Commissioning - Page 35

3.6

Advise the User

1.

If a programmer is fitted, set the timer to the correct time and programme the required settings. For a wall mounted

programer, see separate programmer instructions. For the Ultra 2 programmer, see the boiler Instructions for Use.

2.

Hand the Instructions for Use, these Installation & Service Instructions (and the programmer instructions) to the User

and instruct in the safe operation of the boiler and controls.

3.

Advise the User of the precautions necessary to prevent damage to the system and to the building in the event of the

system remaining inoperative during frost conditions.

4.

Advise the User that for continued efficient and safe operation of the boiler it is important that adequate servicing is

carried out at least once a year by the local Gas Region or a C.O.R.G.I. registered Installer.

5.

Advise the User how to 'Top Up' the system, to maintain pressure.

6.

Leave a permanent card attached to the boiler giving:

a.

Name and address of installer.

b.

Date of installation.

c.

A wiring diagram of the circuit.

4. Annual Service

To ensure continued efficient operation of the appliance, it is recommended that it is checked and cleaned as necessary at

regular intervals.

The frequency of servicing will depend upon the particular installation conditions and usage but in general once per year

should be adequate.

It is the law that any service work must be carried out by a competent person such as British Gas or other C.O.R.G.I.

Registered Personnel.

The following aspects of the boiler and installation should be examined, and rectified as necessary.

1.

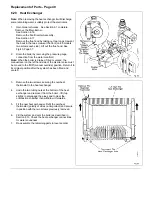

Check that the system pressure is 0.8 bar (cold).

2.

Run the boiler and check the operation of its controls and ensure that it responds to any switches and programmer.

3.

Check the installation of the flue terminal and ensure it is not obstructed.

Note:

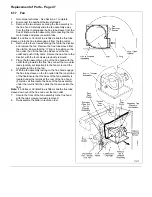

A flue sampling point has been provided on this boiler. It is accessible after removal of the white front case, and

removal of the 17mm A/F hexagon head bolt from the combustion chamber cover.

If it is necessary to dismantle the boiler the following checks should be made.

1.

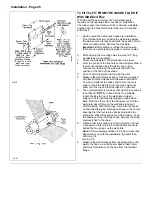

Remove the combustion fan and ensure that it is clean and free of debris. Check the impellor for freedom of

rotation.

2.

Remove the combustion chamber front and check if the burner or heat exchanger requires cleaning.

3.

Examine the main injector orifice and ensure it is clear and undamaged.

4.

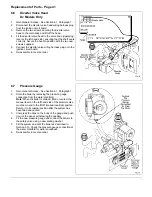

If a sufficiently large pilot flame cannot be achieved examine the pilot injector orifice to ensure it is clear and

undamaged. (See Fig. 54).

5.

When refitting the inner case front panel check that the seals are in good condition and compress satisfactorily.

On completion of the service run the boiler and ensure that it operates satisfactorily.

The Boiler Model and Serial Number/Code, are given on the Data Badge.

The boiler data label is on the left hand side of the chassis next to the gas valve.

WARNING

Before commencing work open the control panel cover (hinges down) and turn the thermostat knob to O (Off).

Allow the boiler to cool, isolate the electricity supply and turn off the gas at the gas service cock.

IMPORTANT

Always test for gas soundness after completing any servicing of gas carrying components and carry out functional

checks of controls.

Содержание Ultra 2

Страница 6: ...Installation Requirements Page 6 Fig 1 ...

Страница 7: ...Installation Requirements Page 7 Fig 2 ...

Страница 9: ...Installation Requirements Page 9 ...

Страница 37: ...Routine Maintenance Page 37 ...

Страница 51: ...7 Wiring Diagrams Page 51 ...

Страница 52: ...Wiring Diagrams Page 52 Ultra 2Dv ...

Страница 53: ...Wiring Diagrams Page 53 Ultra 2 ...

Страница 54: ...54 Fault Finding Part No 405 0522 8 Fault Finding Guide Page 54 ...

Страница 55: ...Part No 405 0522 Fault Finding 55 Fault Finding Guide Page 55 ...

Страница 56: ...56 Fault Finding Part No 405 0522 Fault Finding Guide Page 56 ...

Страница 57: ...Part No 405 0522 Fault Finding 57 Fault Finding Guide Page 57 ...

Страница 58: ...9 Short List Of Spare Parts Page 58 ...