3. Both connections are clearly marked.

4. Remove all burrs and debris from the joints and fittings.

5. Horizontal lengths of exhaust vent must be installed with

a slope of not less than 1/4" per foot (21mm per meter)

toward the boiler to allow condensate to drain from the

vent pipe. If the vent pipe must be piped around an

obstacle that causes a low point in the piping, a drain

with an appropriate trap must be installed.

6. All piping must be fully supported. Use pipe hangers

at a minimum of 4 foot (1.22 meter) intervals to

prevent sagging of the pipe.

7. Exhaust and air inlet piping is to be supported

separately and should not apply force to the boiler.

8. Penetration openings around the vent pipe and air

intake piping are to be fully sealed to prevent exhaust

gases from entering building structures.

9. PVC & CPVC Piping:

a. Use only solid PVC or CPVC Schedule 40 or 80

pipe for exhaust venting. Cellular core PVC or

CPVC is not approved for exhaust vent.

b. All joints must be properly cleaned, primed and

cemented. Use only cement and primer approved

for use with PVC or CPVC pipe that conforms to

ANSI/ASTM D2564.

c. A straight coupling is provided with the boiler to

be used as an outside vent termination. One of

the two screens is to be installed to prevent birds

or rodents from entering.

d. An air intake tee is provided with the boiler to be

used as an outside air intake termination. A screen

is to be installed to prevent birds or rodents from

entering.

e. The following are optional combination air

intake/exhaust terminations that are available

separately from your PB Heat, LLC distributor for

use with

P

URE

F

IRE

boilers.

f.

Refer to Figures 3.3 to 3.6 for sidewall venting

options using PVC or CPVC pipe.

g. Refer to Figures 3.7 & 3.8 for vertical venting

options using PVC or CPVC pipe.

F.

EXHAUST TAPPING FOR VENT SAMPLE

To properly install the boiler, carbon dioxide (CO

2

) and

carbon monoxide (CO) readings are to be determined

from a sample of combustion gases from the vent pipe.

To do this a hole must be drilled in the vent pipe.

a. Drill a 21/64" diameter hole in the exhaust vent

pipe from 6” to 12" from the outlet of the boiler.

b. Tap the hole with a 1/8" NPT pipe tap.

c. Use a 1/8" NPT, PVC Pipe Plug to seal the hole.

G. BOILER REMOVAL FROM COMMON

VENTING SYSTEM

If removing an existing boiler from a common vent

system the following steps must be carried out for each

appliance that remains connected. These steps are to be

completed for each appliance while the other appliances

that remain connected are not in operation.

a. Seal any unused openings in the common venting

system.

b. Visually inspect the venting system for proper size

and horizontal pitch. Verify that there is no

blockage or restriction, leakage, corrosion, and

other deficiencies which could cause an unsafe

condition.

c. Where practical, close all building doors and

windows. This includes interior doors between the

space in which the appliances remaining

connected to the common venting system are

located and other interior spaces in the building.

d. Turn on clothes dryers and any other appliance

not connected to the common venting system.

Exhaust fans such as range hoods or bathroom

exhaust fans are to be operated at their maximum

speed (Do not operate a summer exhaust fan).

e. Close fireplace dampers.

f.

Place the appliance that is being inspected in

operation. Follow the lighting instructions and

adjust the thermostat so that the appliance will

operate continuously.

g. Test for spillage at the draft hood relief opening

after 5 minutes of main burner operation. Use the

flame from a match or candle, or smoke from a

cigarette, cigar, or pipe.

h. After each appliance remaining connected to the

common vent system has been determined to vent

properly as outlined above, doors, windows,

exhaust fans, fireplace dampers and any other gas

burning appliance are to be returned to their

previous condition of use.

i.

Any improper operation of the common venting

system should be corrected at once so that the

installation conforms with the National Fuel Gas

Code, ANSI Z223.1/NFPA 54 and/or CAN/CGA

B149 Natural Gas and Propane Installation Code.

j.

When resizing any portion of the common venting

system, it the system should be resized to

approach the minimum size as determined using

the appropriate tables in Part 11 of the National

Fuel Gas Code, ANSI Z223.1/NFPA 54 and or

CAN/CSA B149.1, Natural Gas and Propane

Installation Code.

9

VENTING & AIR INLET PIPING

Description

Stock Code

3" PVC Concentric Vent Termination Kit

91403

3" Stainless Steel Vent Termination Kit

54161

Table 3.4: Vent Termination Kits

This appliance uses a positive pressure venting

system. All joints must be sealed completely to

prevent leakage of flue products into living spaces.

Failure to do this may result in severe personal injury,

death or major property damage.

WARNING

Содержание PF-110

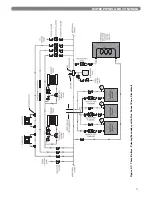

Страница 18: ...16 WATER PIPING AND CONTROLS Figure 4 6 Two Boilers Primary Secondary with Four Zones Zone Circulator ...

Страница 19: ...17 WATER PIPING AND CONTROLS Figure 4 7 Three Boilers Primary Secondary with Five Zones Zone Circulator ...

Страница 20: ...18 WATER PIPING AND CONTROLS Figure 4 8 Three Boilers Primary Secondary with Four Zones Zone Valves ...

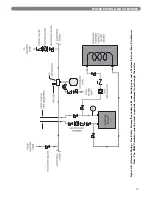

Страница 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

Страница 56: ...54 REPAIR PARTS ...

Страница 58: ...56 REPAIR PARTS ...

Страница 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Страница 61: ...59 APPENDIX A STATUS SCREENS ...

Страница 62: ...60 APPENDIX A STATUS SCREENS ...

Страница 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Страница 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Страница 65: ...63 APPENDIX C INSTALLER MENU ...

Страница 66: ...64 APPENDIX C INSTALLER MENU ...

Страница 68: ...66 NOTES ...

Страница 69: ...67 NOTES ...