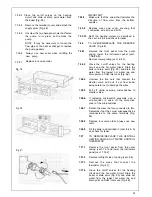

Locate the sealing washer fixing the twin flue

header as illustrated making sure that the

inner aluminium exhaust locates firmly in the

outlet spigot. Make sure that the screws are

satisfactorily located through the gasket seal.

Locate the 2 x 80 mm ‘0’ rings in the twin

90” M/F bend consisting of.

90” elbow with ‘0’ ring side F

80 mm dia ‘0’ ring

f l u e h e a d e r .

Figures show the versatility of this flueing

system. Measurements and bends must be

calculated correctly so as not to oversize

maximum flue lengths.

All located ‘0’ rings must be lubricated with

a silicone grease to ensure easy, snug fit.

NOTE: Exhaust flue must slope 2” down

towards the boiler 35 mm fall per metre.

Spacing Clips

Spacing clips are available on request

should they be required.

NOTE: for eccentric vertical flue a 125 mm

(5 in) diameter flashing plate will be

required.

135” M/F bend consisting of.

135” elbow with ‘0’ ring side F

80 mm dia ‘0’ ring

Vertical eccentric flue exhaust duct

E = EXHAUST

I = INLET

T = TERMlNAL

Exhaust/suction system with concentric pipes for flat

or sloping roofs. Extensions with two separate pipes.

Maximum distance = I + E + T = 2 Metre + 2 Metre +

1 Metre = 12 Metre maximum (pipe + terminal).

Minimum distance D = T = 2 metre.

Exhaust terminal must not be cut.

NOTE: The pressure loss for each elbow fitted is:

90” slow bend less 3 metre of pipe for each one

fitted.

135” bend less 1.5 metre of pipe for each one fitted

NOTE:

If bends are used in the exhaust flue then horizontal

sections must be avoided and there must be a 2”

slope towards the boiler 35 mm fall per metre.

IMPORTANT: See Fig. 42 for terminal clearances.

51

Содержание CSI 85

Страница 26: ...27...

Страница 42: ......

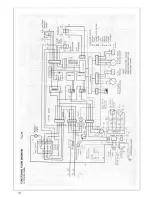

Страница 45: ...SECTION 9 ELECTRICAL SYSTEM DIAGRAM Fig 94 46...

Страница 46: ...47...

Страница 47: ......

Страница 48: ...49...

Страница 52: ......

Страница 55: ...Chartists Way Morley Leeds LS27 9ET Telephone 0113 252 7007 Tfax 0113 238 0229...