No. SX-DSV02829 -

79-

5)

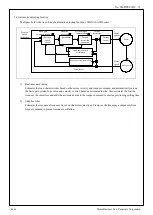

How to Operate

When Pr 0.02 (Setup of real-time auto-gain tuning mode) is set to a value other than 0, control parameter is

automatically set according to Pr0.03 “Real-time auto-tuning machine stiffness setup”.

When the servo is ON, enter operation command after about 100ms. When the load characteristic is correctly

estimated, Pr 0.04 Inertia ratio is updated. With certain mode settings, Pr 6.07 Torque command addition value,

Pr 6.08 Positive direction torque compensation value and Pr 6.09 Negative direction torque compensation value

will be changed.

When value of Pr0.03 “Real-time auto-tuning machine stiffness setup” is increased, the motor responsiveness

will be improved. Determine the most appropriate stiffness in relation to the positioning setup time and vibration

condition.

Note) The positive direction of feedback scale (after reversal of direction of Pr3.26 "Feedback scale &

CS reversal") always serves as positive.

6)

Other cautions

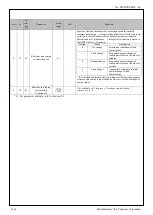

[1] Immediately after the first servo-on upon start up; or after increasing Pr0.03 “Real-time auto-tuning machine

stiffness setup”, abnormal sound or oscillation may be generated until the load characteristics is stabilized. If

such abnormality lasts or repeats for 3 or more reciprocating operations, take the following countermeasures.

1) Lower the setting value of Pr0.03 “Real-time auto-tuning machine stiffness setup”.

2) Set Pr 0.02 Real-time auto-tuning setup to 0 to disable the real-time auto-tuning.

3) Set Pr 0.04 Inertia ratio to the calculational value of the equipment and set Pr 6.07 Torque command

addition value, Pr 6.08 Positive direction torque compensation value and Pr 6.09 Negative direction torque

compensation value to 0.

[2] When abnormal noise and oscillation occur, Pr 0.04 (Inertia ratio) or Pr 6.07 (Torque command additional

value), Pr 6.08 (Positive direction torque compensation value), Pr 6.09 (Negative direction torque

compensation value) might have changed to extreme values. Take the same measures as described in the setp 3)

above in these cases.

[3] Among the results of real-time auto-gain tuning, Pr 0.04 (Inertia ratio) and Pr 6.07 (Torque command

additional value), Pr 6.08 (Positive direction torque compensation value), Pr 6.09 (Negative direction torque

compensation value) will be written to EEPROM every 30 minutes. When you turn on the power again, the

auto-gain tuning will be executed using the latest data as initial values. If power is turned off within 30 minutes

after the end of tuning process, the result of the real-time auto-tuning is not saved. If the result is not saved,

manually write parameters to EEPROM and then turn off power.

[4] The control gain is updated when the motor is stopped. Therefore, if motor is not stopped because gain is

excessively low or commands are given continually in one direction, the change in Pr0.03 “Real-time

auto-tuning machine stiffness setup” may not be reflected. In this case, abnormal sound or oscillation may be

generated depending on the stiffness setting that is reflected after the motor stops.

After the stiffness setting is changed, be sure to stop the motor and check that the stiffness setting is reflected

before performing next operation.

Note) The positive direction of feedback scale (after reversal of direction of Pr3.26 "Feedback scale &

CS reversal") always serves as positive

R1.00

Motor Business Unit, Panasonic Corporation