2

Check all piping and fittings regularly to avoid leaks in the system.

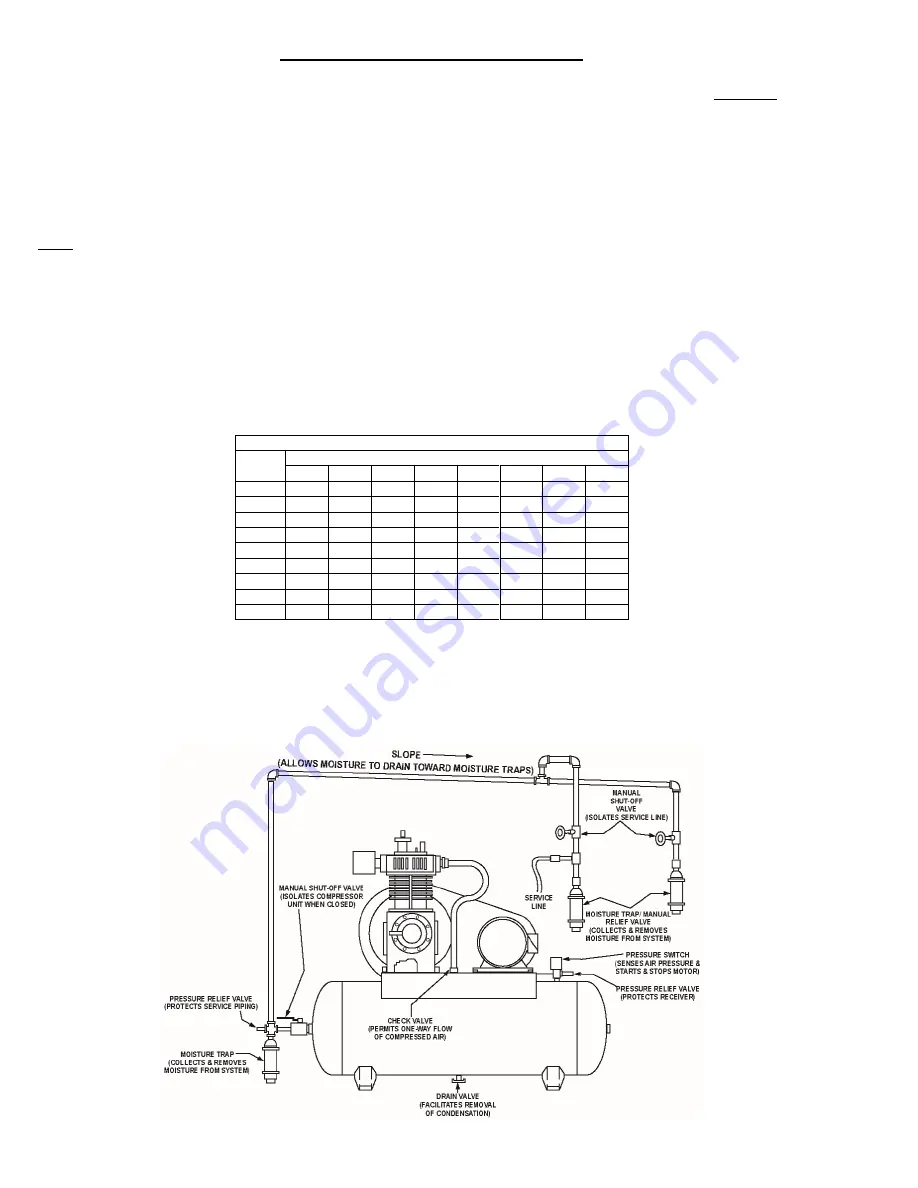

PIPING:

The compressed air distribution system should be of sufficient pipe size to keep the pressure drop between the supply and point of use to

a minimum. All piping should be sloped to an accessible drain-point. Outlets should be taken from top of mainline so that moisture will not enter

the outlet.