12

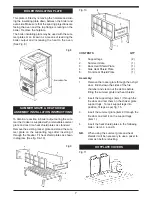

PARTS LIST

1.

Spin Valve

B00032AXX

2.

Front Cleaning Door

B00164BXX

3.

Bonnet Blanking Plate

B00296AXX

4.

Fire Door

B00558AXX

5.

Oven Door

B00559AXX

6.

Ash Door

B00560AXX

7.

Warming Oven Door

B00561AXX

8.

Ash Door Back

B00562AXX

9.

Bonnet

B00571AXX

10.

Bonnet Cover

B00572AXX

11.

Bonnet Spin Valve

B00573AXX

12.

Trivet

B00574AXX

13.

Front

B00584AXX

14.

Hob

B00644AXX

15.

Riddling Handle

F00063AXX

16.

Thermostat Holder

F00076AXX

17.

Side Panel

F00078AXX

18.

Back Panel

F00079CXX

19.

Upper Blanking Plate

F00082AXX

20.

Front Cover Plate (Short)

F00083AXX

21.

Front Cover Plate (Long)

F00084AXX

22.

Fire Bar Link

F00097AXX

23.

Donard SF Ashpan

F00100AXX

24.

Base

F00101DXX

25.

Boiler

F00102DXX

26.

Lower Blank Plate

F00117AXX

27.

Main Oven Door Panel

F00906AXX

28.

Warming Oven Door Panel

F00907AXX

29.

RH Strap

F00911BXX

30.

Base Plate

F00914AXX

31.

Fix Plate RH

F00915AXX

32.

Fix Plate LH

F00916AXX

33.

Hob Back Filler Piece

F00986AXX

34.

Oven Side Flue Plate

F01001AXX

35.

Hinge Cover Plate

F01257AXX

36.

Thermostat Without Knob

G00004AXX

37.

Thermometer 100 to 300

G00519AXX

38.

Main Oven Door Insulation

J00230AXX

39.

Warming Door Insulation

J00231AXX

40.

Serial Number Plate

N00234BXX

41.

Gasket (200 * 43 * 2mm)

P00011BXX

42.

Silicone Oven Seal 266mm

P00097AXX

43.

Silicone Oven Seal 312mm

P00098AXX

44.

Silicone Oven Seal 416mm

P00099AXX

45.

Steam Escape

Q00107AXX

46.

Riddling Grate

Q00113AXX

47.

Fire Bar Standard

Q00148AXX

48.

Fire Bar Frame

Q00149AXX

49.

Hotplate

Q00152AXX

50.

Cleaning Plateto Hotplate

Q00154AXX

51.

Front Cleaing Door Clip

Q00158AXX

52.

Summer Grate Support

Q00162AXX

53.

Summer Front Brick

Q00163AXX

54.

Summer Back Brick

Q00164AXX

55.

Summer Side Brick

Q00165AXX

56.

Baffle

Q00166BXX

57.

Base Plate

Q00168BXX

58.

Oven Bottom Back

Q00169AXX

59.

Oven Bottom Side (Left)

Q00170BXX

60.

Oven Bottom Side (Right)

Q00171BXX

61.

Oven Bottom

Q00172BXX

62.

Top Oven Back

Q00173BXX

63.

Right Side Oven Top

Q00176CXX

64.

Top Oven Side (Left)

Q00177AXX

65.

Oven Top

Q00187CXX

66.

Fire Bar Special

Q00233AXX

67.

Cleaning Plate To Hob

Q00590AXX

68.

Flue Way Right

Q00735BXX

69.

Fire Door Back

Q00746AXX

70.

Oven Damper

Q00749AXX

71.

Lining Panel - 300

RO2E340773

72.

Strap - Lid Centre Fixing

RO2M342362

73.

Cup - Coil Handle

RO4M340521

74.

Coil Handle

RO4M340522

75.

Insulating Cover

RO4M342347

76.

Insulating Cover Base

RO5E342348

77.

Hinge Butt” (Black)

U00029AXX

78.

Oven Damper Knob (Black)

U00032AXX

79.

T/Stat Knob (Black)

U00094AXX

80.

Towel Rail Bracket RH

U00106AXX

81.

Towel Rail Bracket LH

U00107AXX

82.

RH Door Handle (Black)

U00156AXX

83.

Extended Hinge (Black)

U00158AXX

84.

Lid Hinge

U00197AXX

85.

Boiler Plug

V00016AXX

86.

Cleaning Brush

V00072AXX

87.

Poker

V00073AXX

88.

Scraper

V00074AXX

89.

Roasting Tin

V00091AXX

90.

Oven Shelf

V00092BXX

91.

Stay Rod

V00096AXX

92.

Secondary Air Pipe

V00097AXX

93.

Grill For Roasting Tin

V00099AXX

94.

Ashpan Lifter

V00499AXX

95.

Towel Rail Bung

V00522AXX

96.

Port Hole Cover

V00774AXX

97.

Spacer

V00775AXX

98.

Pivot Pin

V00800AXX

99.

Catch

V00801AXX

100.

Fix Spindle

V00802AXX

101.

Torsion Spring 1557 RH

V00865AXX

102.

Towel Rail

V00888AXX

103.

Damper Axle

V00905AXX

104.

Badge

V01040AXX

105.

Steam Vent

W00904AXX

106.

Stay Rod Nut

W00920AXX

107.

Stay Rod Nut Cap

W00923AXX

No.

Description

Code

No.

Description

Code

Содержание 370 SFW

Страница 11: ...11 EXPLODED VIEW ...

Страница 13: ...13 NOTES ...

Страница 14: ...NOTES 14 ...

Страница 15: ...15 NOTES ...

Страница 29: ...13 NOTES ...

Страница 30: ...14 NOTES ...

Страница 31: ...15 NOTES ...