LCD INSTALLATION AND OPERATION INSTRUCTIONS

Page 12

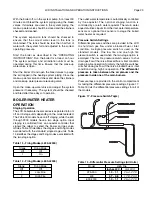

Figure 8 - Outdoor Venting

Figure 9 - Multiple Outdoor Units

COMMON VENT SYSTEMS

If an existing boiler/water heater is removed from a

common venting system, the common venting system may

then be too large for the proper venting of the remaining

appliances connected to it. At the time of removal of an

existing boiler/water heater, the following steps shall be

followed with each appliance remaining connected to the

common venting system placed in operation, while the

other appliances remaining connected to the common

venting system are not in operation.

Au moment du retrait d'une chaudière existante, les

mesures suivantes doivent être prises pour chaque

appareil toujours raccordé au système d'évacuation

commun et qui fonctionne alors que d'autres appareils

toujours raccordés au système d'évacuation ne fonction-

nent pas: système d'évacuation

a) Seal any unused openings in the common venting

system.

Sceller toutes les ouvertures non utilisées du sys-

tème d'évacuation.

b) Visually inspect the venting system for proper size

and horizontal pitch and determine if there is no

blockage or restriction, leakage, corrosion and other

defi ciencies which could cause an unsafe condition.

Inspecter de façon visuelle le système d'évacu-ation

pour déter miner la grosser et l'inclinaison

horizontale qui conviennent et s'assurer que le

système est exempt d'obstruction, d'étranglement

de fruite, de corrosion et autres défaillances qui

pourraient présenter des risques.

c) Insofar as is practical, close all building doors and

windows and all doors between the space in which

the appliances remaining connected to the common

venting system are located and other spaces of the

building. Turn on clothes dryers and any appliance

not connected to the common venting system. Turn

on any exhaust fans, such as range hoods and

bathroom exhaust, so they will operate at maximum

speed. Do not operate a summer exhaust fan for a

boiler installation. Close fi replace dampers.

Dans la mesure du possible, fermer toutes les

portes et les fenêtres du bâtiment et toutes les

portes entre l'espace où les appareils toujours

raccordés du système d'évacuation sont installés et

les autres espaces du bâtiment. Mettre en marche

les sécheuses, tous les appareils non raccordés au

système d'évacuation commun et tous les

ventilateurs d'extraction comme les hottes de

cuisinère et les ventilateurs des salles de bain.

S'assurer que ces ventilateurs fonctionnent à la

vitesse maximale. Ne pas faire fonctionner les

ventilateurs d'été. Fer mer les registres des

cheminées.

d) Place in operation the appliance being inspected.

Follow the lighting instructions. Adjust thermostat so

appliance will operate continuously.

Mettre l'appareil inspecté en marche. Suivre les

instructions d'allumage. Régler le thermostat de

façon que l'appareil fonctionne de façon continue.

e) Test for spillage at the draft hood relief opening after

5 minutes of main burner operation. Use the fl ame

of a match or candle, or smoke from a cigarette,

cigar or pipe.

Faire fonctionner le brûleur principal pendant 5 min

ensuite, déterminer si le coupe-tirage déborde à

l'ouverture de décharge. Utiliser la fl amme d'une

allunette ou d'une chandelle ou la fumée d'une

cigarette, d'un cigare ou d'une pipe.