AIR 40, AIR Breeze, AIR 30, AIR X MARINE and AIR SILENT-X are trademarks of Primus Wind Power 2013 Primus Wind Power Inc.

AIR Owner’s Manual

3-CMLT-2020-A

15

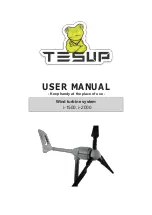

Yaw pivot

& clamp

Tower

tubing

M5 Socket head screw

5/32”

(comes imbedded in Hex

yaw assembly) wrench

STEP 4: Attach Turbine to Tower

4.) Insert tower into yaw assembly.

5.) Ensure yaw pad is in place.

6.) Apply Tef-Gel w/ applicator provided to yaw bolts prior to assembly.

Tighten screws to secure turbine to tower. It is important that Tef-Gel

is applied to all hardware prior to final assembly.

7.) Ensure turbine is securely attached to tower.

8.) Ensure wire connections are secure and double check for initial two

blinks by “powering up” turbine prior to raising the tower. This is especially

important when installed on boats or structures.

1.) Insert yaw pad into yaw pivot point/clamp assembly.

2.) NOT SHOWN: Complete turbine wiring connections.

3.) After assembling the yaw clamp, insert yaw/wires into the tower, lift

the yaw clamp assembly 1/8” to secure the yaw onto yaw pad to prevent

metal to metal contact and reduce vibration down-tower. This is espe-

cially important when mounted on boat or structures.

IMPORTANT: Apply Tef-Gel to yaw bolts prior to assembly.

Observe torque specs during assembly.

WARNING:

The yaw pad is critical to ensuring proper and secure

turbine mounting to the tower; however, in some instances it

makes it difficult to tell if the tower is properly inserted into the

yaw assembly. Check this carefully before raising the tower.

IMPORTANT:

Further inspection of the blade bolts, yaw bolts and

rotor nut are recommended and re-tightened within 30 days after

initial installation.