3

.

Evacuation

3.1

Leak check of connection point

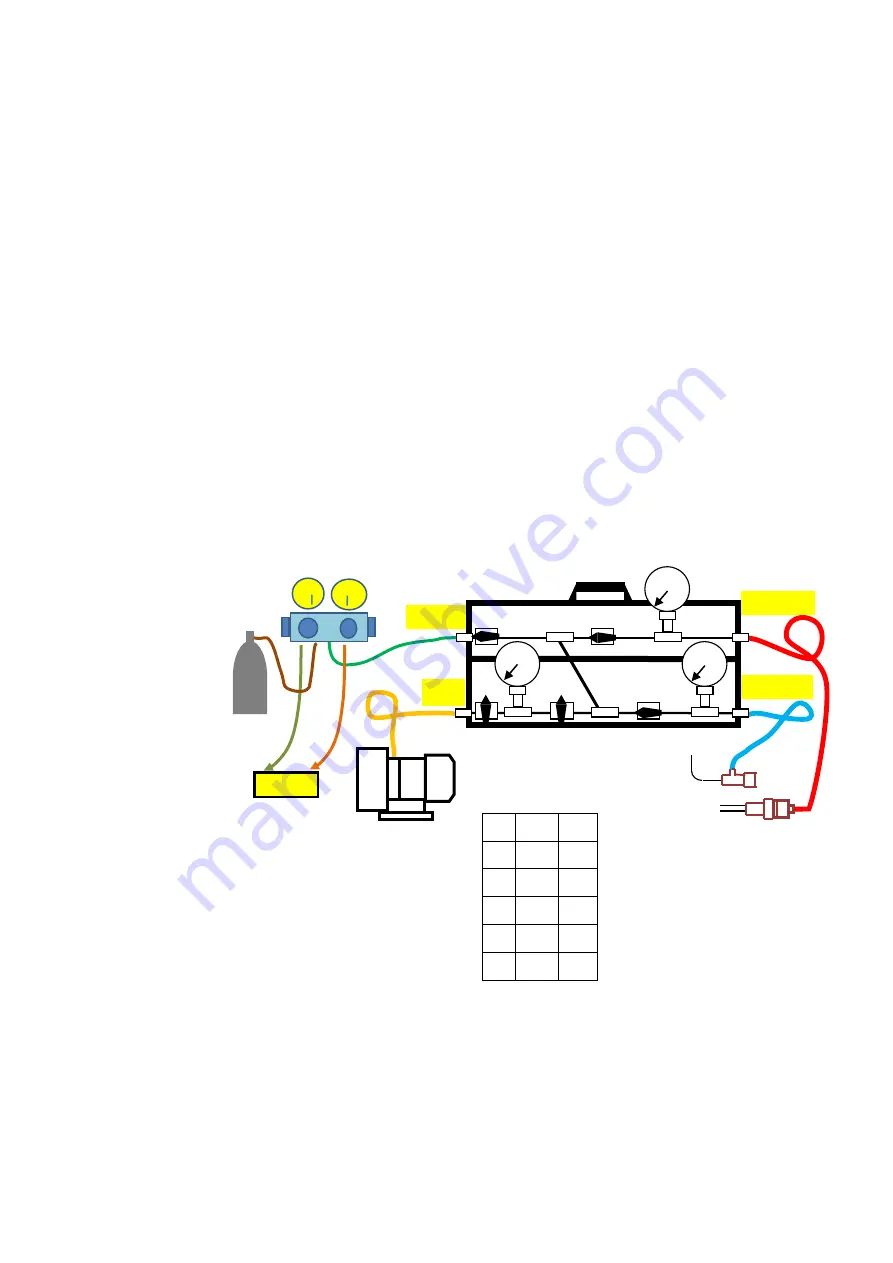

Preparation: Leak check spray (liquid detergent may be used), dedicated GM, general

purpose GM *, powerful vacuum pump, Nitrogen cylinder, charge hose,

branching equipment, tools

* In case of evacuating simultaneously on the low temperature side and the

high temperature side

Procedure: Connect as shown below and prepare for vacuum evacuation. When repairing

on the low temperature side was also done, add general purpose GM and

connect. ← Vacuum exhaust at the same time at high temperature and low

temperature for shortening the time

(In the case of only the high temperature side, connect the hose from the

nitrogen cylinder directly to the refrigerant port)

Open the unopened valves of nitrogen cylinders, VR, VL, VH and general

purpose GM,

Perform a leak check of the connection point. (Nitrogen replacement: provided

that the secondary pressure is 0.5 to 0.7 MPa)

Note

:

Use a leak check spray to check the gas leak at the connection point.

Generally, the explosion-proof vacuum pump has a small capacity, so prepare a

separate powerful vacuum pump.

(All flammable HC refrigerants are released, so there is no problem even if they are

not explosion-proof type)

Connection should be made surely without leakage.

Valve sate

open

shut

VC

○

VG

○

VL

○

VH

○

VR

○

Charge hose

Low pressure

service valve

High pressure

service valve

Low temp.

低温側

Nitrogen cylinder

General GM

Charge hose

VR

VG

VL

VC

VH

Refrigerant

port

Vacuum

port

High pressure

service port

Low pressure

service port

Dedicated GM

Explosion-proof

vacuum pump

-44-

Содержание MDF-DU502VH

Страница 8: ...Dimension MDF DU502VH 5 ...

Страница 9: ...MDF DU702VH 6 ...

Страница 17: ...Wiring Diagram 14 ...

Страница 18: ...main Circuit Diagram 15 ...

Страница 19: ...power 16 ...

Страница 20: ...USB 17 ...

Страница 73: ...WIRING YG Y Y GR B G W W W Y G R BL Y W R R BL R OR B BL R OR B Y W Y G Y G R BL 70 ...