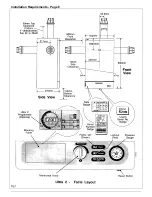

Installation - Page 19

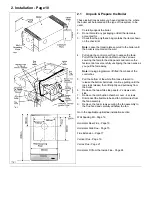

1.

Carefully unpack the kit, do not discard the packaging until all the items are found. The sealing ring and clamping plate

supplied with the boiler are not required when the Vertical Balanced Flue kit is used and should be discarded.

2.

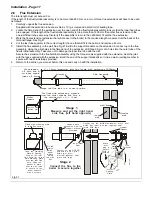

Having noted the clearances needed for installation (flue terminal & boiler), position the wall plate against the wall

(ensure it is level) and mark the position of the flue hole and a minimum of four of the mounting holes. Remove the wall

plate.

Important:

Before cutting through the ceiling ensure there are no water pipes, gas pipes or electric cables.

3.

Drill and plug the wall to accept 2½" long woodscrews (not supplied).

4.

Attach the wall plate to the wall. Ensure it is level.

A line is marked at the top of the mounting plate which indicates the centre line of the Vertical Balanced Flue. Continue

this line vertically upwards to the ceiling. This line must not be closer than 75 mm to any ceiling joist, this will ensure

there is adequate clearance for fitting and spacing from combustible material (BS5440:1:1990). Check that the flue will

terminate in accordance with the relevant recommendations given in BS5440:1.

5.

Tape the ceiling template to the ceiling with the appropriate edge (indicated on the template) against the wall, and the

line drawn vertically downwards, indicating the flue centre line, lined up with the template centre line.

6.

Mark the position of the four sealing plate fixing holes and the 134 mm diameter hole on the ceiling. Remove the

template and drill and plug the four fixing holes to accept 1 in long No.8 woodscrews (not supplied). Cut the 134 mm

diameter hole in the ceiling as neatly as possible.

7.

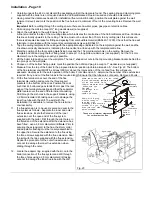

Lift the boiler into position over the wall plate. The two V shaped cut outs in the top mounting bracket locate behind the

two prongs on the wall plate.

8.

Choose on of the bottom fixing points, mark the position then drill and plug to accept a 1" woodscrew (not supplied).

9.

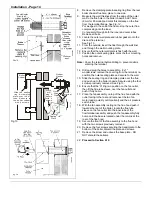

Measure from the top of the boiler to the proposed terminal position to obtain dimension ‘A’ - See Fig. 22. The bottom

of the flue terminal cowl MUST be at least 300 mm above the inter-section of the roof and flue, this will ensure

adequate clearances for the safe operation of the boiler. From dimension ‘A’, determine the number of flue extensions

required, if any, and cut the flue tubes to the required length. Ensure that the tubes are cut square. Remove all burrs.

10.

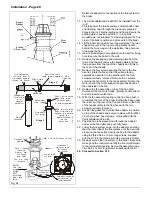

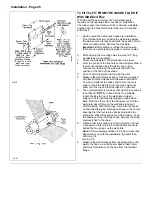

Fit the flue terminal cowl over the end of the flue

terminal die-casting and secure the three support

brackets to the bottom of the cowl. Position the cowl

such that it’s bottom edge extends 30 mm past the rear

edge of the terminal die-casting and that the separator

plate locates over the end of the terminal die-casting.

Drill through the six holes in the support brackets, using

a 2.8mm diameter drill, taking care not to damage the

inner flue tube with the drill. To assist with the

installation it is advisable to remove the flue terminal

cowl assembly.

11.

If a flue extension is to be used, secure and seal to the

flue system as follows:- Separate the inner and outer

flue extensions, locate the flared end of the inner

extension over the open end of the flue system

supplied with the boiler. Drill through the pilot holes, in

the flared end of the extension after the extension has

been fitted - use a 2.8 mm diameter drill.

Note:

Prior to

securing the extension(s) to the flue, the storm collar

and adjustable flashing must be loosely assembled to

the upper flue. Secure the extension to the flue using

the three screws supplied with the flue extension. Seal

the joint with the tape supplied with the flue extension.

Repeat the procedure for the outer flue extension - take

care not to damage the inner flue extension when

drilling through the outer.

12.

Locate the adaptor ring, supplied with the kit, onto the

boiler connection of the flue system and drill through

the three holes using a 2.8 mm diameter drill, taking

care not to damage the inner flue tube with the drill.

U

L

0

0

1

0

9

B

36mm

Side

Clearance

Spirit

Level

36mm Side

Clearance

515mm

Bottom

Clearance

Mark the centre line up to the ceiling

& with the sealing template mark

off t he flue centre. Cut a

134mm diameter hole.

Make sure you

DO NOT

cut through roof

members,

cables Or Pipes

These are minimum clearances

for vertical/vertex flue

170mm

Sealing

Template

Mark, drill & plug

4 holes ready to

take the wall

mounting plate securing

screws, (if a you hit a

brick joint use other

holes provided).

Fig. 23

Содержание Ultra 2

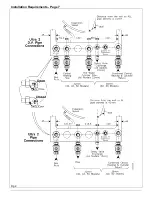

Страница 6: ...Installation Requirements Page 6 Fig 1 ...

Страница 7: ...Installation Requirements Page 7 Fig 2 ...

Страница 9: ...Installation Requirements Page 9 ...

Страница 37: ...Routine Maintenance Page 37 ...

Страница 51: ...7 Wiring Diagrams Page 51 ...

Страница 52: ...Wiring Diagrams Page 52 Ultra 2Dv ...

Страница 53: ...Wiring Diagrams Page 53 Ultra 2 ...

Страница 54: ...54 Fault Finding Part No 405 0522 8 Fault Finding Guide Page 54 ...

Страница 55: ...Part No 405 0522 Fault Finding 55 Fault Finding Guide Page 55 ...

Страница 56: ...56 Fault Finding Part No 405 0522 Fault Finding Guide Page 56 ...

Страница 57: ...Part No 405 0522 Fault Finding 57 Fault Finding Guide Page 57 ...

Страница 58: ...9 Short List Of Spare Parts Page 58 ...