6.7 F.I.N.D.A explained

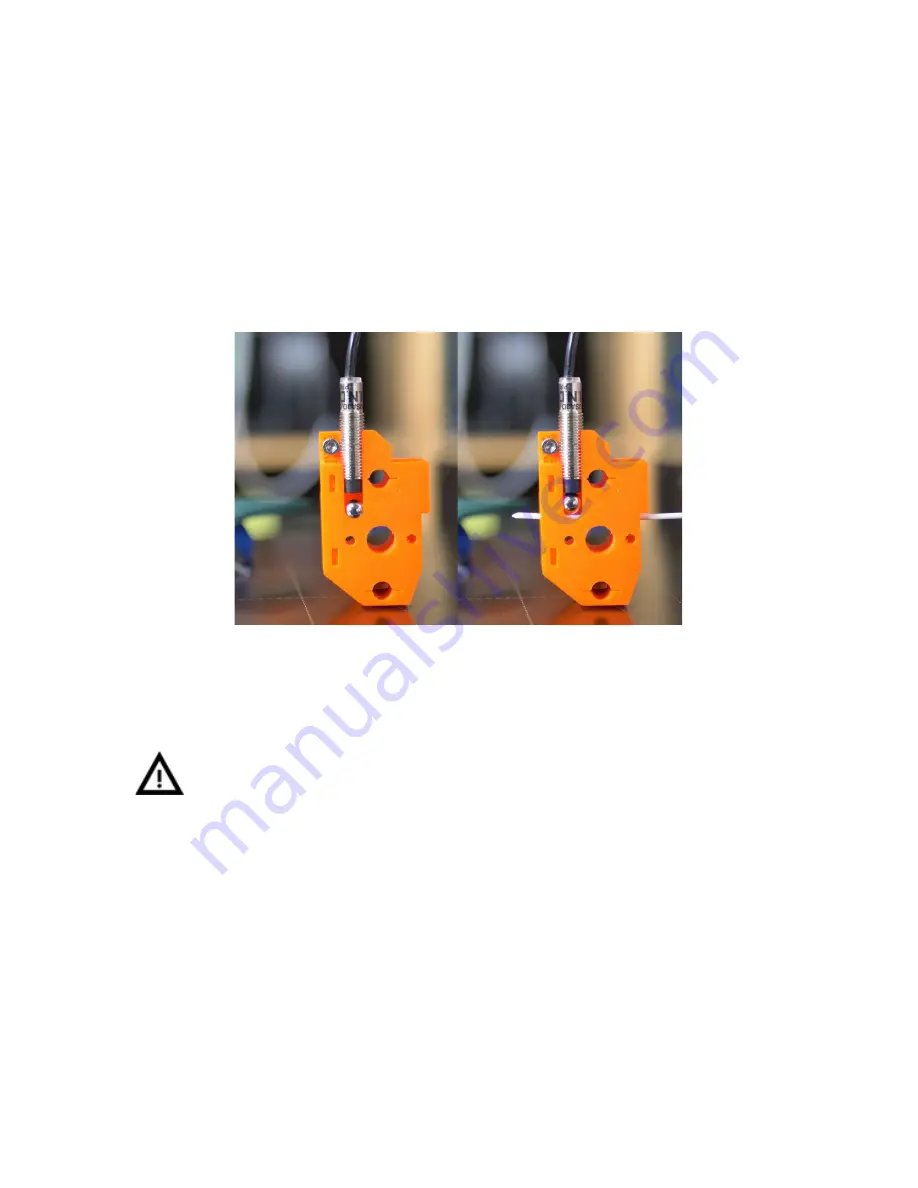

F.I.N.D.A is an older design P.I.N.D.A probe repurposed as a filament sensor. When the

filament is pushed through the selector, it raises a stainless steel ball. Its movement is

detected by the F.I.N.D.A. There is a small red LED light on the back of the probe. As soon

as the filament is detected, the light turns off.

When the filament is removed, the stainless steel ball falls back down. Please note that the

ball is pulled down by gravity, that means the filament sensor won’t work if you for whatever

reason turn the MMU2S unit upside down.

Pict.12 - F.I.N.D.A.

7 Calibration

Since the assembly of the MMU2S requires the printer’s extruder to be

disassembled in the process, it’s very likely that your printer’s Z-axis is now shifted.

It’s essential to

re-calibrate the Z-axis

and run the

First Layer Calibration

routine

before you start printing!

7.1 IR filament sensor calibration

The calibration of the IR sensor is based on the correct position of the chimney with the

sensor (IR sensor holder) on the extruder. Calibration is purely mechanical.

1. Before you start, make sure that the

filament is not loaded

!

2. Unscrew the Festo fitting on the extruder.

3. Open the

LCD menu - Support - Sensor info

and focus on

IR value

.

4. Loosen both M3 screws on the chimney (green marks).

15

Содержание i3 MK2.5S Multi Material Upgrade 2S

Страница 1: ...ENG ...