UM-1096

Revision A

36

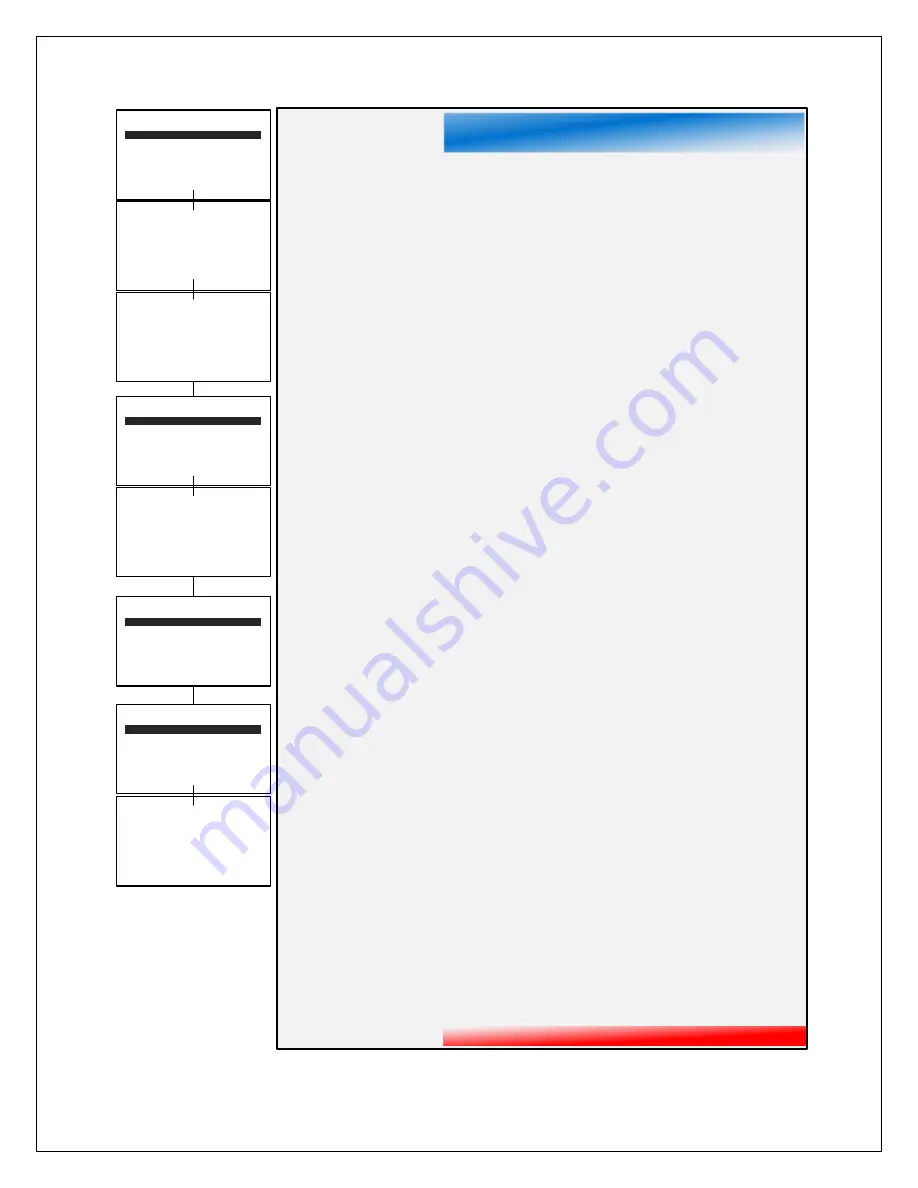

Dat a Fr om

Sour ce Sensor

Remot e Sensor No

Mi n Raw 800

Max Raw 4000

Remot e I D 1

Al i as 31001

Dat a Fr om

I nt er f ace COM1

Fi l t er ( second) 5

Byt e Or der ABCD

Pol ar i t y Negat i ve

Heat er Enabl ed No

Heat ( degC) 25

Dat a Fr om

Set Vol t age >

Set Bal ance >

Set PGA >

Mar ker >

Conf i gur e

Tag Measur ement Name

E. Uni t s E. Uni t s

Zer o 0

Span 100

Deci mal Poi nt s 0

Conf i gur e

War mup( m) 1

Cal i br at i on

Zer oSet poi nt 0

SpanSet poi nt 50

Temp Comp

- 40C g1. 000: o+0. 000

- 30C g1. 000: o+0. 000

- 20C

g1. 000: o+0. 000

- 10C

g1. 000: o+0. 000

0C

g1. 000: o+0. 000

10C

g1. 000: o+0. 000

Temp Comp

20C

g1. 000: o+0. 000

30C

g1. 000: o+0. 000

40C

g1. 000: o+0. 000

50C

g1. 000: o+0. 000

60C

g1. 000: o+0. 000

Cal Gai n 1

Gai n Of f set 0

Set Uni t y >

Cal i br at e >

Deadband ( %) 1

Bl ock Negat i ve Yes

Cal Pur ge( m) 1

Input Settings Menus (cont’d)

Data From (certain menu items only show up depending on the input type)

o

Source

determines the type of sensor installed in the detector. E.g. bridge,

electrochemical, etc.

o

Remote Sensor

set to Yes indicates that the sensor is installed remotely with Remote

sensor option.

o

Min and Max Raw

set the range of the input to the A/D converter. Normally set to

800/4000. Useful when the sensor’s output doesn’t provide a full range signal.

o

Remote ID

is where the Modbus slave’s ID number is entered

o

Alias

is the register number which defines the location of the variable representing the

input value of the Modbus data received through the communication ports

o

Interface

assigns which communication port the Modbus slave is connected to and the

detector will get its data from

o

Filter (second)

sets the number of seconds over which samples are averaged

o

Byte Order

determines WORD and BYTE alignment of data at the remote Modbus

transmitter when sending this 4-byte IEEE floating point values

o

Polarity

determines the polarity of the sensor

o

Heater

Enabled

determines if the sensor heater is turned on or off

o

Heat (degC)

is the thermostat setting of the sensor

o

Set

Voltage

set’s the voltage being supplied to bridge type sensors

o

Set

Balance

adjusts the balance of a catalytic bead sensor and must only be adjusted

with ZERO gas on the sensor.

o

Set

PGA

is the adjustment that matches the input signal range to the detectors input

signal conditioning circuits.

o

Marker

used to detect special modes of operation from analog inputs, which some

monitors use to indicate special modes of operation, such as calibration mode

Configure

o

Tag

is a 16-character ASCII field typically used to describe the monitored point by user

tag number or other familiar terminology.

o

E. Units

or engineering units may have up to 10 ASCII characters, and is usually factory

configured based on sensor type.

o

Zero

defines the reading to be displayed when the output is 4mA (0%)

o

Span

defines the reading to be displayed when 20mA (100%) is the output.

o

Decimal Points

sets the resolution of the displayed reading, and may best to zero, one

or two.

o

Block Negative

blocks negative values from being display (Displays 0).

o

Deadband (%)

allows forcing low values to continue to read zero. This is useful when

there are small amounts of background gases that cause fluctuating readouts above

zero. The highest amount of Deadband allowed is 5%. Note: Deadband affects all

outputs as well as the local reading.

o

Warmup (m)

defines the time allotted for sensor warmup. During this time output s will

be held at a zero value and relays will stay in their normal state.

o

Cal Purge (m)

determines the amount of time the transmitter will stay in calibration

mode after calibration is complete as the sensor returns to normal state.

Calibration

o

Zero Setpoint

is set to the zero value.

o

Span Setpoint

is set to the calibration gas value, typically 50% of full scale.

o

Cal Gain

reflects the change made when calibrating.

o

Gain Offset

reflects the change made when calibrating.

o

Gain Unity

is to reset the Gain and Offset back to default (1 and 0 respectively)

o

Calibrate

is used to calibrate sensors.

Temp Comp

allows the user to adjust the gain and offset that is applied to sensors to

compensate for temperature drift. Factory supplied sensors are preprogrammed with

these values which are automatically uploaded from the Smart Sensor.

Содержание 10-0517

Страница 4: ...UM 1096 Revision A III Drawings 44...

Страница 10: ...UM 1096 Revision A 5 Figure 2 Remote Sensor Enclosure Mounting Dimensions...

Страница 26: ......

Страница 49: ...UM 1096 Revision A 44 Appendix 9 Drawings Drawings Figure 13 Mounting Dimensions...

Страница 50: ...UM 1096 Revision A 45 Figure 14 10 0517 CPU Board Figure 15 10 0533 I O Board...

Страница 51: ...UM 1096 Revision A 46 Figure 16 10 0532 Modbus Relay Board...