LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 13

f) After it has been determined that each appliance

remaining connected to the common venting system

properly vents when tested as outlined above, return

doors, windows, exhaust fans, fi replace dampers

and any other gas-burning appliance to their

previous condition of use.

Une fois qu'il a été d éterminé, selon la métode

indiquée ci-dessus, que chaque appareil raccordé

au système d'évacuation est mis à l'air libre de façor

adéquate. Remettre les portes et les fenêtres, les

ventilateurs, les registres de cheminées et les

appareils au gaz à leur position originale.

g) Any improper operation of the common venting

system should be corrected so the installation

conforms with the National Fuel Gas Code, ANSI

Z223.1/NFPA 54. When resizing any portion of the

common venting system, the common venting

system should be resized to approach the minimum

size as determined using the appropriate tables in

Appendix F in the National Fuel Gas Code, ANSI

Z223.1/NFPA 54 and or CAN/CGA-B149 Installation

Codes.

Tout mauvais fonctionnement du systéme d'évacu-

tion commun devrait étré corrigé de façor que

l'installation soit conforme au National Fue Gas

Code, ANSI Z223.1/NFPA 54 et (ou) aux codes

d'installation CAN/CGA-B149. Si la grosseur d'une

section du système d' évacuation doit étré modifi ée,

le système devrait étré modifi é pour respecter les

valeurs minimales des tableaux pertinents de

l'appendice F du National Fuel Gas Code, ANSI

Z223.1/ NFPA 54 et (ou) des codes d'installation

CAN/CGA-B149.

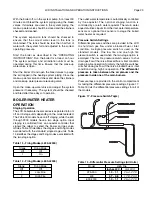

GENERAL PIPING REQUIREMENTS

CAUTION: Improper piping of this boiler/water heater

will void the manufacturer's warranty and can cause

boiler failure resulting in fl ooding and extensive

property damage! Excessive water hardness causing

scaling in the copper heat exchanger tubes is

NOT

covered under the manufacturer’s warranty.

Excessive pitting and erosion of the internal surface

of the copper heat exchanger tubes is

NOT

covered

under the manufacturer’s warranty if the result of

high water fl ow rates, see Table 7. Return water

temperatures below 125°F,

52°C

will result in heat

exchanger damage from excessive condensation

voiding the manufacturer’s warranty, see Primary/

Secondary Piping Figure 11.

NOTE: Shut off valves and unions should be

installed at the inlet and outlet connections of the

boiler/water heater to provide for isolation of the unit

should servicing be necessary.

Table 7 - Temperature Rise Table

Δ

T = 15 °F

Δ

T = 8.3 °C

Model

Flow

Rate

Pres.

Drop

Flow Rate

Pres. Drop

Number

GPM

Ft

L/s kPa

225

24.6 0.18

1.6 0.5

300

32.8 0.31

2.1 0.9

400

43.7 0.70

2.8 2.1

600

65.6 1.84

4.1 5.4

750

82.0 3.32

5.2 9.8

Δ

T = 20 °F

Δ

T = 11.1 °C

Model

Flow Rate Pres. Drop

Flow Rate Pres. Drop

Number

GPM

Ft

L/s

kPa

300

24.6 0.18

1.6 0.5

400

32.8 0.41

2.1 1.2

600

49.2 1.08

3.1 3.2

750

61.5 1.95

3.9 5.7

1050

86.1 5.16

5.4 15.2

1200

98.4* 8.14

6.2 24.0

1480

121.4* 7.94

7.7 23.4

Δ

T = 25 °F

Δ

T = 13.9 °C

Model

Flow Rate Pres. Drop

Flow Rate Pres. Drop

Number

GPM

Ft

L/s kPa

400

26.2 0.27

1.7 0.8

600

39.4 0.71

2.5 2.1

750

49.2 1.29

3.1 3.8

1050

68.9 3.41

4.3 10.1

1200

78.7 5.38

5.0 15.9

1480

97.1 5.25

6.1 15.5

1650

108.2 7.02

6.8 20.7

Δ

T = 30 °F

Δ

T = 16.7 °C

Model

Flow

Rate

Pres.

Drop

Flow Rate

Pres. Drop

Number

GPM

Ft

L/s kPa

600

32.8 0.51

2.1 1.5

750

41.0 0.92

2.6 2.7

1050

57.4 2.44

3.6 7.2

1200

65.6 3.84

4.1 11.3

1480

80.9 3.75

5.1 11.0

1650

90.2 5.01

5.7 14.8

1970

107.7 8.75

6.8 25.8

2300

125.7* 12.45

7.9 36.7

Δ

T = 35 °F

Δ

T = 19.4 °C

Model

Flow

Rate

Pres.

Drop

Flow Rate

Pres. Drop

Number

GPM

Ft

L/s kPa

600

28.1 0.38

1.8 1.1

750

35.1 0.69

2.2 2.0

1050

49.2 1.83

3.1 5.4

1200

56.2 2.89

3.5 8.5

1480

69.3 2.82

4.4 8.3

1650

77.3 3.77

4.9 11.1

1970

92.3 6.58

5.8 19.4

2300

107.8 9.36

6.8 27.6

*Flow exceeds recommended maximum use a greater temperature

rise or consult manufacturer. Cupro-Nickel exchanger should be

considered.