Description of function

19

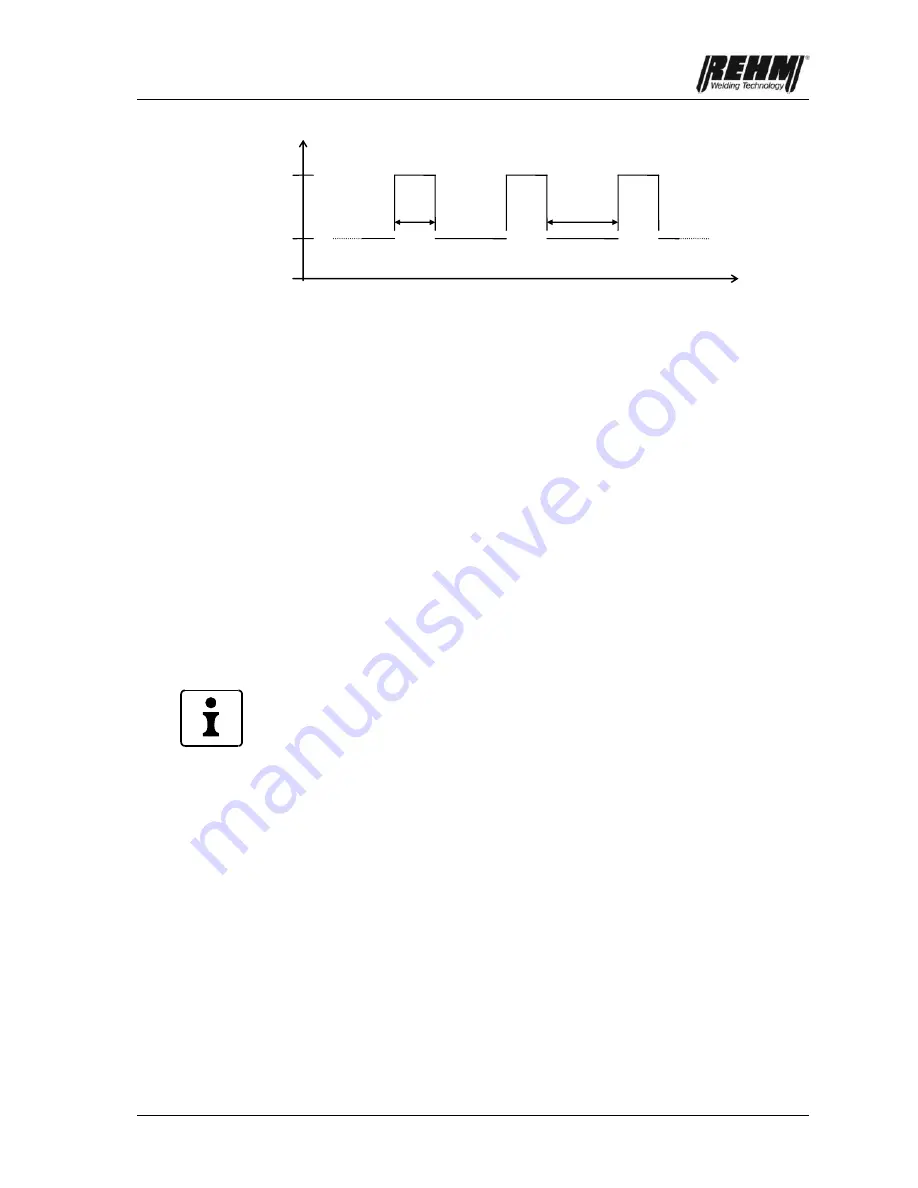

Fig 3.3: Welding current during pulsed welding

If a twin-button torch is used, pulsing can be switched off and also back on during

welding by pressing torch button 2. If torch button 2 is pressed while the welding

current is pulsing, pulsing is switched off and welding is continued using welding

current I2. This can for example be used to ensure that the lower welding current

I2 is used until a new filler metal is provided and welding is continued with

pulsing welding current by again pressing the torch button 2.

Conventional pulsing: Pulsing with pulse times greater than 0,1 second

The settings of the peak current time (t1) and the background current (t2) times

determine the time in which the peak current (I1) and the background current (I2)

is switched on and off. The digital display instrument always shows the currently

emitted welding current.

The welding current and the time for each pulse should be such that the

workpiece melts during the peak current phase and then is allowed to cool down

during the background current phase. Pulsed TIG welding allows the operator to

have better control of the welding pool under difficult conditions. Particularly

when for example, when welding out of position, bridging gaps, and welding thin

materials.

Note: If a twin button torch is being used, and button 2 is depressed during

pulsing, the pulsing will be switched off and the welding will continue with the

welding current setting I2. Depressing torch button 1 restores the pulsing process

once again.

High frequency pulsing: with a pulse frequency of 50 Hz up to 500 Hz

The welding current values set for the current I1 and I2 determine the pulse

amplitude. The active time for duration of these current settings is equal. With HF

pulsing switching from one current level to another occurs very quickly, hence the

name high frequency pulsing.

In order to calculate the pulse frequency, the following relationship exists

between the pulse timing t1 and t2:

Total pulse time = I1-Pulse time + I2-Pulse time = 1 / Pulse frequency

I1-Pulse time

= I2-Pulse time

= 0,5 * Total / Pulse time

Example:

Pulse frequency = 50 Hz

Total Pulse time = I1-Pulse time + I2-Pulse time = 1 / 50 Hz = 20 ms = 0,02 s

I1-Pulse time = 0,5 * Total Pulse time = 0,01s

I2-Pulse time = 0,5 * Total Pulse time = 0,01s

This means that the welding current has the value set for I1 for 0,01 s (=10 ms)

and that the welding current has the value set for I2 for 0,01 s (=10 ms), the

switching from once current to the other continues ad. Infinitum.

Current I1

Current I2

Pulse time I1

Pulse time I2

Time

0

Содержание 150 3310

Страница 1: ...GB OPERATING INSTRUCTIONS TIG welding units TIGER 170 210 DC AC DC SET...

Страница 7: ...Introduction 7 1 2 General description Fig 1 1 TIGER 170 DC and Tiger 210 AC DC...

Страница 57: ...Spare parts 57 10 2 Machine components photographs 2...

Страница 58: ...Spare parts 58...

Страница 63: ......