MF 64

Author: Donato Gavino Murru [email protected]

Pag.

150

a

179

Pay attention to the working position adjustment of the cutting press,

not to hit any of the surrounding devices. Not doing so may result in

injuries or damage to the product.

For safety reasons, when recalling a recipe, the press adjustment need

to made with automatic button of the adjustment page on the touch

screen.

Now if the open and close positions are new (not by recalling one stored recipe), it is needed to set

the position trim tables first.

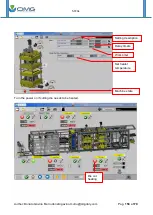

Entry in the Upper/Lower Trim table regulation from trim layout and use the jog buttons (arrows) to

freely move and reach, with the die tool, the position of cutting (it is the film material level). If some

adjustment of the day light is needed, use the adjustment of the upper table to arrive with the

toggles straight to touch the die cut blades with the strike plate.

Now, with this position set, you must input how much the travelling will be in order to press the

cutting die against the material. You must check the amount of distance and set the travelling

length in the propped field.

After, lower trim table position must be defined.

It is the same way as the upper trim table system.

Before every movement, especially after maintenance stops, re-setting

etc…. please be sure that the air pressure on the press regulator is

more than 4 bars. Not doing so may result in injury or devices damage.

Arrows buttons

to jog device

movement.

Travelling input

data field.

Field to set

travelling height.

Arrows buttons

to jog device

movement.

Содержание MF 64

Страница 24: ...MF 64 Author Donato Gavino Murru donato gavino murru omgitaly com Pag 23 a 179 Left Side Fixed safety guards...

Страница 25: ...MF 64 Author Donato Gavino Murru donato gavino murru omgitaly com Pag 24 a 179 Right Side Fixed safety guards...

Страница 31: ...MF 64 Author Donato Gavino Murru donato gavino murru omgitaly com Pag 30 a 179 SRP CS components...