Introduction - Page 4

Gas Safety (Installation & Use) Regulations 1994.

This appliance must be installed and serviced by a

competent person, in accordance with the above regulations.

In the UK 'Corgi' Registered Installers (including the regions

of British Gas Plc) undertake the work to a safe and

satisfactory standard.

Failure to install appliances correctly could lead to

prosecution.

It is in your own interest, and that of safety, to ensure that

the regulations are complied with.

The Ultra 2 boilers are range ratable and are factory set to

the maximum output.

The boilers are designed for use on

sealed water systems

only

, with an indirect hot water cylinder.

THEY MUST NOT BE CONNECTED TO A DIRECT

CYLINDER.

The boilers are for use on Natural Gas (G20) only.

Samples of the Potterton Ultra 2 gas system boilers have

been examined by B.S.I., a United Kingdom Notified Body.

The range is certified to comply with the essential

requirements of the Gas Appliance Directive, the Low

Voltage Directive and shows compliance with the Electro

Magnetic Compatibility Directive 89/336/EEC and are

therefore permitted to carry the CE Mark.

Delivery & Kits Available

The unit is delivered in two packages (1) the boiler with

fittings and (2) the flue/terminal assembly.

A 1m Flue Extension Kit is available (the total flue length

must not exceed 3 m).

An Internal Programmer is also available that fits into the

facia.

A Vertex Flue Kt is available which allows the flue to exit

vertically from the boiler (maximum length is 4.17 m).

A Vertical Balanced Flue Kit is available which allows the

flue to exit vertically from the boiler (maximum length

3.25m).

A Wall Spacing Kit is available which allows pipe-work to run

behind the boiler.

A Fit From The Inside Flue Kit is available which allows the

flue/terminal assembly to be fitted from inside the building.

1. Installation Requirements - Page 4

1.1

Health and Safety Information for the

Installer and Service Engineer

Under the Consumer Protection Act 1987 and Section 6 of

the Health and Safety at Work Act 1974, we are required to

provide information on substances hazardous to health.

Small quantities of adhesives and sealants used in the

product are cured and present no known hazards.

The following substances are also present.

Insulation and Seals

Material -

Ceramic Fibre. Alumino - Silicone Fibre.

Description

- Boards, Ropes, Gaskets.

Known Hazards

- Some people can suffer reddening and

itching of the skin. Fibre entry into the eye will cause

foreign body irritation. Irritation to respiratory tract.

Precautions

- People with a history of skin complaints may

be particularly susceptible to irritation. High dust levels

are only likely to arise following harsh abrasion. In

general, normal handling and use will not present

discomfort, follow good hygiene practices, wash hands

before consuming food, drinking or using the toilet.

First Aid

- Medical attention must be sought following eye

contact or prolonged reddening of the skin.

Heat Exchanger

Material

- Copper with lead/tin coating.

Description

- Finned copper tube.

Known Hazards

- Inhalation or ingestion of lead dust or

fumes may cause headache and nausea.

Precautions

- Unused heat exchangers present minimal risk

to health other than normal hygiene practices would

demand regarding washing before eating etc. Deposits

found on or below a heat exchanger that has been in use

could contain lead oxide. Avoid inhalation by using a

vacuum cleaner in conjunction with other cleaning tools

when servicing the boiler.

1.2

Codes of Practice

The boiler must be installed in accordance with: The Gas

Safety (Installation and Use) Regulations 1994 and the

current issue of:-

The Building Regulations, Building Standards (Scotland)

Regulations, Local Building Regulations, Model and local

Water Undertaking Bye-laws, IEE Wiring Regulations and

Health & Safety Document No. 635 "The Electrician At Work

Regulations 1989".

Detailed recommendations are stated in the following British

Standards: BS6891:1988, BS6798:1987, BS5546:1990,

BS5440:1:1990, BS5440:2:1989 and BS5449:1990.

Содержание Ultra 2

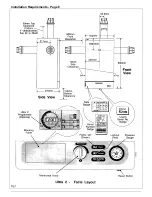

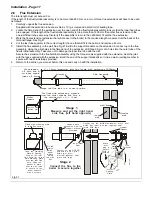

Страница 6: ...Installation Requirements Page 6 Fig 1 ...

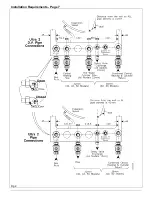

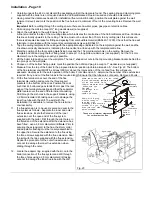

Страница 7: ...Installation Requirements Page 7 Fig 2 ...

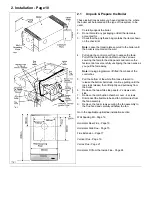

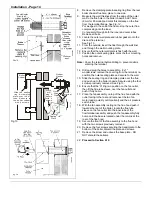

Страница 9: ...Installation Requirements Page 9 ...

Страница 37: ...Routine Maintenance Page 37 ...

Страница 51: ...7 Wiring Diagrams Page 51 ...

Страница 52: ...Wiring Diagrams Page 52 Ultra 2Dv ...

Страница 53: ...Wiring Diagrams Page 53 Ultra 2 ...

Страница 54: ...54 Fault Finding Part No 405 0522 8 Fault Finding Guide Page 54 ...

Страница 55: ...Part No 405 0522 Fault Finding 55 Fault Finding Guide Page 55 ...

Страница 56: ...56 Fault Finding Part No 405 0522 Fault Finding Guide Page 56 ...

Страница 57: ...Part No 405 0522 Fault Finding 57 Fault Finding Guide Page 57 ...

Страница 58: ...9 Short List Of Spare Parts Page 58 ...