LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 25

Demand Satisfi ed:

1. When the demand for heat is satisfi ed the operator

switch will open, de-energizing relay R8, TD1, TD3,

TD4, the FSM, and the pilot, main and safety

solenoid valves. The pilot and main flames are

extinguished.

2. The blower delay timer TD3 starts the 80 second

post-purge timing. The blower(s) shut(s) off when

TD3 times out.

3. The pump delay timer TD4 starts the post-purge

timing. The pump(s) remain on for 0.1 to 10 minutes

then shut(s) off when TD4 times out.

High Limit, Low Water Flow, Low Gas Pressure, High

Gas Pressure, Power Venter Interlock Faults

1. Electrical power to the gas valves, blower(s) and

optional power venter will be interrupted if any safety

is tripped.

2. The manual reset high limit can be reset by

depressing the reset button on the left jacket

panel.

Low Air (Blocked Flue/Air Inlet)

• The pressure switch will monitor blower airfl ow.

• Air monitoring will begin at pre-purge. If a low air

condition is present power will not be supplied to the

FSM. The blower(s) will remain on.

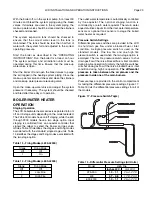

OPERATION SEQUENCE, 2 STAGE

OPTION L600 through L2300

Note: Refer to the wiring diagram included with the

unit for further control system info.

POWER ON:

Demand for Heat:

1. The low operator switch closes, energizing pump

delay timer TD4 and the water pump(s).

2. Water fl ow through the unit closes the water fl ow

switch contacts energizing blower delay timer TD3.

3. The system checks all primary limit(s) and other

inter-locks before starting pre-purge. The unit will not

start if any switch is open.

Prepurge:

1. Blower delay timer TD3 energizes the low speed

windings of the blower(s).

2. Once sufficient air pressure in the combustion

chamber is sensed the pressure switch closes

allowing the blower delay timer TD1 to start a 10

second pre-purge.

Ignition Trial:

1. Blower delay timer TD1 times out and the fl ame

sense module, FSM, is energized.

2. The FSM star ts the 10-second ignition trial,

energizing relay R7, the pilot solenoid valve and the

spark generator.

3. The pilot valve and spark generator are energized

for the 10-second ignition trial. When the pilot fl ame

is sensed, the FSM sends 24VAC to its MV terminal

energizing the safety and low fi re-side of the main

solenoid valves and relay R8, de-energizing R7 and

the spark generator.

4. If the pilot fl ame isn’t sensed, the FSM de-energizes

the PV terminal and waits 5 minutes before initiating

the second ignition trial. The blower(s), pump(s) and

optional power venter will remain on during this time.

5. On CSD-1 equipped units the blower(s) and optional

power venter will shut down and the boiler/water

heater will lock if the second ignition trial fails. The

unit must then be manually reset by depressing the

reset button on the left jacket panel.

6. On non-CSD-1 equipped units the FSM will wait 10

minutes after the second unsuccessful ignition

attempt then begin the ignition process described

in step 3 above. The FSM will continue to cycle the

unit through steps 3, 4 and 6 until the unit lights or

the demand for heat is removed.

Main Burner

Once the pilot is proven, the FSM sends 24VAC to its

MV terminal energizing the safety and low-fi re side of

the main solenoid valves.

Normal Operation

• Staging is controlled by the return water aquastat.

Relays R2 and R2R are energized by the return water

aquastat when more heat input is required. The

hi-speed windings of the blower(s) are energized.

• Relay R9 is energized when the hi-fi re pressure switch

senses adequate air pressure to sustain hi-fire

combustion. R9 energizes the hi-fi re side of the main

solenoid valve.

• Stage 1 will operate fi rst and last.

NOTE: For a change from stage 1 to 2, a 30 second

time delay is provided in the pressure switch

switching circuit. The time delay TD6 provides a

hold state that allows the blower to reach full speed

and close the high fi re pressure switch before it is

energized to confi rm proper air fl ow.