MaInTenanCe

20

EmpyrE ElItE Xt InstallatIOn and OpEratIOn manual

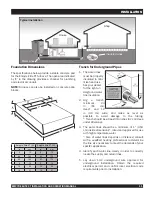

during Heating season

1. Establish a daily routine for storage of fuel and care of

the furnace. Check frequently for crusted ash buildup

until experience shows how often cleaning is necessary.

Be aware that the hotter the fire, the less creosote, and

that weekly cleanings may be necessary in mild weather,

even though monthly cleanings may be enough in the

coldest months. Have a clearly understood plan in place

in the event of a chimney fire.

2. The secondary burn chamber must be cleaned out

weekly as necessary. Ensure that the ash clean out

door is securely closed after each cleaning.

Place ashes in a steel container with a tightly fitting lid.

Other waste should not be placed in the container with

the ashes.

3. Check the water level daily, ensure the level is well

above the “ADD” mark.

Oxygen buildup causes corrosion inside the water system.

Keeping the water reservoir completely full prevents

oxygen buildup, especially during the summer months

when the furnace is not in use.

4. Check the door and lid gaskets to ensure an air tight fit.

Adjust hinges and latch as needed.

5. Check and clean the heat exchanger flues weekly. A

buildup in the flues and chimney will cause a poor draft

and reduce efficiency.

6. Check and clean the air passages in the upper loading

door frame several times during the heating season. To

clean the air passages, remove the air pan.

To remove the air pan, swing the smoke curtain into the

horizontal position and pull the air pan lock forward. See

Figure 1. Drop the air pan down and pull forward, removing

the air pan with the smoke curtain.

Inspect and clean the two rectangular air passages on

the upper door frame as well as removing any buildup on

the air pan. Move Run

/

Load lever to expose air passages.

Move the Exhaust Exit lever back and forth to ensure easy

movement.

To reinstall, guide the air pan into the slots on either side of

the door frame. See Figure 1. Push in and up, and secure

in place by pushing the air pan lock back into the lock

position.

7. Cover plates and guards must be in place at all times,

except during maintenance and servicing.

8. Rear access door must be secured with latch lock bolt.

See page 9. Tighten with a wrench.

9. All doors must be closed during operation.

10. Operate the backup heating system (gas, oil or electric)

periodically to ensure that it will operate satisfactorily

when needed.

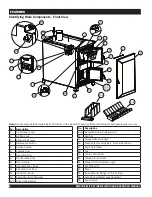

air pan

air pan

mounting notches

smoke

Curtain

air pan

lock

2 air

passages

Clean Out

Cover

Empyre Elite Xt

100

Figure 1

Figure 2

Figure 3

Содержание Empyre Elite XT

Страница 1: ...Installation and Operation Instructions Empyre Elite XT Model 100 and 200...

Страница 2: ......

Страница 31: ......