A. GENERAL

1.

P

URE

F

IRE

™

boilers are supplied completely assembled

as packaged boilers. The package should be inspected

for damage upon receipt and any damage to the unit

should be reported to the shipping company and

wholesaler. This boiler should be stored in a clean, dry

area.

2. Carefully read these instructions and be sure to

understand the function of all connections prior to

beginning installation. Contact your PB Heat, LLC

Representative for help in answering questions.

3. This boiler must be installed by a qualified contractor.

The boiler warranty may be voided if the boiler is not

installed correctly.

4. A hot water boiler installed above radiation or as

required by the Authority having jurisdiction, must be

provided with a low water fuel cut-off device either as

part of the boiler or at the time of installation.

5. This boiler can be installed at high altitudes above

5,000 feet with no burner adjustments. This applies to

boilers equipped for firing natural gas or liquefied

petroleum (LP) gas.

B. CODES & REGULATIONS

1. Installation and repairs are to be performed in strict

accordance with the requirements of state and local

regulating agencies and codes dealing with boiler and

gas appliance installation.

2. In the absence of local requirements the following

should be followed:

a. ASME Boiler and Pressure Vessel Code, Section

IV - “Heating Boilers”

b. ASME Boiler and Pressure Vessel Code, Section

VI - “Recommended Rules for the Care and

Operation of Heating Boilers”

c. ANSI Z223.1/NFPA 54 - “National Fuel Gas Code”

d. ANSI/NFPA 70 - “National Electrical Code”

e. ANSI/NFPA 211 - “Chimneys, Fireplaces, Vents

and Solid Fuel Burning Appliances”

3. Where required by the authority having

jurisdiction, the installation must conform to the

Standard for Controls and Safety Devices for

Automatically Fired Boilers, ANSI/ASME CSD-1.

**

Please read if installing in Massachusetts**

Massachusetts requires manufacturers of Side Wall

Vented boilers to provide the following information

from the Massachusetts code:

·

A hard wired carbon monoxide detector with an

alarm and battery back-up must be installed on

the floor level where the gas equipment is to be

installed AND on each additional level of the

dwelling, building or structure served by the side

wall horizontal vented gas fueled equipment.

·

In the event that the side wall horizontally vented

gas fueled equipment is installed in a crawl space

or an attic, the hard wired carbon monoxide

detector with alarm and battery back-up may be

installed on the next adjacent floor level.

·

Detector(s) must be installed by qualified licensed

professionals.

·

APPROVED CARBON MONOXIDE

DETECTORS: Each carbon monoxide detector

shall comply with NFPA 720 and be ANSI/UL

2034 listed and IAS certified.

·

SIGNAGE: A metal or plastic identification plate

shall be permanently mounted to the exterior of

the building at a minimum height of eight (8) feet

above grade directly in line with the exhaust vent

terminal for the horizontally vented gas fueled

heating appliance or equipment. The sign shall

read, in print size no less than one-half (1/2) inch

in size,

“GAS VENT DIRECTLY BELOW.

KEEP CLEAR OF ALL OBSTRUCTIONS”

.

·

EXEMPTIONS to the requirements listed above:

°

The above requirements do not apply if the

exhaust vent termination is seven (7) feet or

more above finished grade in the area of the

venting, including but not limited to decks and

porches.

°

The above requirements do not apply to a

boiler installed in a room or structure separate

from the dwelling, building or structure used in

whole or in part for residential purposes.

·

The boiler installation manual, vent manufacturer's

installation manual, and this supplement shall

remain with the boiler at the completion of the

installation.

See the latest edition of Massachusetts Code 248 CMR

for complete verbage and also for additional (non-vent

related) requirements (248 CMR is available online).

If your installation is NOT in Massachusetts, please

see your authority of jurisdiction for requirements that

may be in effect in your area. In the absence of such

requirements, follow the

National Fuel Gas Code

,

ANSI Z223.1/NFPA 54 and/or CAN/CSA B149.1,

Natural Gas and Propane Installation Code

.

2

PREINSTALLATION

1. PREINSTALLATION

Liquefied Petroleum (LP) Gas or Propane is heavier

than air and, in the event of a leak, may collect in low

areas such as basements or floor drains. The gas

may then ignite resulting in a fire or explosion.

WARNING

Содержание PF-110

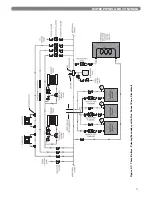

Страница 18: ...16 WATER PIPING AND CONTROLS Figure 4 6 Two Boilers Primary Secondary with Four Zones Zone Circulator ...

Страница 19: ...17 WATER PIPING AND CONTROLS Figure 4 7 Three Boilers Primary Secondary with Five Zones Zone Circulator ...

Страница 20: ...18 WATER PIPING AND CONTROLS Figure 4 8 Three Boilers Primary Secondary with Four Zones Zone Valves ...

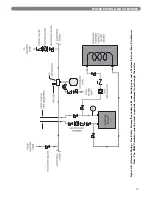

Страница 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

Страница 56: ...54 REPAIR PARTS ...

Страница 58: ...56 REPAIR PARTS ...

Страница 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Страница 61: ...59 APPENDIX A STATUS SCREENS ...

Страница 62: ...60 APPENDIX A STATUS SCREENS ...

Страница 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Страница 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Страница 65: ...63 APPENDIX C INSTALLER MENU ...

Страница 66: ...64 APPENDIX C INSTALLER MENU ...

Страница 68: ...66 NOTES ...

Страница 69: ...67 NOTES ...