Page 10 of 22

IN052 Rev. K 0613

INSTALLATION INSTRUCTIONS

1

2

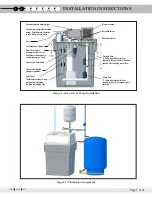

2.3. Plumbing Hook-up

All plumbing should be performed in accordance

with Local and State Codes by a Qualified Plumber.

1.

Shut off water main valve located after the pres-

sure tank.

2.

Drain water line.

3.

Plumb system into water line after the pressure

tank and all other water treatment equipment.

(Exception: Install before activated carbon filter/

tank.)

4.

Plumb appropriately to “Water In” and “Water

Out”. (Figure 6)

For ease of installation and servicing a ¾” sharkbite

fitting is provided on the inlet. This is compatible

with 3/4” pex or copper tubing.

5.

From the open leg of the inlet tee run pipe/tubing

thru a bypass valve to a second tee.

6.

Plumb unit as shown in Figures 6, 7 and 7a. The

Bladder Tank must be connected to the Rise Leg

of the Tee provided on the System Outlet, without

any elbows between the Tee and Tank.

Warning: An undersized bladder tank will result in

premature pump failure.

Note: Pipe supports are required, particularly to

support the bladder tank. These are not shown, as

installation details vary by property.

7.

Plumb the water line to the house into the open

leg of the second tee. (Figure 7) It is recommended

that a flow control valve be installed in this line.

8.

The built-in pump pressure switch and pressure

regulator provided are designed for use with a

pressure tank. The pressure tank bladder pressure

should be set per the tank manufacturers recom-

mendations for a pressure switch setting of 37 psi.

9.

An outlet pipe must be installed in the overflow

connection (figure 6) and connected to drain or

sump in accordance to Local and State Codes.

Warning: Overflow may occur due to a blocked vent

pipe, debris in or wear of the solenoid valves, or incorrect

connection to the electrical supply. Failure to connect

the overflow to a drain or sump (with sump pump or

other means of external discharge) may flood the area

around the unit in the event of overflow occurring.

10.

With the system in bypass mode, slowly open the

main water valve and check for leaks.

11.

Remove tank cover and slowly change bypass

valve to service configuration and check for leaks.

Figure 6 - Rear View, Unit Only

Figure 7 - Water Connections

Figure 7a - Water Connections

Overflow, connect to

drain or sump per local

and state codes

Outlet Tee provided with Unit.

Bladder Tank to be connected to

Tee Rise Leg. Do not install bends

between Tank and Tee.

Bladder tank

Minimum capacity

5 Gal. (Required)

Outlet valve

(Recommended)

Pressure gauge

(Optional)

Inlet valve

(Recommended)

Water out, to house

Flow control valve

(Recommended)

Bypass valve

(Recommended)

Existing house

pressure tank

(Tank tee, pressure switch,

pressure gauge and relief

valve not shown.)

Water in,

From well pump

Vent hole, breaks

siphon if unit overflows.

To bladder tank

Water in

Water out

Overflow, to be

connected to drain

or sump