32

IQ9500 Installation Manual

8.0

RS-232 Specification

8.1

RS-232 Ports

The IQ9500 is equipped with three RS-232 ports for

connecting devices such as a force balance, bar code

laser/pen scanner, PC, or printer (bar code, tape, or

ticket). SPEC 0 (bit 1), SPEC 3, and SPEC 8 through

SPEC 15 are used when connecting peripheral

devices.

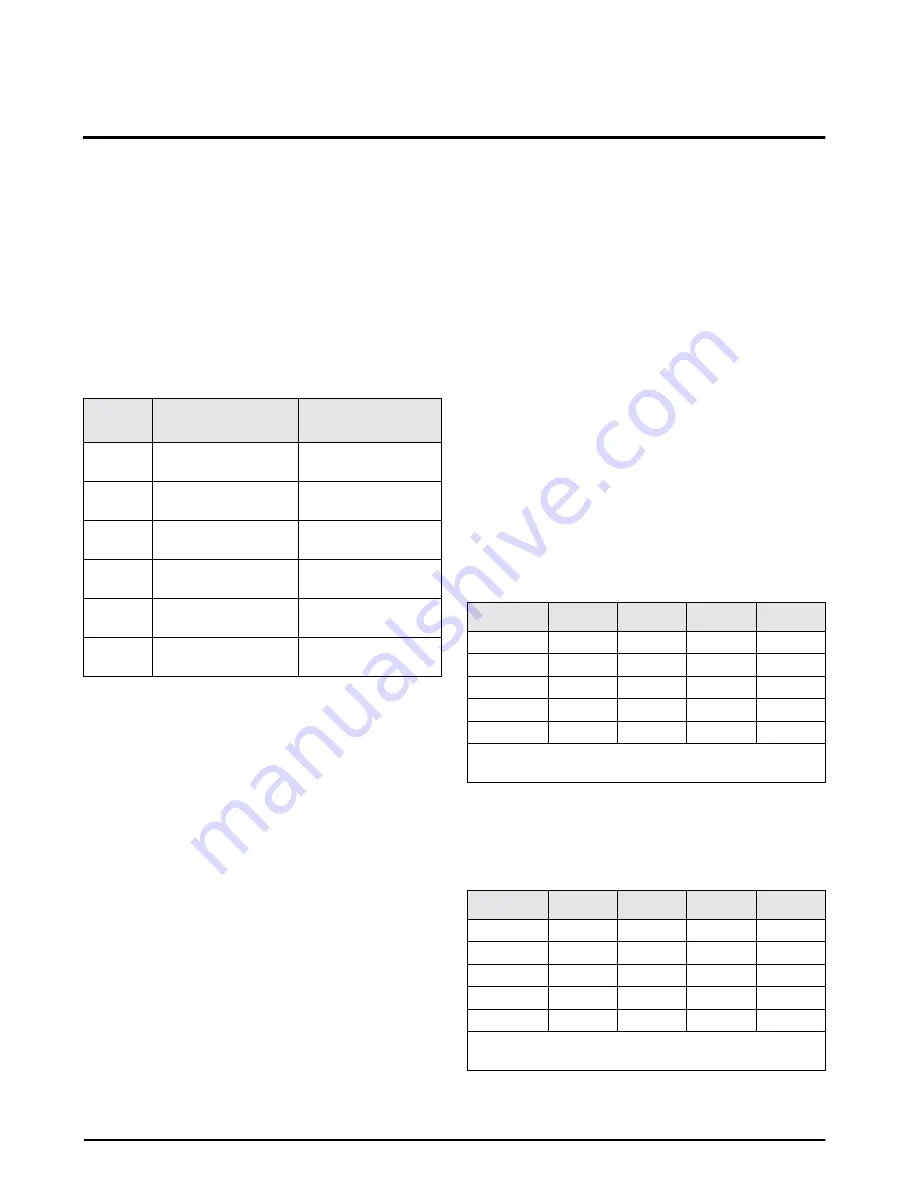

SPEC 13, bits 2, 1, and 0 determine which devices are

connected to the 9-pin D-Sub connector and 8-pin

DIN Connector 2. Table 8-1 shows the specification

bit number and the corresponding eight- and nine-pin

connector designation.

SPEC 8 through SPEC 11 are used to configure the

baud rate, data length, parity, and stop bits for each

device installed in the system. As shown in Table 8-1,

SPEC 8 and SPEC 9 are always configured with a

force balance while SPEC 10 and SPEC 11 are

configured with a printer. Therefore, if a PC is

connected in place of either the force balance or

printer, those specifications that follow the force

balance or printer are now used for the PC.

For example, if you wanted to connect a PC on the

9-pin D-Sub connector and a TM-U200 printer to the

8-pin DIN connector, SPEC 13 (bits 2, 1, and 0)

would be configured to 011. If the RS-232 settings for

the PC are 9600 baud rate, eight-bit data length, no

parity and one stop bit, SPEC 8 would be configured

to 0111 and SPEC 9 would be configured to 0100. If

the RS-232 settings for the printer are 4800 baud rate,

seven-bit data length, even parity and one stop bit,

SPEC 10 would be configured to 1010 and SPEC 11

would be configured to 0011. SPEC 3 would need to

be configured to 0011 or 0010.

NOTE:

See Section 9.0 for remote platform wire numbering

and connector pinout information.

8.2

Eltron Printers

Refer to the Eltron printer manual for baud rate, data

bit, and stop bit settings if it desired to change them

from the factory defaults. The default settings are

9600 baud rate, eight-bit data length, no parity and

one stop bit.

NOTES:

• The IQ9500 downloads some label formats to the

printer during power up. Eltron printers must be

connected to the IQ9500 and powered on

before

powering up the IQ9500.

• Eltron 2722 printer software must be Version 4.00 or

higher. Eltron 2742 printer software must be Version

4.02 or higher.

Table 8-2 contains the Eltron bar code label printer

specification settings configured for 9600 baud rate,

eight data bits, no parity, one stop bit, and connected

to the 9-pin D-sub connector.

Table 8-3 contains the Eltron bar code label printer

specification settings configured for 9600 baud rate,

eight data bits, no parity, one stop bit, and connected

to the 8-pin DIN connector.

SPEC 13,

Bits 2, 1, 0 9-Pin D-Sub Connector

8-Pin DIN Connector

000

Printer

SPEC 10 and 11

Force balance

SPEC 8 and 9

001

Force balance

SPEC 8 and 9

Printer

SPEC 10 and 11

100

PC

SPEC 10 and 11

Force balance

SPEC 8 and 9

101

Force balance

SPEC 8 and 9

PC

SPEC 10 and 11

010

Printer

SPEC 10 and 11

PC

SPEC 8 and 9

011

PC

SPEC 8 and 9

Printer

SPEC 10 and 11

Table 8-1. SPEC 13 Configuration with Eight- and Nine-Pin

Connector Designation

Specification

Bit 3

Bit 2

Bit 1

Bit 0

SPEC 3

0

0

0

0

SPEC 10

1

1

1

1

SPEC 11

0

0

0

0

SPEC 13

0

0

0

0

SPEC 21

see below

—

—

—

SPEC 21: For Eltron 2722 printers, set SPEC 21, bit 3 to 0;

for 2742 and 2600 Series printers, set bit 3 to 1.

Table 8-2. Eltron Printer Setup for 9-Pin D-Sub Connector

Specification

Bit 3

Bit 2

Bit 1

Bit 0

SPEC 3

0

0

0

0

SPEC 10

1

1

1

1

SPEC 11

0

0

0

0

SPEC 13

0

0

0

1

SPEC 21

see below

—

—

—

SPEC 21: For Eltron 2722 printers, set SPEC 21, bit 3 to 0;

for 2742 and 2600 Series printers, set bit 3 to 1.

Table 8-3. Eltron Printer Setup for 8-Pin DIN Connector