Maintenance

Description

item No.

2FD/2FF/2FG-3.0

1-4-38

U112

Setting toner refresh operation

Description

Sets the drum refresh operation time and the developing bias on time at power on and after copying.

Purpose

To change the drum refresh operation time and the developing bias on time at power on and after copying if

image flow level is low.

Method

Press the start key. The screen for executing is displayed.

Setting

1. Select the item to be set. The selected item is displayed in reverse.

2. Change the setting using the cursor up/down keys.

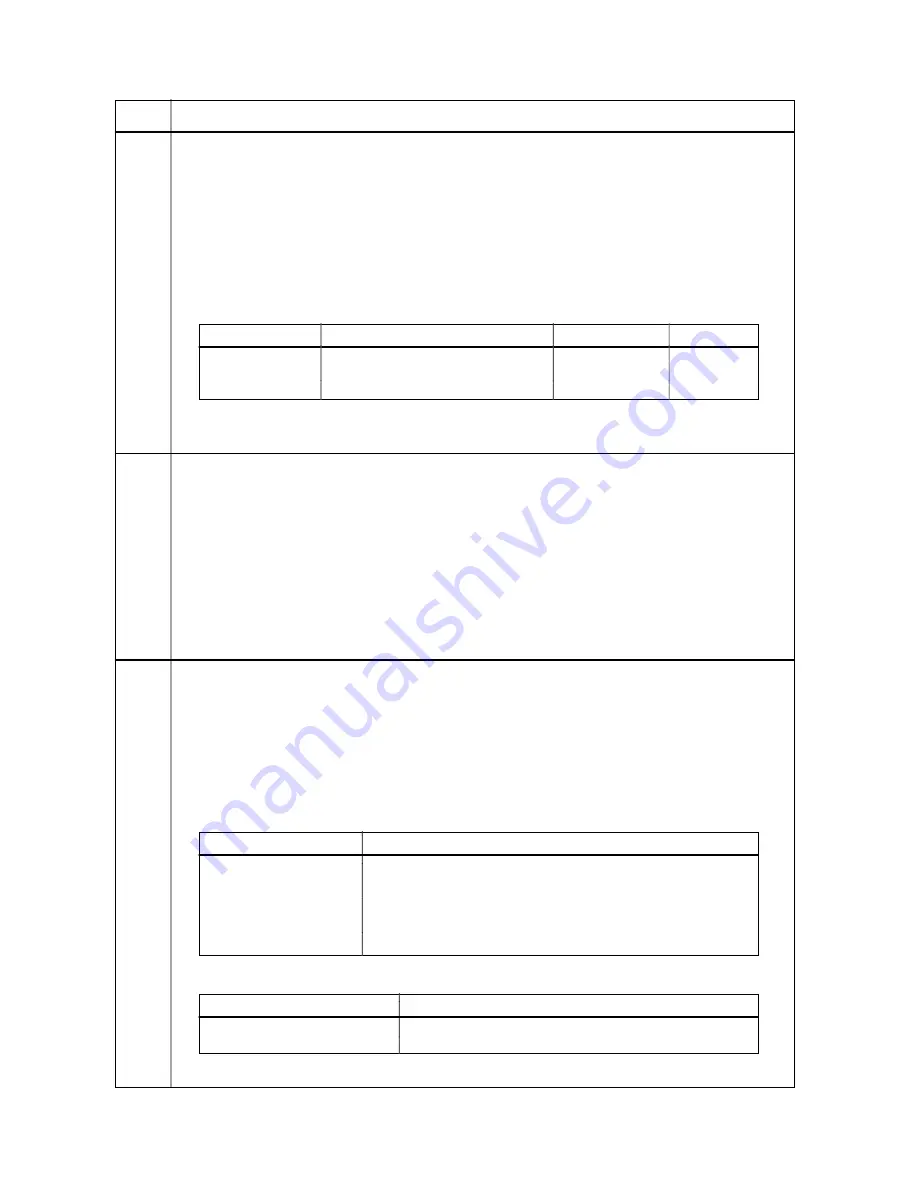

Display

Description

Setting range

Initial setting

ON TIME(SEC)

Toner refresh operation time

50 to 150 (sec)

120

BIAS TIME(MSEC)

Developing bias on time

500 to 1000 (msec) 700 (30 cpm)

540 (40/50 cpm)

3. Press the start key. The value is set.

Completion

Press the stop/clear key. The screen for selecting a maintenance item No. is displayed.

U113

Performing drum refresh operation

Description

Executes drum refresh operation.

Purpose

To operate when image flow occurs.

Method

1. Press the start key. The screen for executing is displayed.

2. Press the start key. Drum refresh operation starts. (approximately 3 minutes)

3. To stop the operation, press the stop/clear key.

Completion

Press the stop/clear key when the operation stops. The screen for selecting a maintenance item No. is

displayed.

U114

Setting separation charger mode

Description

Specifies Separation Charger (SC) Whole mode to ON/OFF, and the temperature/humidity of which SC Whole

mode is ON.

Purpose

If the paper wrinkles from causes other than low temperature or low humidity (20 °C/ 50 % RH or less), change

the temperature/humidity. If the fixing offset occurs, switch SC Whole mode to OFF.

Method

1. Press the start key. The screen for selecting an item is displayed.

2. Select the item to be set and press the start key. The screen for executing each item is displayed.

Display

Description

SELECT SC WHOLE MODE Specifying SC Whole mode to ON/OFF

SELECT TEMP, HUM

Specifying the temperature/humidity of which SC Whole mode in ON.

SC Whole mode turns ON when the temperature/humidity becomes

the preset value or less.

SELECT VELLUM MODE

Specifying SC Whole mode to ON/OFF when using thin paper

SELECT NORMAL MODE Specifying SC Whole mode to ON/OFF when using plain paper

Setting: SELECT SC WHOLE MODE

1. Select either ON or OFF. The selected item is displayed in reverse.

Display

Description

ON

Selecting SC Whole mode

OFF

Not selecting SC Whole mode

Initial setting: ON

2. Press the start key. The setting is set, and the screen for selecting an item is displayed.

Содержание d-Copia 300

Страница 1: ...d Copia 300 d Copia 400 d Copia 500 SERVICE MANUAL Published in April 2005 842FG112 Version 3 0...

Страница 4: ...This page is intentionally left blank...

Страница 32: ...1 3 9 2FD 2FF 2FG 3 0 This page is intentionally left blank...

Страница 351: ......