Where the chimney is believed to have previously

served an open fire installation it is possible that the

higher flue gas temperature from a closed appliance

may loosen deposits that were previously firmly ad-

hered, with the consequent risk of flue blockage. It is

therefore recommended that the chimney be swept a

second time within a month of regular use after instal-

lation.

WARNING: PROLONGED SOOT FORMATION MAY

RESULT IN THE FLUEWAYS BECOMING

BLOCKED AND COULD GIVE RISE TO THE RE-

LEASE OF CARBON MONOXIDE, A POISONOUS

GAS, INTO THE ROOM.

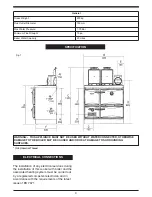

The position of available types of flue layouts are

shown in Figs. 2, 3 and 4, the cooker flue chamber is

adaptable to provide either top or back flue outlets,

by means of the reversible loose socket.

(a)

Rear Flue Outlet

This must only be used where there is a brick flue

immediately behind the cooker. Provision must be

made for a condensate collecting vessel and

cleaning door. See Fig. 3.

NOTE:

MAXIMUM HORIZONTAL LENGTH 150mm.

EXTENDED REAR FLUE PIPE AND BENDS

ARE NOT RECOMMENDED.

(b)

Top Flue Outlet

The cooker should be connected to the main flue

via a 150mm minimum diameter cast iron pipe or

appropriately sized vitreous enamelled mild steel

pipe and be sealed to the cooker flue chamber

with soft rope and fire cement.

Any bends in the flue pipe must be not less than

135º (45º from horizontal) and be complete with

a cleaning door.

COOKER FLUE CONNECTION

Fig. 2

DESN 515206

Fig. 3

Fig. 4

DESN 515207

DESN 515208 A

A minimum 6” vertical length of flue pipe must be fitted

before any bend is included.

6

Содержание 370 SFW

Страница 11: ...11 EXPLODED VIEW ...

Страница 13: ...13 NOTES ...

Страница 14: ...NOTES 14 ...

Страница 15: ...15 NOTES ...

Страница 29: ...13 NOTES ...

Страница 30: ...14 NOTES ...

Страница 31: ...15 NOTES ...