MaInTenanCe

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

21

End of Heating season

1. Thoroughly clean the exhaust area, secondary burn

chamber, and flues of any loose or crusted ash

buildup. Crusted ashes are easier to remove when

furnace is still warm. Note: a thin black coating in

the firebox is acceptable, but ensure that there is no

ash in contact with bare metal.

2. Check for damaged brick and replace as necessary.

Contact your dealer for replacement brick.

3. Inspect and clean air passage under right hand

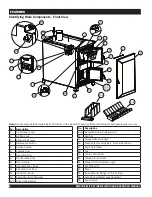

firebox brick. See Figures 2-4.

a. Remove bricks to expose air passage. Clean areas

as needed.

b. Turn blower on by moving lever to the right into

the Run position and check for airflow in front

right hand corner of the firebox. See Figures 2-4.

If there is no airflow, remove clean out cover and

clean.

c. Install bricks (see Brick Layout applicable to

furnace model on pages 26 and 27).

4. Check to ensure there is no moisture in any part of

the inside of the firebox, secondary burn chamber,

or exhaust area. Apply a thin film of oil in the flue

area and exhaust area.

5. Chimney must have a rain cap.

Failing to properly clean the furnace and protect it from

moisture during the off-season will void the warranty.

6.

dO nOt

run the furnace in the summer months when

the load demand is very low (ie., only domestic hot

water is being heated.)

7. Ensure the water reservoir is full during the non-heating

season to prevent corrosion inside the water jacket.

8. Ensure proper amount of water treatment is in the

system. In the event that there has been water loss

through the season, additional water treatment will

need to be added. Follow the treatment ratio on the

bottle for additional gallons of water added to the

system. It is acceptable to add more than is specified

on bottle. Operate the water circulating pump for 24

hours after adding water treatment to ensure proper

mixing of the water treatment with the water.

9. A water sample must be drawn 30 days after purchase

of the unit and forwarded to your dealer for testing.

Maintain the results of this test on file. Thereafter, draw

a water sample once a year and forward to your dealer

for testing.

Water properly treated with Pro-Fab approved water

treatment should have a ph level between 8.8 and

11.0, a nitrate level between 730 and 1460 ppms

as NaN02, and a conductivity must be less than or

equal to 4000 mmhos.

If the pH is not within tolerance, treat by adding a ratio

of 1 part of Pro-Fab approved Wood Burning Furnace

Treatment (WBFT) to 300 parts of system water and

retest after one week. If the nitrate is less than 730

ppm, treat by adding a ratio of 1 part WBFT to 300

parts of system water and retest after one week. If

the conductivity is higher than 4000 micromhos,

drain 50% of the system water. Refill and treat by

adding a ratio of 1 part WBFT to 300 parts of system

water and retest after one week.

Failing to use pro-Fab approved water treatment

in accordance with the Installation and Operation

Instruction manual will void the warranty. see

your dealer for authorized supplies. It is the

responsibility of the owner to maintain yearly

water sample results on file.

Empyre Elite Xt

200

Figure 4

Содержание Empyre Elite XT

Страница 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Страница 2: ......

Страница 31: ......