LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 15

CAUTION: A temperature rise outside of the range

listed in Table 7 indicates that the fl ow rate through

the heat exchanger is incorrect which will damage

the heat exchanger voiding the warranty! The

maximum allowable temperature rise is 35°F,

19.4°C

.

The maximum allowable fl ow rate through a LCD

boiler with copper heat exchanger is 92 GPM,

5.8 L/s

on 225-1200 models and 115 GPM,

7.3 L/s

on 1480 to 2300 models. The cupro-nickel heat

exchanger allows for 100 GPM,

6.3 L/s

on 225 to

1200 models and 125 GPM,

7.9 L/s

on 1480 to 2300

models.

Low Water Cutoff

If a boiler is installed above any radiation elements it

must be fi tted with a low water cutoff device.

Refer to wiring diagram supplied with the boiler/water

heater for proper wiring connections.

Expansion Tank & Air Separator

An expansion tank or other means to control thermal

expansion must be installed in the heating system. An

expansion tank must be installed close to the boiler on

the suction side of the pump. An air scoop and

automatic air vent must also be installed to eliminate air

trapped in the system.

Primary/Secondary Piping

Boilers connected to heating systems using zone valves,

zone pumps, or systems that have excessive fl ow rates

or return water temperatures less than

125°F

,

52°C

must be isolated from these systems to protect the boiler.

Variable Water Flows

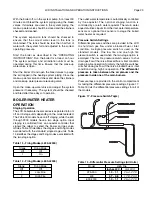

Figure 11 shows a typical primary/secondary piping

system. A dedicated pump is used to maintain a

constant water flow through the boiler. This boiler

pump is sized to overcome the head loss of the boiler

a n d n e a r p i p i n g w h i l e s u p p l y i n g t h e f l ow ra t e

required to maintain the desired temperature rise

across the boiler heat exchanger. The system pump is

sized to provide the required fl ow to the heating system.

The boiler piping connections to the heating system

piping must not be more than

12 in

,

305 mm

apart to

ensure zero pressure drop. See Figure 11.

Low Return Water Temperatures

To prevent the problems associated with condensation

of the products of combustion due to low return water

temperatures a primary/secondary piping system with

a bypass and bypass valve must be installed, see Figure

12. The bypass and bypass valve must be sized the

same as the boiler piping. A balancing valve must

also be installed in the supply side of the boiler piping

downstream of the bypass. The balancing valve

should be adjusted to divert some of the heated

discharge water into the return water until the required

inlet water temperature is achieved. The primary and

secondary pumps should be sized to provide the

required fl ow through each system. The boiler piping

connections to the heating system piping must not be

more than

12 in

,

305 mm

apart to ensure zero pressure

drop. See Figure 12.

Multiple Boiler Systems

Systems using multiple boilers can also be installed

using a primary/secondary manifold system, Figure 13.

Piping For Use With Cooling Units

The boiler, when used in connection with a refrigeration

system, must be installed so the chilled medium is piped

in parallel with the boiler. Appropriate valves must be

used to prevent the chilled water from entering the

boiler.

When a boiler is connected to a heating coil that may

be exposed to refrigerated air from an air handling

device, the piping system must be equipped with fl ow-

control valves or some other automatic means of

preventing gravity circulation of the boiler water during

the cooling cycle.