8

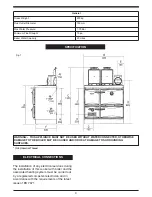

Fig.5

Especially Airtight Properties:-

If the cooker is being fitted in a property where the

design air permeability is less than 5m

3

/ (h.m

2

) (nor-

mally newer properties built from 2006), then a per-

manent ventilation must be fitted to provide 550mm

2

of ventilation for each kW of rated output. If a draught

stabiliser is also fitted then the requirement is

850mm

2

per kW of rated output.

Apply fire cement to the socket in the hob. Attach a

short length of 6” (150mm) I.D. pipe approx. 10”

(250mm) long to the outlet of the flue box by means

of fire cement. Place the flue box on the hob and the

pipe into the wall and consolidate the fluebox and pipe

into the fire cement. Apply 3 or 4 coils of 10mm (

1

/

2

’)

insulating rope to the pipe and fill the wall cavity with

fire cement. (See fig. 5).

FLUE BOX

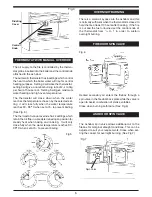

CENTRAL HEATING AND

HOT WATER SYSTEM

THIS APPLIANCE MUST NOT BE USED WITHOUT

WATER CONNECTED.

It is recommended that a 190 litre (40 galls) indirect

hot water storage cylinder of the double feed type e.g.

(Complying with BS. 1566 Part 1:DF Type 10) should

be lagged and fixed vertically as near as possible to

the cooker.

The 28mm minimum diameter primary flow and return

pipes must not exceed 10m in length and pipes longer

than 5m must be lagged.

Ensure that the flow pipe has an open vent and rises

continuously from the boiler to the cylinder to ensure

good gravity circulation.

In combined systems, the water draw-off pipes to the

taps must be dead-leg connection from the vent/ex-

pansion pipe.

There are only two boiler tappings on this cooker and

a typical design layout is shown in Fig. 6.

An injector tee is provided which must be fitted to en-

sure adequate primary flow circulation when the water

circulator is operating, otherwise there may be a lack

of domestic hot water. The heating flow and return

pipes may be 22mm, the return pipe being connected

to the 28mm primary return by the injector tee, and

the tee outlet connected to the boiler return pipe.

All installations must be fitted with a drain tap at the

lowest point of the system.

Inhibitor

A corrosion inhibitor

MUST

be added to the heating

system to protect the heat exchanger and pipework.

Inhibitor must also be replaced if the system is

drained after installation. As a precaution, the heating

system

MUST

also be flushed out prior to the addition

of the inhibitor to ensure any flux, debris is removed.

Typical Central Heating/Hot

Water System

Fig.6

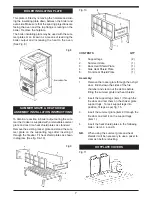

CENTRAL HEATING PUMP CONTROL

The central heating pump must be controlled by fitting

a pipe thermostat on the flow pipe as close as possi-

ble to the cooker. If it is used on its own it should be

set to approx. 55

o

C

Содержание 370 SFW

Страница 11: ...11 EXPLODED VIEW ...

Страница 13: ...13 NOTES ...

Страница 14: ...NOTES 14 ...

Страница 15: ...15 NOTES ...

Страница 29: ...13 NOTES ...

Страница 30: ...14 NOTES ...

Страница 31: ...15 NOTES ...