A. GENERAL

1. Size water supply and return piping in accordance

with system requirements. Do not use smaller

diameter piping than the boiler connections.

2. If the

P

URE

F

IRE

boiler is used to replace an existing

boiler, make sure that the system piping is thoroughly

cleaned and free from debris before installing this boiler.

3. In hydronic systems where sediment may exist, install

a strainer in the boiler return piping to prevent large

particles and pipe scale from entering the boiler heat

exchanger. Use a large mesh screen in the strainer.

4. Install this boiler so that the gas ignition system

components are protected from water (dripping,

spraying, etc.) during operation and service (circulator

replacement, condensate trap cleaning, sensor

replacement, etc.).

B. OPERATING PARAMETERS

1. The

P

URE

F

IRE

boiler is designed to operate in a closed

loop hydronic system under forced circulation. This

requires the system to be completely filled with water

and requires a minimum water flow through the boiler

to operate effectively.

2. The minimum system pressure is 14.5 PSI (69 kPa)

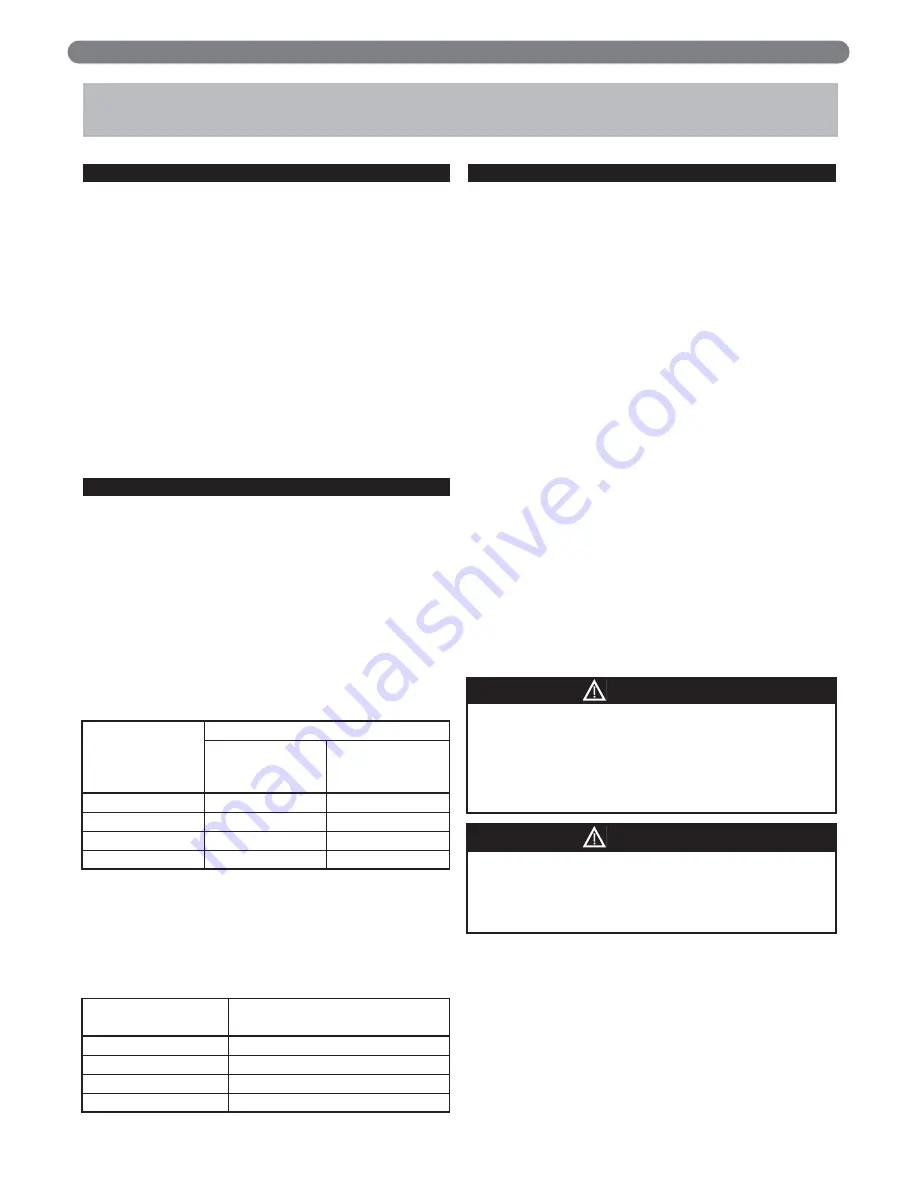

3. Table 4.1 lists the minimum flow rates for each

P

URE

F

IRE

model. If a glycol solution is to be used,

contact your PB Heat, LLC representative for

minimum flow rates.

Section 4.E provides detailed information about using

glycol for freeze protection.

Table 4.2 provides the water volume of the heat

exchanger including the supply and return pipes that

are attached at the factory.

C. SYSTEM COMPONENTS

Figure 4.1 shows the symbol key for piping diagrams in

this section. The following are brief descriptions of system

components.

1.

Pressure/Temperature Gauge:

A combination

pressure/temperature gauge is provided with each

P

URE

F

IRE

boiler to be mounted in the piping from the

boiler supply to the system as shown in Figure 4.2.

Most local codes require this gauge.

2.

Air Elimination:

Any closed loop hydronic system in

which the

P

URE

F

IRE

boiler is installed must have an air

elimination device. As the system water is heated,

dissolved oxygen and carbon dioxide will separate

from the liquid.

An air elimination device (such as a TACO 430 Series

Air Scoop with automatic air vent) is required to

remove the dissolved gasses from the system

preventing corrosion in the piping system and

eliminating system noise.

3.

Expansion Tank:

An expansion tank (such as a Bell &

Gossett Series HFT) is required to provide room for

expansion of the heating medium (water or glycol

solution). Consult the expansion tank manufacturer's

instructions for specific information regarding

installation. The expansion tank is to be sized for the

required system volume and capacity. In addition, be

sure that the expansion tank is sized based on the

proper heating medium. Glycol solutions may expand

more than water for a similar temperature rise.

4.

Y-Type Strainer:

In older systems where a significant

amount of sediment may be present, it may be

necessary to install a Y-type strainer. The strainer

should be checked often and cleaned during the first

few months of operation to assure that sediment does

not reach the heat exchanger and clog the passages.

Use a large mesh screen in the strainer.

10

WATER PIPING AND CONTROLS

4. WATER PIPING & CONTROLS

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Unlike automotive antifreeze, solutions for hydronic

applications contain corrosion inhibitors that will

protect system components from premature failure

due to corrosion.

CAUTION

Use only inhibited propylene glycol solutions which

are specifically formulated for hydronic systems.

Ethylene glycol is toxic and may cause any

environmental hazard if a leak or spill occurs.

WARNING

P

URE

F

IRE

Model

Minimum Flow Rate

Water

GPM (LPM)

50% Glycol

Solution

GPM (LPM)

PF-50

2.2 (8.3)

2.8 (10.6)

PF-80

3.3 (12.5)

4.1 (15.5)

PF-110

4.4 (16.7)

5.5 (20.8)

PF-140

5.5 (20.8)

6.8 (25.7)

Table 4.1: Minimum Flow Rate

P

URE

F

IRE

Model

Total Water Capacity

Gallons (Liters)

PF-50

0.62 (2.35)

PF-80

0.72 (2.73)

PF-110

0.89 (3.37)

PF-140

1.25 (4.73)

Table 4.2: Heat Exchanger Water Capacity

Содержание PF-110

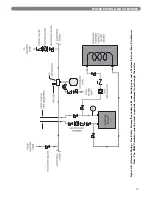

Страница 18: ...16 WATER PIPING AND CONTROLS Figure 4 6 Two Boilers Primary Secondary with Four Zones Zone Circulator ...

Страница 19: ...17 WATER PIPING AND CONTROLS Figure 4 7 Three Boilers Primary Secondary with Five Zones Zone Circulator ...

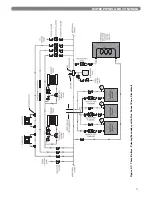

Страница 20: ...18 WATER PIPING AND CONTROLS Figure 4 8 Three Boilers Primary Secondary with Four Zones Zone Valves ...

Страница 30: ...28 ELECTRICAL CONNECTIONS Figure 7 4 Internal Wiring Schematic ...

Страница 56: ...54 REPAIR PARTS ...

Страница 58: ...56 REPAIR PARTS ...

Страница 60: ...58 APPENDIX A STATUS SCREENS APPENDIX A STATUS SCREENS ...

Страница 61: ...59 APPENDIX A STATUS SCREENS ...

Страница 62: ...60 APPENDIX A STATUS SCREENS ...

Страница 63: ...61 APPENDIX B USER MENU APPENDIX B USER MENU ...

Страница 64: ...62 APPENDIX C INSTALLER MENU APPENDIX C INSTALLER MENU ...

Страница 65: ...63 APPENDIX C INSTALLER MENU ...

Страница 66: ...64 APPENDIX C INSTALLER MENU ...

Страница 68: ...66 NOTES ...

Страница 69: ...67 NOTES ...